Clean water is essential for both public health and industrial operations. One of the most critical steps in making water safe and usable is the Coagulation and Flocculation Water Treatment process. This method, while technical, is grounded in simple chemistry principles that play a vital role in removing suspended particles and other impurities from water.

In this blog, we will delve into the science behind Coagulation and Flocculation Process in Water Treatment, its importance, and real-world insights, while adhering to Google's latest content best practices.

What Is Coagulation and Flocculation?

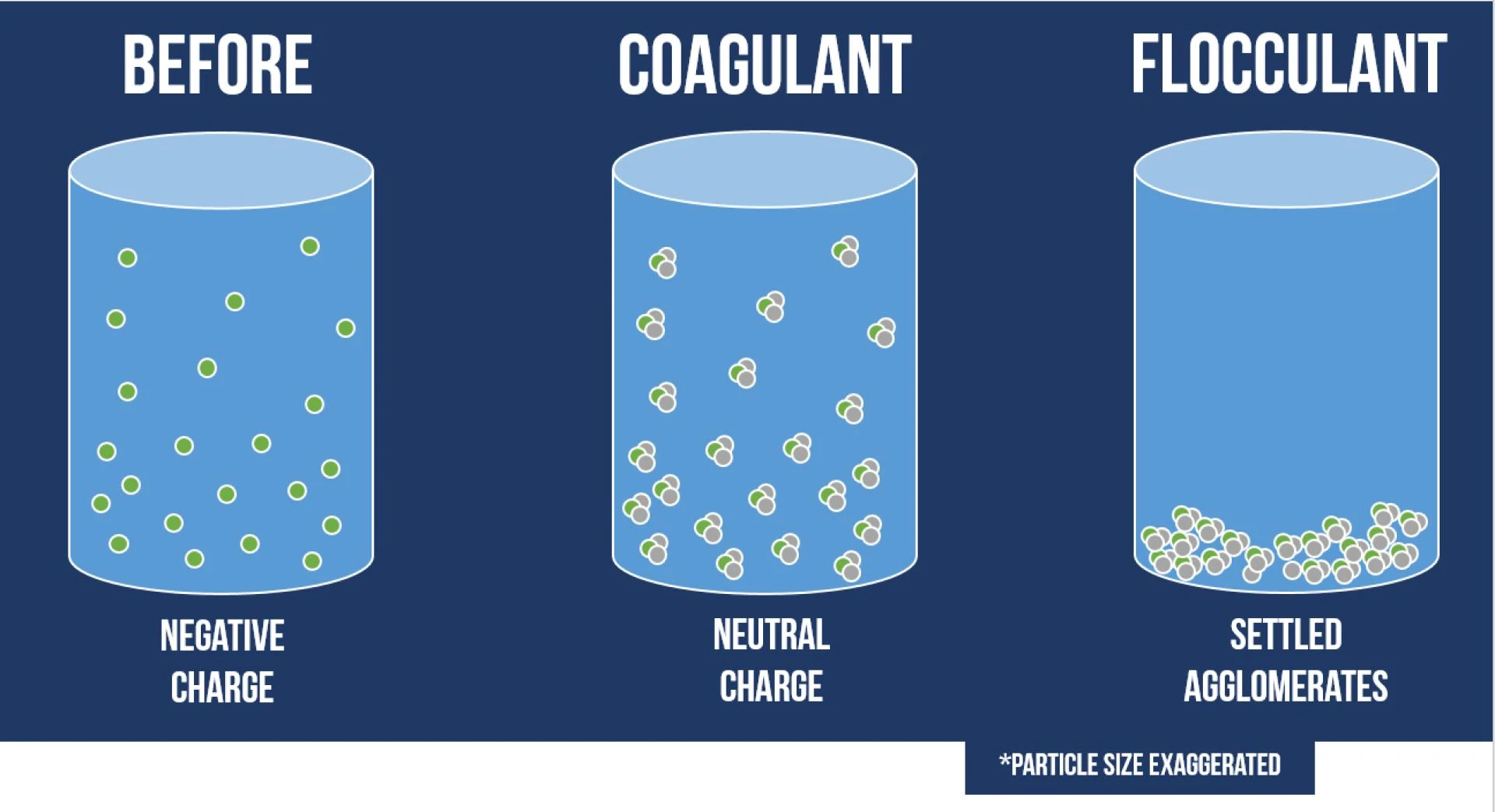

Coagulation and flocculation are two sequential steps used to treat water and wastewater. Though often mentioned together, each step serves a distinct function:

1. Coagulation

This is the initial stage where chemicals known as coagulants (commonly alum or iron salts) are added to the water. These chemicals carry a positive charge that neutralizes the negative charges on dissolved particles like dirt, bacteria, and organic matter. Once the charges are neutralized, the particles begin to clump together into tiny masses known as “microflocs.”

2. Flocculation

Following coagulation, the water is gently mixed to encourage the microflocs to collide and bind together, forming larger aggregates called flocs. These flocs are heavy enough to settle at the bottom or be filtered out effectively.

Why Coagulation and Flocculation Matter

The Coagulation and Flocculation Process in Water Treatment is not just a technical procedure—it’s a cornerstone of public safety and industrial efficiency. Here's why it matters:

- Removal of Suspended Solids: Helps in clearing up turbid water.

- Reduction of Pathogens: By aggregating microorganisms, it facilitates easier removal.

- Prepares Water for Further Treatment: Such as filtration and disinfection.

- Industrial Application: Essential in food processing, chemical manufacturing, and paper production.

Real-World Impact: What Experts Say

“We’ve seen a 75% improvement in filter efficiency after optimizing our coagulation and flocculation steps. It’s a game-changer.”

— Arvind Nair, Process Engineer, Municipal Water Authority

“What’s overlooked is how this process protects communities. It’s our first line of defense against waterborne contaminants.”

— Dr. Sheila Roy, Environmental Scientist

These testimonials echo a consistent theme: Coagulation and Flocculation Water Treatment isn’t just effective; it’s essential.

Step-by-Step Breakdown of the Process

To better understand this vital process, here is a simplified breakdown:

Step

Description

Coagulation

Chemical is added to destabilize particles

Rapid Mixing

Ensures even distribution of the coagulant

Flocculation

Gentle mixing to form larger flocs

Sedimentation

Flocs settle out, clarifying the water

Filtration

Remaining particles are removed using filters

Each step must be optimized for water type, chemical dosage, and mixing conditions to ensure maximum efficacy.

Frequently Asked Questions

Q: What chemicals are commonly used in coagulation?

A: Common coagulants include aluminum sulfate (alum), ferric chloride, and polyaluminum chloride. The choice depends on water characteristics.

Q: Is this process safe for drinking water?

A: Yes. All chemicals used are approved and rigorously tested for safety in potable water systems.

Q: Can it remove all impurities?

A: While effective at removing suspended solids and some microorganisms, coagulation and flocculation are typically followed by filtration and disinfection for comprehensive treatment.

Environmental and Regulatory Considerations

Modern Coagulation and Flocculation Water Treatment processes are closely aligned with environmental standards. Waste sludge generated from floc sedimentation must be disposed of according to local regulations to prevent environmental harm.

Moreover, water treatment facilities must comply with guidelines set by organizations such as the EPA (Environmental Protection Agency) and WHO (World Health Organization), ensuring consistent public safety.

Final Thoughts

The Coagulation and Flocculation Process in Water Treatment and Wastewater Storage serves as a backbone for many water purification systems. It transforms murky, particle-laden water into a cleaner state, making it easier to filter, disinfect, and safely consume or use in industrial settings.