Butterfly valves are an integral part of modern fluid control systems, playing a crucial role in regulating flow in various industries. Their design, efficiency, and versatility have made them a preferred choice in industrial and sanitary applications. Among these, butterfly valves and sanitary valves stand out for their specialized capabilities, addressing unique operational needs. These valves ensure seamless operations, whether in challenging industrial environments or hygienic settings requiring strict compliance.

This article delves into the features, applications, and benefits of these two critical types of butterfly valves, shedding light on their importance in modern engineering and industry.

Understanding High-Performance Valves

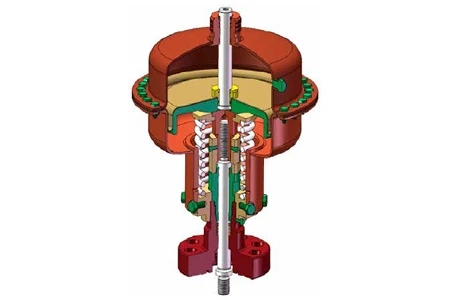

High-performance butterfly valves are designed to meet the demands of industries requiring robust and reliable equipment capable of handling extreme conditions. These valves excel in scenarios involving high pressures, extreme temperatures, and corrosive substances.

Key Features of Butterfly Valves

- Advanced Offset Design

- High-performance valves often utilize double-offset or triple-offset configurations. This design minimizes friction between the valve disc and the seal, reducing wear and extending the valve’s lifespan. The offset also ensures a tight shut-off, making the valve reliable even in high-stakes applications.

- Resilient Material Construction

- These valves are crafted from materials like stainless steel, carbon steel, and high-grade alloys. Such construction allows them to handle aggressive fluids, abrasive materials, and corrosive chemicals without compromising performance.

- High-Pressure and Temperature Tolerance

- Engineered to withstand extreme conditions, butterfly valves often operate efficiently in temperatures exceeding 450°F and handle pressures far beyond standard valves' capabilities.

Applications of High-Performance Valves

The resilience and precision of these valves make them indispensable in:

● Oil and Gas Industries: Managing crude oil, natural gas, and other hydrocarbons under high pressure.

● Power Generation Plants: Regulating steam and cooling systems in demanding environments.

● Chemical Processing: Handling reactive and corrosive chemicals with precision and safety.

● Marine Applications: Used in shipbuilding for seawater and ballast systems.

The versatility of butterfly valves ensures their relevance across multiple industrial sectors, where reliability and durability are paramount.

Sanitary Butterfly Valves: Designed for Hygienic Environments

In industries where cleanliness and hygiene are non-negotiable, sanitary butterfly valves serve as the perfect solution. These valves are specially designed to meet the stringent requirements of sectors like food processing, pharmaceuticals, and cosmetics.

Distinct Features of Sanitary Valves

- Smooth and Polished Surfaces

- The interior surfaces of butterfly valves are polished to eliminate crevices where debris or microorganisms could accumulate. This design ensures optimal hygiene and easy cleaning.

- Ease of Disassembly and Cleaning

- These valves are designed for quick disassembly, making them easy to clean and maintain. This feature is especially crucial in industries where contamination risks must be minimized.

- Compliant Materials

- Sanitary butterfly valves are typically made from food-grade stainless steel that complies with regulatory standards, such as FDA and EHEDG requirements, ensuring the safety of consumable products.

Applications of Sanitary Valves

● Food and Beverage Industry: Used for processes like pasteurization, bottling, and brewing.

● Pharmaceuticals: Ensures sterility during drug manufacturing.

● Dairy Production: Essential in handling milk and other dairy products without contamination.

●Cosmetics Manufacturing: Maintains purity when dealing with creams, lotions, and other products.

The hygienic design and regulatory compliance of sanitary butterfly valves make them indispensable in applications demanding the highest cleanliness standards.

The Common Benefits of Butterfly Valves

Whether high-performance or sanitary, butterfly valves offer several advantages that make them a preferred choice across industries.

Compact and Lightweight Design

Butterfly valves have a slim, lightweight construction, making them easy to install and operate, even in systems with limited space.

Cost-Effective Solution

Compared to other valve types, butterfly valves provide a budget-friendly option without compromising on performance or durability.

Efficient Operation

The quarter-turn mechanism allows for rapid opening and closing, enhancing process efficiency and control.

Minimal Maintenance Needs

With fewer moving parts and a robust design, butterfly valves require less maintenance, translating into lower operational costs over time.

Versatility

Butterfly valves can handle a wide range of media, including gases, liquids, and slurries, making them suitable for diverse industries.

Choosing Between High-Performance and Sanitary Valves

Selecting the appropriate valve type depends on your application and operational requirements.

- Operational Conditions:

○ For high-pressure or extreme-temperature systems, high-performance butterfly valves are ideal.

○ For processes requiring strict hygiene, butterfly valves are the better choice.

- Material and Regulatory Compliance:

- Ensure the valve’s material matches your application needs, whether handling aggressive chemicals or maintaining food-grade standards.

- Maintenance and Longevity:

- Consider the ease of cleaning and maintenance, especially for applications requiring frequent sanitation.

Understanding your system’s demands is key to making an informed choice between these two valve types.

Emerging Trends in Butterfly Valve Technology

The evolution of butterfly valves is driven by technological advancements and industry demands. Here are some notable trends shaping the future:

Integration of Smart Technology

Butterfly valves are increasingly equipped with IoT-enabled devices for real-time monitoring and control. These smart-systems provide data on valve performance, enabling predictive maintenance and reducing downtime.

Sustainability Focus

Manufacturers are adopting eco-friendly materials and processes to reduce the environmental impact of valve production. Enhanced coatings and seal materials further contribute to energy efficiency and sustainability.

Improved Durability

Advancements in material science have led to the development of valves with enhanced resistance to corrosion, abrasion, and chemical attacks.

These innovations promise to make butterfly valves even more efficient and reliable in diverse applications.

Best Practices for Butterfly Valve Maintenance

Proper maintenance is crucial for maximizing the lifespan and performance of butterfly valves. Here are some best practices:

- Regular Inspection:

- Periodically check for wear and tear, especially in seals and gaskets.

- Cleaning and Lubrication:

- For butterfly valves, ensure thorough cleaning to prevent contamination. Lubricate moving parts to ensure smooth operation.

- System Compatibility:

- Always verify that the valve is suitable for the operating conditions, including pressure, temperature, and media type.

- Timely Replacement:

- Replace worn-out components promptly to avoid system failures.

Following these guidelines ensures the long-term efficiency and reliability of your butterfly valves.

Conclusion

Both butterfly valves and sanitary butterfly valves serve as critical components in fluid control systems, each tailored to specific operational needs. High-performance valves are built for durability and precision in challenging industrial settings, while sanitary valves prioritize cleanliness and compliance in sensitive applications.

Understanding the unique features, benefits, and applications of these valves allows businesses to make informed decisions, optimizing system performance and ensuring regulatory compliance.

As industries evolve, advancements in butterfly valve technology will continue to enhance their functionality, reliability, and sustainability. Whether you’re managing high-pressure systems or maintaining strict hygiene standards, butterfly valves remain a trusted solution for modern fluid control challenges.