In the rapidly evolving world of engineering and design, Finite Element Analysis (FEA) stands out as one of the most powerful and indispensable tools. FEA Engineering allows complex structures, systems, and components to be analyzed under various physical conditions without the need for expensive, time-consuming prototypes. It plays a crucial role across multiple industries, including aerospace, automotive, civil engineering, and electronics. This article delves into the fundamentals of FEA, its key applications, benefits, challenges, and future trends.

What is FEA Engineering?

FEA, or Finite Element Analysis, is a numerical method used to solve complex structural, thermal, fluid, and multiphysics problems. In simple terms, it involves breaking down a large, complicated system into smaller, manageable parts called finite elements. Each element is analyzed individually using mathematical models, and the collective behavior of all elements is combined to predict the performance of the entire system.

FEA Engineering, therefore, refers to the discipline of applying this method to design, test, and optimize products and structures before they are physically built. Engineers use specialized software like ANSYS, ABAQUS, SolidWorks Simulation, and COMSOL Multiphysics to carry out FEA.

How Does FEA Work?

The basic process of FEA consists of several key steps:

- Preprocessing: The object or structure to be analyzed is modeled in 2D or 3D space. It is then divided into a finite number of small elements using a process called meshing. Each element is assigned material properties (like elasticity, density, thermal conductivity).

- Applying Loads and Boundary Conditions: External forces, pressures, temperatures, or other physical effects are applied to the model. Boundary conditions, such as fixed supports or frictionless contacts, are also defined.

- Solving: The FEA software solves the governing mathematical equations (usually differential equations) for each element, considering the loads and constraints.

