Glyphosate is a highly effective, broad-spectrum, non-selective, and non-residue post-emergent herbicide. Since its commercialization, it has quickly become a post-emergent systemic, non-selective control of annual and perennial weeds. Leading herbicide.

Common name: glyphosate, white solid. Melting point 230 ℃.

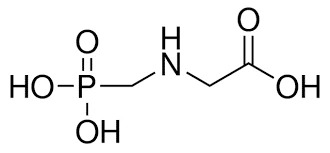

Molecular formula: C3H8NO5P

Molecular weight: 169.07

The solubility in water at 25°C is 12g/L, and the solubility in water at 25°C is 1.2%, and its isopropyl amine salt is completely soluble in water. Physical and chemical properties the appearance of 10% water agent is light brown liquid, the density is about 1.3 kg/L, non-flammable, and the pH value is 6-8.

Glyphosate production method:

- Aminoacetonitrile method: IDA is synthesized with aminoacetonitrile, oxidized to bisphosphonate and finally to glyphosate

- Dimethyl phosphite method

This refers to dividing the crystallization into two distinct stages.

We often say that the method of controlling supersaturation is a method that is often used in the laboratory state, and has a completely different treatment method in industrial applications.

- Control the temperature difference between the cooling medium and the circulating material, within 5 degrees or within 3 degrees.

- The heat exchange surface adopts high-grade polishing

- Coarse heat exchange tubes with a diameter of φ32 or more are used

- The flow rate of the heat exchange medium is controlled at 0.5-2 m/s. Frequency conversion control

- The crystal is in a good suspended state

Our approach in practical industrial applications:

- It mainly adopts the design of special heat exchange components to fundamentally solve the problems of scarring and pipe blockage. This is the core problem of crystallizer design.

- Segmental crystallization, take out relatively large crystals from one stage of crystallization and enter the crystallizer of the next stage and become the seeds of the next stage, avoid the state of mixed crystals, and finally achieve a qualified particle size.

- Use the method of recycling to effectively solve the problem of the impact of fine crystals on the system

- The special pipeline system prevents the pipeline from being blocked.

- Four-stage temperature control to obtain a reasonable temperature difference range

- Secondary liquid level control - control the speed of the pump rather than the opening of the valve in front of the pump.

- Effective stirring, the particles are in a fully suspended state.

0