Chemical injection pumps are designed to improve well production, pipeline flow, and reduce corrosion. They operate under specific chemical and fluid requirements depending on the temperature and pressure with which the injection pump will be working at. Ultimately, chemical injection pumps deliver specific chemicals to the production system at determined rates. These procedures are required for the safe application of chemicals and for oilfield systems to work efficiently. Chemical Injection Pumps are common systems within the Canadian oil and gas industry. Some of the chemicals used include solvents, de-salting agents, corrosion inhibitors, biocides, clarifiers, scale inhibitors, hydrate inhibitors, oxygen scavengers, surfactants, and more. Sometimes methanol is used to reduce freezing which causes pipelines to clog. This can be a complex subject, but it is important to understand the different applications, limitations, and conditions that contribute to the efficiency of these systems and their overall performance.

Chemical Injection Pumps - Morgan Chemical Metering Pumps

High Pressure Technologies provides Morgan’s Pneumatic Chemical Metering Pumps which are widely used in the oil & gas industry. High pressure chemical injection pumps are used to inject chemicals such as corrosion inhibitors, defoamer or anti-foamers, detergents, methanol, and emulsifiers or de-emulsifiers into your pipeline for the specific application. Where your application is keeping a pipeline flowing, improving well production, or neutralizing corrosive substances you need a high-quality, reliable chemical metering pump.

Each type of chemical injection pump comprises intricate features that are designed to provide specific benefits to the customer and his application.

Morgan’s pneumatic metering chemical injection pumps are economical performers. Morgan builds precision pumps with vast applications in oil, gas and water treatments. Over 20 years of experience supports the design and manufacture of pumps that, on occasion, have raised the entire industry’s standards. Morgan chemical injection pumps for oil and gas are designed for lasting performance and easy maintenance. The quality of Morgan products is continually acclaimed in the field for accurate performance, minimal maintenance, and long life.

High-Pressure Technologies also provides complete Chemical Injection Skids.

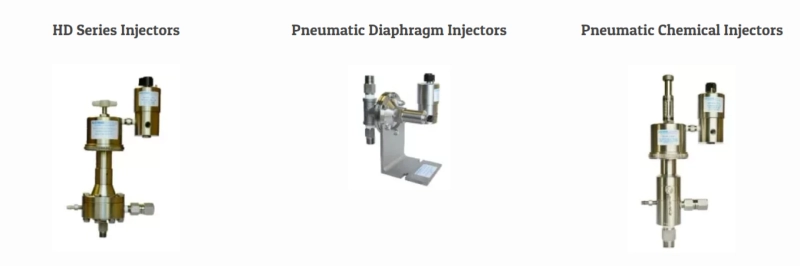

HD Series Chemical Injection Pumps

These pumps are manufactured utilizing a hydraulic design, which incorporates hydraulic seals. The seals prevent any leakage of chemicals during operation in an application. The beneficial features of HD series injectors comprise:

A Teflon coating is applied to the diaphragm to prevent corrosion.

The pump’s overhead chamber consists of oil, which is used as a plunger lubricant as well as hydraulic fluid.

A combination coating of Teflon and Inconel is applied to the plunger spring to ensure longer service life.

The pump housing is constructed from stainless steel, making it extremely reliable in corrosive environments.

Pneumatic Diaphragm Chemical Injection Pumps

These injectors are designed to provide strength and durability in an application. Morgan has achieved this by constructing chemical injection pumps in stainless steel. Morgan also provides diaphragm injectors in a PVC and stainless steel combination to achieve high corrosion resistance capabilities. The beneficial features of pneumatic diaphragm injectors include:

A Teflon-laminated diaphragm along with the stainless steel construction provides enhanced product durability.

Ideal for applications involving corrosive acids with pressures up to 150 PSI.

The pump’s design eliminates unbalanced pressure that can lead to diaphragm failure.

Fluid rate and volume can be adjusted while the pump in is operation.

Stainless steel base allows for secure pump installation.

Pneumatic Chemical Injection Pumps

This pump type is ideally suited for corrosive applications involving volatile chemicals like methanol. The plunger within the pump is constructed out of 17-4 PH stainless steel. The pump is also provided with a protective coating of titanium nitride. This protects the chemical injection pump from extreme abrasions, thus providing a longer service life. Following are the beneficial features of pneumatic chemical injector pump:

The plunger and seal can be easily accessed due to a hand-tightened lock ring.

A combination coating of Teflon and Inconel is applied to the spring to ensure longer service life.

The plunger is independent of the air piston, allowing for separate replacement, which reduces maintenance costs.

Chemical injection systems are a vital part of the oil and natural gas production. Chemical injection is the IV that keeps the product flowing from the wellhead through downstream, midstream, and upstream processes. Chemical injection introduces the necessary chemicals required to maintain the integrity of the piping, tubing, instrumentation, valving, and pumps in the flow line processes. Chemical injection introduces the necessary chemical required to maintain smooth, continuous flow through the pipeline process system.

Design of chemical injection pump

In designing a chemical injection pump, it is necessary to pay attention to several important issues in order for the device to have proper efficiency and longevity. The most important points in dosing pump design are the following options:

The material used for components that come in contact with chemicals must be corrosion resistant. For example, for the wet part (parts related to chemicals), propylene, PVC and PVDF can be used.

Material flow rate and injection pressure should be adjustable according to the type of material and fluid conditions such as pH, etc. Dosing pumps often have the possibility of adjusting the flow mechanically and in some cases the required settings can be done manually.

Another very important factor in the design of a metering pump is the accuracy of the pump components. It should be noted that the components of pumps vary according to their type. As used in piston pumps, crankshaft, seal, outlet valve, inlet valve, piston and cylinder, and in the type of diaphragm, chamber, diaphragm, inlet and outlet valves, crankshaft and plunger. Accuracy in the quality of each of these parts and components has a direct impact on the life of the device and greatly increases efficiency.

The heart of the chemical injection system is the chemical metering pump. Typical pumps are available in AC, DC (solar), and pneumatic. Sidewinder manufactures all 3 pumping systems, available with many end options for chemical compatibility.

0