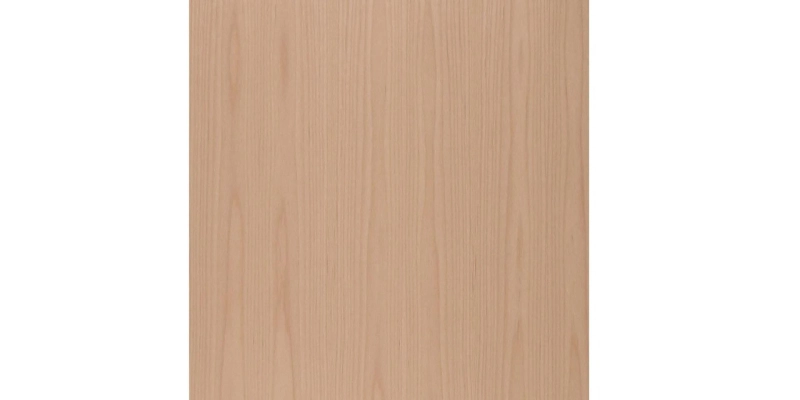

Alder is a popular hardwood that is renowned for its easy workability, both with hand tools and power equipment. It is also a popular wood commonly used to make alder veneer sheets and panels.

Alder wood often produces a uniform grain pattern that seems consistent and aesthetically pleasing, and, when used to produce alder veneer, can be quite economical and cost-effective to use, as opposed to solid hardwood.

Consequently, alder veneer has a wide range of popular uses, including but not limited to the following.

● Furniture making: One of the most popular applications of alder (and alder veneer) is to make accent furniture, including but not limited to tables, chairs and other seating, bed sets, bookcases, cupboards, shelves, and chests of drawers. Alder’s unique, pleasing warmth and even-grain orientation offer aesthetic balance, especially in interiors where wood’s natural beauty is prized, and in which the elements of Mission and Arts and Crafts schools of design are present.

● Paneling: Wainscoting with solid wood panels can be quite expensive and labor-intensive. Veneer can be applied over a variety of other surfaces/substrate materials to give the same impression at a lower cost, and, some high-quality substrate materials are less prone to warping, swelling, and cracking than solid wood.

● Cabinetry: Alder veneer is also a popular choice for decorating cabinetry as it is more affordable than solid wood, but produces the same aesthetic effects. In rustic interiors, special cuts of Alder veneer like knotty alder can be used to create a more bucolic impression.

Also, alder’s relatively affordable cost, paired with its unique aesthetic which outshines synthetics, makes it appealing not only for residential but also for commercial use.

When Buying Wood Veneer…

Before you buy wood veneer, alder or otherwise, consider the size and scope of your project, as well as how much you anticipate you will need to use.

The reason for this is that you don’t want to run out of veneer halfway through a project. It is nearly impossible to match the exact tone and grain patterning of veneer from another batch separate from the one you originally ordered, even of the same species and cut.

This is because veneer is a natural material and each individual tree will produce a unique grain figure and color tone.

This makes matching after the fact difficult, so make sure you buy as much veneer as you need up front, plus a little extra to give you some leeway.

Finishing Alder Veneer

Alder, though considered a hardwood, is a very soft, flexible wood that responds well to bending and finishing. This makes it highly suitable for use in cabinetry and furniture making.

It also makes alder veneer particularly easy to finish. While alder responds well to a wide range of stains and finishes, a popular method of finishing alder veneer is to apply a clear coat, which will preserve the warm notes of the wood, as well as its unique grain figure.

The first step in applying a clear coat is to sand the veneer; use hand tools (power tools increase the risk of sand-through) and polish down to a fairly high grit, like 800 or 1000. Always sand with the grain, not across or against it.

Then, apply a high-quality clear coat. Clear shellac, high-gloss lacquer, and both water and oil-based polyurethanes are good options that will protect the wood, promote its luster, and showcase its unique grain.

High-Quality Alder Veneer, Online

Looking for high-quality alder veneer sheets or panels for your next project? Visit Oakwood Veneer online or call them at 800-426-6018. They carry a wide range of alder veneer in different cuts, including knotty and pecky veneer, perfect for a wide range of woodworking projects.

Check out their catalog or get in touch with them today.

For More Information about Maple Edge Banding and Edge Banding Tape Please Visit: Oakwood Veneer Company.