Slip rings are essential components used in various mechanical and electrical systems to transmit power, electrical signals, and data between rotating and stationary parts. They find applications in a wide range of industries, including robotics, wind turbines, medical equipment, and industrial machinery. In this comprehensive article, we will delve into the intricacies of slip rings, exploring how to use a slip ring and their functionality, applications, and the best practices for using them effectively.

What are Slip Rings?

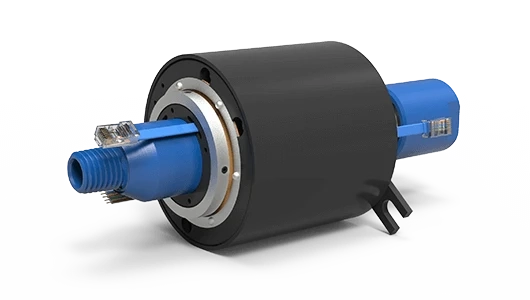

Slip rings, also known as rotary electrical interfaces or electrical swivels, are electromechanical devices used to transfer electrical power and signals from a stationary structure to a rotating one. They provide a reliable connection between the stationary and rotating parts, allowing continuous transmission of electricity and data without the interference caused by traditional wire connections.

How Do Slip Rings Work?

A slip ring consists of two main components: the rotor and the stator. The rotor is mounted on the rotating part of the system, while the stator is fixed to the stationary structure. Inside the slip ring, multiple conductive rings and brushes are arranged in a circular pattern. When the system rotates, the brushes maintain contact with the rings, establishing an electrical pathway for power and signals.

Types of Slip Rings

Conventional Slip Rings

Conventional slip rings are the most common type and are suitable for a wide range of applications. They feature a compact design and can transmit both power and signals reliably. Conventional slip rings are available in various configurations, including single-channel, multi-channel, and hybrid designs.

Capsule Slip Rings

Capsule slip rings are compact and lightweight, making them ideal for space-constrained applications. They are often used in robotics, cameras, and small machinery. Despite their small size, capsule slip rings can transmit power, Ethernet, USB, and other signals simultaneously.

Through-Bore Slip Rings

Through-bore slip rings are designed with a hollow center, allowing the passage of fluids, gases, or other rotating components. They are commonly used in applications that require the integration of rotating fluid or pneumatic connections, such as rotary joints used in hydraulic systems.

Importance of Slip Rings in Industrial Applications

Slip rings play a crucial role in various industrial applications, enabling the seamless transfer of power and signals in rotating systems. By utilizing slip rings, industries can achieve continuous rotation without the hassle of tangled cables or limited range of motion. This promotes efficiency, reliability, and safety in demanding environments.

Common Uses of Slip Rings

Robotics

In the field of robotics, slip rings facilitate the transmission of power and data between the stationary base and the rotating joints. This allows robotic arms and other automated systems to move freely without cable constraints, enabling precise movements and improving overall performance.

Wind Turbines

Wind turbines rely on slip rings to transfer power generated by the spinning blades to the stationary components of the turbine. Slip rings enable the connection between the generator and the electrical grid, ensuring efficient power transmission and contributing to the production of clean energy.

Medical Equipment

Slip rings find extensive usage in medical equipment, particularly in imaging devices such as CT scanners and MRI machines. They enable the transmission of power and signals between the rotating gantry and the stationary imaging system, allowing for precise and high-quality medical imaging.

CCTV Systems

Closed-circuit television (CCTV) systems often incorporate pan-tilt-zoom (PTZ) cameras that require continuous rotation for effective surveillance. Slip rings enable the rotation of the camera while maintaining uninterrupted power supply and video transmission, ensuring comprehensive monitoring capabilities.

Radar Systems

Radar systems heavily rely on slip rings to rotate the antenna array, enabling the scanning of the surrounding environment. Slip ring allows the continuous transmission of power and signals, ensuring accurate detection and tracking of objects, vital for military, weather, and aviation applications.

Conclusion

In conclusion, slip rings play a vital role in enabling the seamless transmission of power and signals between rotating and stationary parts in various industries. Understanding the functionality, types, and proper usage of slip rings is crucial for achieving optimal performance and reliability in mechanical and electrical systems. By considering the specific requirements of your application, you can select the right slip ring and follow recommended installation and maintenance practices to ensure long-term functionality and efficiency.