Bearings play an important role in many machines. They are donut-shaped pieces of material created and designed that limit the motion of a machine's moving components while eliminating friction between them. All bearings support the machines with which they are used, they are available in many different types.

Stay tuned to this page, and you will learn about bearing types and choosing the right bearing type. Keep going with this!

Thrust Bearings:

Thrust bearings are rotary bearings that are designed in a specific way to support an axial load. In other words, they can rotate along with a machine’s parts.

Thrust bearings help rotate a machine’s moving parts. Once the machine’s moving components start to rotate, they roll with the thrust bearings.

How Does Thrust Bearings Work

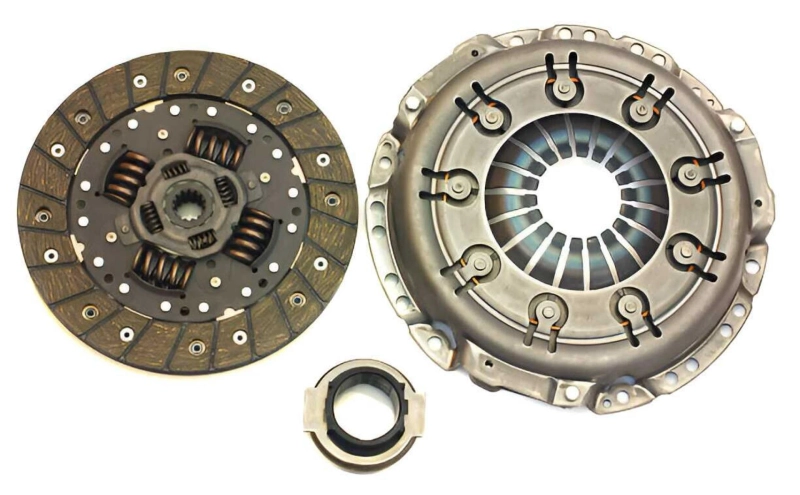

Many thrust bearings support machines using balls. These bearings have many little metal balls housed in a band around the perimeter. The photo above shows an example of a thrust ball bearing.

The application of thrust ball bearings is where a machine’s moving parts apply an axial load. With their arrangement of balls, they can help with the circling of a machine’s moving components.

Types Of Thrust Bearings:

Thrust bearings have other types. One is a cylinder thrust bearing, and the other is a magnetic thrust bearing.

Cylinder thrust bearings have cylindrical-shaped rollers that point towards the axis. The other type of thrust bearing is magnetic.

The magnetic thrust bearings live up to their name by creating a magnetic field. They are made using ferromagnetic materials to produce a magnetic field.

The presence of this magnetic field supports the axial thrust. None of the different types are more popular than ball thrust bearings. If you are searching for thrust ball bearings, you can get them from Decent Machinery, the best thrust ball bearings supplier.

Ball Bearings

Ball bearings are the most common type of bearing in the machinery world. You will find them in everything from inline skates to hard drives.

Ball bearings can easily handle both radial and thrust loads. They are usually found in applications with relatively small loads.

In a ball bearing, the load is passed from the outer race to the ball and from the ball to the inner race.

However, the ball comes in a sphere shape and only connects the inner and outer race at a very little point, which helps it spin smoothly.

This means there won't be much contact area carrying that load, so if the bearing gets overloaded, the balls can deform or squish, ruining the bearing.

How Ball Bearings Work:

Bearings are used to produce rotational or linear motion and to reduce friction and handling stress.

Like a wheel, the bearing enables the device to roll, reducing the friction between the bearing surface and its tumbling surface.

When friction is minimized, moving rotationally or linearly is very convenient, which also increases speed and efficiency.

Roller Bearings

Roller bearings are utilized in conveyor belt rollers, which must hold heavy radial loads. The roller is a cylinder in these bearings, so the connection between the inner and outer race is not a point but a line.

This will spread the load out to a bigger area, and it allows the bearing to handle heavier loads as compared to a ball bearing. However, this bearing type is not designed to handle that much loading.

A different variant of this type of bearing is called a needle bearing. It uses cylinders with a very small diameter and can fit into tight places.

How Roller Bearings Work:

Roller bearings, known as rolling-element bearings, are pretty much the same as ball bearings. They are created and designed to carry a load while eliminating friction.

Roller bearings transfer loads using cylinder rolling elements instead of balls to maintain the separation between the bearing's moving parts.

These bearings can have single or multiple rows of rolling elements, and multiple rows can significantly improve radial load capacity. The other roller shapes can reduce friction and support radial and axial loads.

Final Thoughts

You know the difference between thrust ball bearings and other bearing types. These bearing types work differently from others.

The application of every bearing type differs from others, and they are used in modern-day types of machinery.