What is a CNC lathe machine?

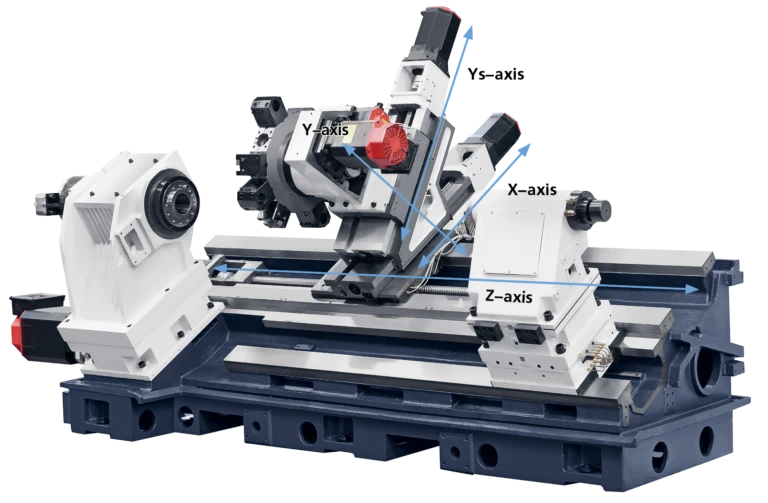

A CNC lathe machine is a machine where the material or part is held in place and rotated by the main spindle as the cutting tool that works on the material is mounted and moved on various axes.

A simple CNC lathe operates on two axes with the cutting tool in a fixed position at 8 to 24 station turret. There are numerous benefits of using a CNC lathe such as a highly powerful axis drive, feedback control to monitor and maintain the tool position, higher speed, repetitive movement of complicated machines, etc.

But the benefits of a CNC lathe machine don\'t end there; below, discover a few further advantages of using this kind of device.

Advantages of CNC lathe machine

- Easy to operate

CNC lathes are simple to set and easy to operate. They primarily help to implement the innovative methods of manufacturing, in order to obtain the maximum benefit of the latest technology.

The machine components are preset and the tool paths are pre-planned by the CAD and CAM processes. The programmed file is then tested and loaded on the machine.

The operator thereafter issues the related commands to activate the necessary parts of the machine. It doesn\'t require much skill.

- Bestow the option of customization

A lathe permits for the precise customization of your project. The deliverables are built according to your specs, no matter how perplexing the project might be.

The speed and dependability of lathe machining means that the machine shop can deliver small or large lots based upon your needs and requirements.

And you can always count on high-quality finished products made with the precision outlined in the specs.

- Make the process time and money efficient

Using CNC lathe machines will make the process of manufacturing both time consuming and cost-efficient.

You save both money and time by having a machinist handle your metal lathe project. Fewer operators are required with CNC metalwork that too with no higher skills, so there are often lower labor costs than with more traditional manual lathes.

As machines are made for perfection there is no chance of any error in the final product or waste in the material.

Because of the high degree of accuracy involved in this method, there is less human error and less material waste, another financial benefit.

And work can typically be performed in a fraction of the time, which is essential for deadline-sensitive projects.

- Enables repeatability and turning

These machines let the machinist perform repeated functions without compromising accuracy, which is especially crucial for large lots. Also, CNC methods make it easy to modify the programmed information as needed throughout the course of production.

This is one of the prominent reasons for the wide acceptance and utility of these machines.

Summary

Let’s conclude the advantages of CNC lathe machine.

- The accuracy is very high in the case of CNC lathes compared to normal Machining lathes.

- The flow of production is more

- It requires a few operators in a manual lathe.

- The machining in the lathe and CNC lathe was very fast

- The lead time will be very less