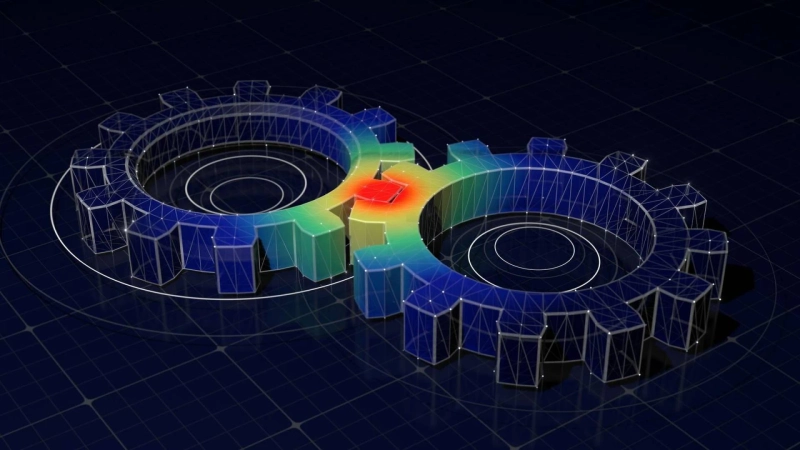

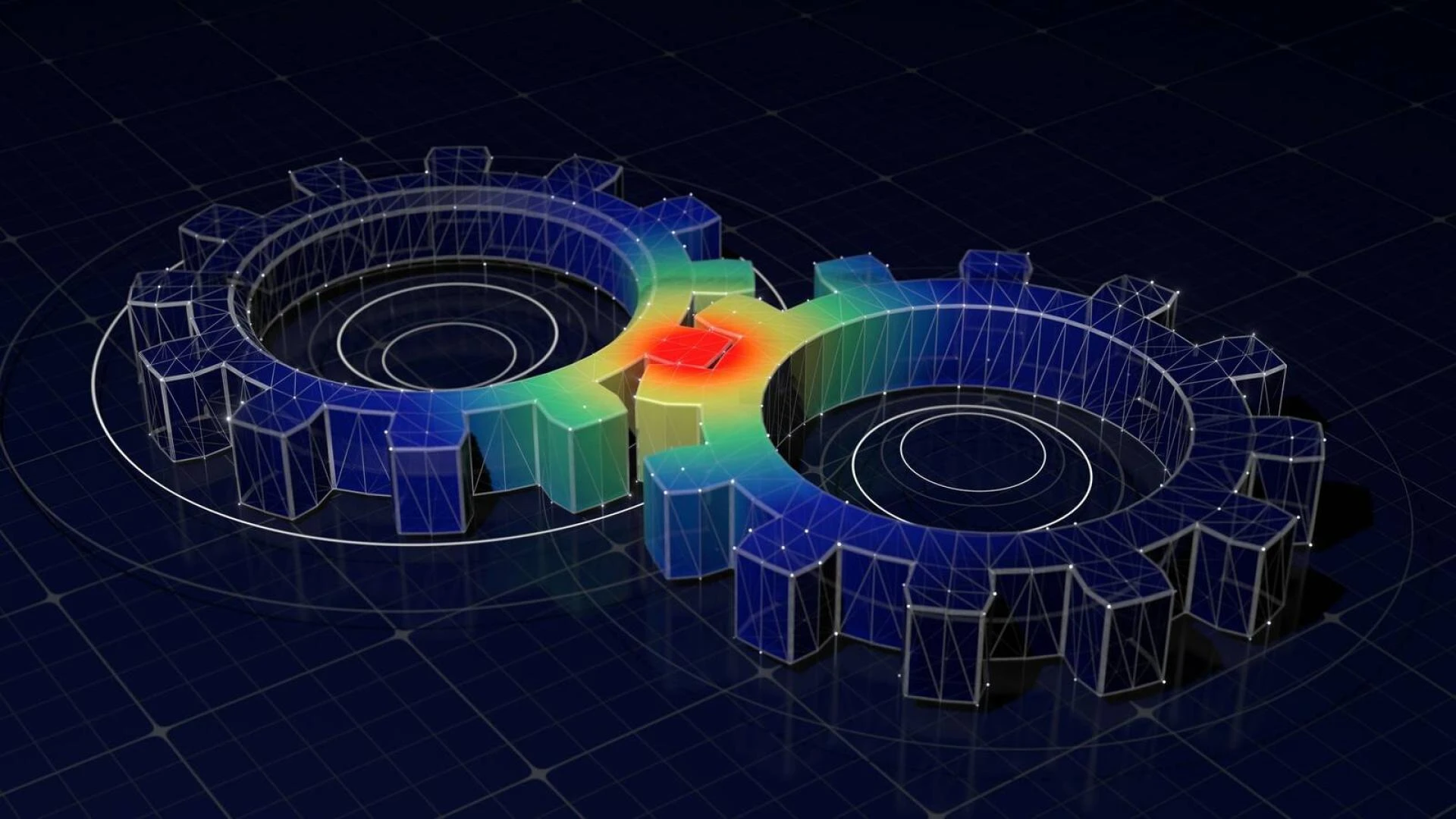

- Postprocessing: The results are visualized in the form of color-coded plots, graphs, and animations. Engineers can interpret these results to evaluate stresses, strains, displacements, temperatures, fluid velocities, and other important physical responses.

Key Applications of FEA Engineering

FEA is widely used in many fields for design validation, optimization, and failure prediction. Some important applications include:

1. Structural Analysis

In civil and mechanical engineering, FEA is used to analyze how buildings, bridges, vehicles, and machinery respond to loads, vibrations, impacts, and environmental effects. Engineers can identify potential weak points and improve designs for strength and durability.

2. Thermal Analysis

FEA allows simulation of heat transfer within components. This is crucial in industries like electronics (to prevent overheating of chips) and aerospace (for thermal protection systems in spacecraft).

3. Fluid Dynamics

When integrated with Computational Fluid Dynamics (CFD), FEA helps study fluid flow around and inside objects — for example, analyzing air resistance on cars or blood flow in medical devices.

4. Crash and Impact Analysis

Automobile manufacturers use FEA extensively to simulate crash tests virtually, optimizing vehicle structures for better occupant safety without needing multiple physical prototypes.

5. Manufacturing and Process Simulations

FEA can simulate manufacturing processes such as casting, welding, metal forming, and additive manufacturing. It helps predict defects like warping, residual stresses, or cracks during production.

Benefits of FEA Engineering

1. Cost and Time Efficiency

FEA reduces the need for physical prototypes, saving significant costs and time. It allows companies to bring products to market faster and with more confidence in their performance.

2. Improved Product Performance

By identifying potential problems early in the design phase, engineers can refine products for greater reliability, safety, and efficiency.

3. Risk Reduction

FEA provides insights into worst-case scenarios and failure modes, enabling better risk management and compliance with industry safety standards.

4. Design Innovation

Virtual testing through FEA gives engineers the freedom to experiment with new materials, unconventional designs, and complex structures that would be too costly to test physically.

Challenges and Limitations

While FEA offers tremendous advantages, it is not without challenges:

- Accuracy Depends on Model Quality: Simplifications, poor meshing, or incorrect boundary conditions can lead to inaccurate results.

- High Computational Requirements: Large, detailed models can demand substantial computing power and time.

- Requires Skilled Engineers: Proper interpretation of results and setting up accurate simulations requires expertise and experience.

- Not a Replacement for Physical Testing: Though powerful, FEA should complement, not entirely replace, experimental validation.

The Future of FEA Engineering

The field of FEA is rapidly evolving alongside technological advancements. Here are some trends shaping its future:

1. Integration with AI and Machine Learning

Artificial intelligence is starting to enhance FEA by optimizing mesh generation, suggesting boundary conditions, and predicting simulation outcomes faster. Machine learning models trained on FEA datasets can also accelerate design processes.

2. Cloud-Based FEA Solutions

Cloud computing allows large simulations to be run faster and more cost-effectively without needing high-end local hardware. Cloud platforms also enable collaboration across global engineering teams.

3. Multiphysics Simulations

Modern products increasingly require consideration of multiple interacting physical phenomena (e.g., thermal, structural, and fluid behaviors simultaneously). Advanced FEA tools are moving toward integrated multiphysics capabilities.

4. Real-Time Simulation and Digital Twins

Combining FEA with sensors and IoT devices enables the creation of digital twins—virtual replicas of real-world assets that update in real-time. This allows for ongoing monitoring, predictive maintenance, and performance optimization.

Conclusion

FEA Engineering has revolutionized how industries design, test, and improve products and systems. It enables deeper insights, better performance, lower costs, and faster innovation. As FEA technology continues to advance with AI, cloud computing, and real-time analytics, its impact will only grow, offering even more powerful tools for engineers of the future.

For engineers and companies alike, staying up to date with the latest FEA trends and best practices is essential to maintaining a competitive edge in an increasingly complex and demanding world.