Do you need to manufacture different kinds of components? Are you seeking a cost-effective method for parts production? Well, your solution is rapid tooling. It can have a significant impact on the process of prototyping. Many automotive parts manufacturers use this method because it maintains accurate components specification. Therefore, it helps to reduce manufacturing time and cost. It is an effective method to develop innovative products for many inventors and business people. When making the rapid prototype silicone parts, you should consider essential features. Let’s see some tips for choosing the right tooling company:

What services the company offers

You should pay attention to the service the tooling company offers. They use cutting-edge technology to provide the most excellent service for consumers. The top company offers various services such as sheet metal fabrication, rapid tooling, vacuum casting, and more.

Quality of products

It is essential to consider the quality of the product before choosing the tooling firm. They offer top-notch products for all sectors like automotive, healthcare, pharmaceutical, and more. The company uses quality materials to make components that can last for an extended period.

Look for machines

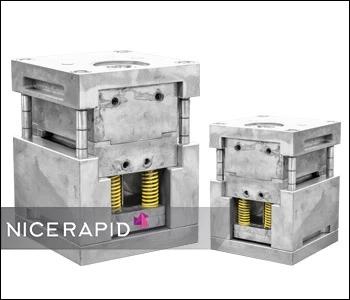

When choosing a rapid tooling prototyping company, you should consider the machines and techniques. The leading firm has innovative machinery and modern infrastructure to give quality products. Also, they will deliver many goods as quickly as possible.

Experience of experts

You need to look for the experience and qualifications of professionals. The reputable company hires experienced experts to provide exclusive goods for consumers. They understand the client's needs and give a better solution.

These features help you to select the most excellent tooling company. They have experienced experts to provide top-notch products for consumers. With this technology, you can obtain an extensive range of products quickly.