Demisting involves the separation or elimination of mist or liquid droplets from gas or vapor streams. The use of a vane mister eliminator leads to decreased contamination and product losses, lower emissions, and improved separation efficiency.

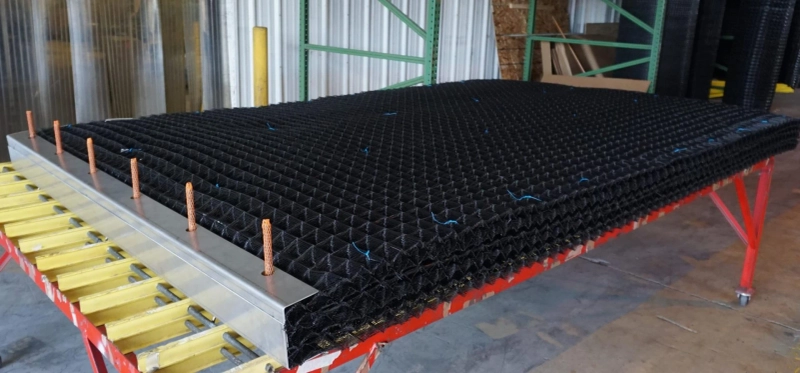

Mist eliminators are also commonly referred to as mesh pads. They are made predominantly from stainless-steel alloys and various mesh materials that catch the liquid particles as they flow through the machine in a gas stream. Mesh pads can collect liquid droplets are small as 3-5 microns in diameter, but they have limited liquid handling capabilities. For this reason, chevrons are used in many mist eliminators. Chevrons can handle high volumes of liquids but used independently have limited liquid collection efficiencies and are susceptible to contamination.

Effects of the Pandemic on the Market

The recent pandemic has seen a dip in the vane mist eliminator markets. Mainly, this is due to changes in people’s energy consumption and disruptions or suspensions in the manufacturing and supply processes worldwide.

However, with increased environmental regulations and growing demand for high-quality most eliminators within several end-use industries, this market is likely to start growing once again.

Growth of the Market

Market research on the vane mist eliminator predicts future product growth, with interesting new opportunities and challenges present each year as the industry develops. Industries that require products like the mesh pad mist eliminator include oil and gas, power, food and beverage, paper, and more. The oil and gas industry is expected to account for most of the global mist eliminators market share.

The global mist eliminator market is projected to grow to 1000 159 million in the next 4-5 years at a CAGR of 4%. The increased demand for mist eliminators is predominantly due to the increasingly stringent environmental regulations aiming to reduce their emissions. Alongside this, the increased consumer demand for oil and gas, chemical, and power industries are driving the growth of the mist eliminator.

Use Within the Oil and Gas Industry

The latest research shows in-depth profiling and a well-rounded overview of products and services within the industry. Regulation analyses looked at regional variations in the laws surrounding the use of vane mist eliminators, their implications, and other compliances. In particular, mesh-wire and vane mist eliminators show promising increases in demand within the oil and gas and chemical industries owing to suitability to process conditions and ease of repair and maintenance. Mist eliminators are beneficial for use in distillation towers that process crude oil to produce high purity products. They offer a cost-effective way to enhance performance and efficiency.

For more information on our high-quality vane mist eliminator and mesh pad mist eliminator products, contact the team at Kimre today.