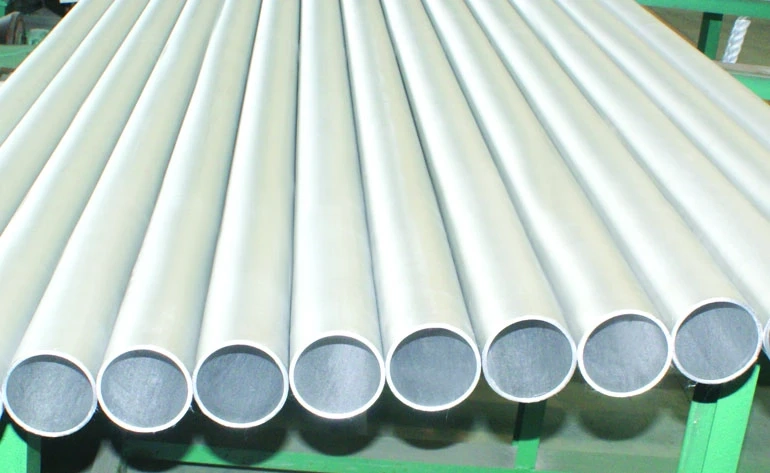

Stainless Steel 446 is a ferritic stainless steel that contains chromium as the main alloying element. It is a high-temperature resistant alloy commonly used in applications requiring heat and corrosion resistance. Stainless Steel 446 Pipes are made from this material and used in a wide range of industrial applications. These pipes exhibit excellent corrosion resistance and high-temperature strength, making them popular in various industries such as chemical processing, power generation, and food processing. Stainless Steel 446 pipes are ideal for high-temperature applications due to their unique properties, which make them resistant to scaling and oxidation.

Applications of Stainless Steel 446 Pipes

Chemical Processing: The pipes are widely used in chemical processing industries due to their corrosion resistance properties. They are used in the transportation of corrosive chemicals and acids.Oil and Gas Industry: The pipes are also used in the oil and gas industry for high-temperature applications. They are used in pipelines to transport crude oil, natural gas, and other hydrocarbons.Power Generation: The pipes are used in power generation industries for applications such as heat exchangers, boiler tubes, and steam generators. They are suitable for high-temperature applications due to their excellent resistance to scaling and oxidation.Food Processing: Stainless Steel 446 pipes are used in food processing industries where hygiene and sanitation are critical. They are ideal for applications where the pipes come into contact with food and beverages.Aerospace Industry: The pipes are used in the aerospace industry for applications such as exhaust systems and turbine components. They can withstand high-temperature environments and are resistant to scaling and oxidation.Automotive Industry: The pipes are used in the automotive industry for exhaust systems and catalytic converters. They are suitable for high-temperature applications and can withstand exposure to corrosive gases and chemicals.Benefits of Stainless Steel 446 Pipes

High-temperature resistance: Stainless Steel 446 pipes have excellent high-temperature strength and can withstand temperatures up to 1200°C.Corrosion resistance: These pipes have good resistance to corrosion in various environments, including acidic and alkaline solutions.Oxidation resistance: Stainless Steel 446 pipes are highly resistant to scaling and oxidation at high temperatures.Ductility: These pipes have good elasticity and can easily form into various shapes.Durability: Stainless Steel 446 pipes are durable and have a long lifespan, reducing the need for frequent replacements.Cost-effective: These pipes are relatively cost-effective compared to other high-temperature-resistant alloys.Low maintenance: Stainless Steel 446 pipes require minimal maintenance due to their corrosion and oxidation resistance properties.Versatility: These pipes can be used in various applications due to their unique properties.Hygiene: Stainless Steel 446 pipes are suitable for use in applications that require hygiene and sanitation, such as the food and beverage industry.Eco-friendly: These pipes are recyclable and environmentally friendly, reducing the environmental impact of industrial processes.