A fixture is a production tool that is used to locate and hold one or more pieces of work so that the necessary operations can be performed. A fixture must be firmly in place.

Attached to the machine table Since fixtures are mostly used on milling machines, they need to be designed to be suitable for different operations. Main purpose

The use of fixtures is to determine the location of the workpiece quickly and correctly, and to hold it well and firmly.

Considering the number of products manufactured as fixture retaining parts help simplify metal operations with special tools on all standard machines. In the following many cases of

Operations that may require fixtures are written:

Assembly , bending, internal drilling, polishing, polishing, stonework, polishing of holes, polishing and polishing of bearings and bearings, milling, gratering, profile preparation

A mold or other part by milling machine, electrician, rivet, saw, blacksmith, smoothing rough or cast surfaces, joinery, testing, turning, welding.

Pars Sanat Company has a brilliant history in the field of production of fixtures and jigs, and experienced engineers are ready to provide advice, design and manufacture of various fixtures and jigs.

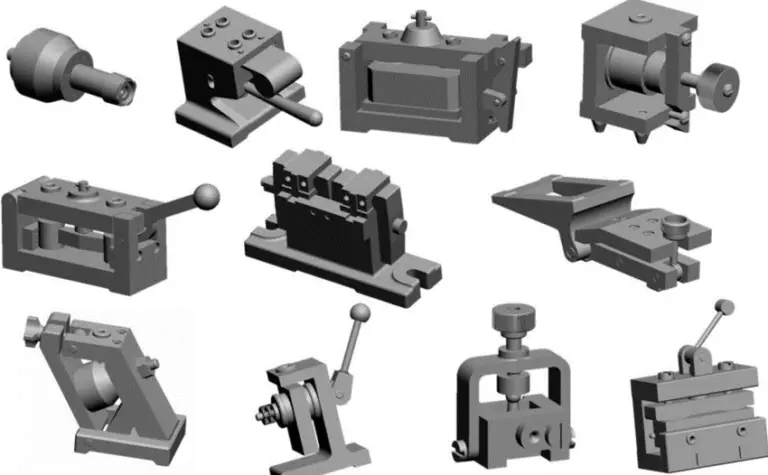

Types of fixtures:

The types of fixtures are determined based on the method of their construction. Common types of fixtures are: plate fixtures, angular fixtures, rotating fixtures,

Multi-station fixtures and clamps. Screen fixtures are the simplest type of fixture. The main part of this fixture is a base plate that has different parts such as

Mounting and retaining pins are mounted on it.

Vertical angle fixture is a modified version of the plate fixture. Using this tool, the workpiece can be machined on surfaces perpendicular to its surface. Of course you can

This fixture is designed in such a way that the parts can be machined at any desired angle.

Rotary fixtures are used when machining positions need to be placed on the workpiece at regular intervals around it.

Multi-station fixtures are used when a high production number and production speed are required and the machining cycle is continuous.

Clamps are the most common type of fixture. Clamps are actually a simple fixture to hold the parts. By modifying the shape of the clamp jaws, it can be held to hold

Used parts with different shapes.

Clamp-mountable fixtures These types of plate fixtures are usually small, simple and lightweight. These fixtures are mounted on clamps or three instead of directly on the machine

The machine system is restrained. Small parts that require little machining are usually fastened to these fixtures. Plate fixtures and fixtures that are mounted on clamps

source: https://farco-psr.com/what-is-a-fixture-and-what-are-its-types/

0

0