What is Kovar?

Nickel, iron, and cobalt alloy Kovar has qualities that allow for regulated thermal expansion. In hermetic sealing applications, it is frequently employed. It is durable, adaptable, and has a thermal expansion coefficient that is comparable to that of hard glass. To guarantee homogeneity in the physical qualities, Kovar alloy is produced under strict quality controls.

Intense pressure can be produced when two connected materials expand and compress at different speeds.In daily life, you'll likely pass by kovar, an alloy that expands and contracts at the same pace as borosilicate glass, without giving it a second thought.The longevity of commonplace components like x-ray tubes and power tubes depends on Kovar.Major advantages of Kovar

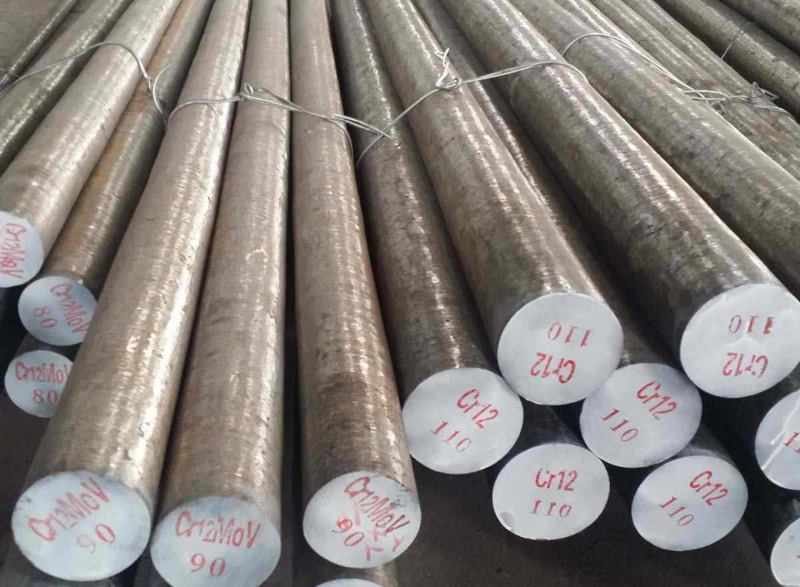

The most significant mechanical characteristic of Kovar Bar is its coefficient of thermal expansion. The alloy is carefully designed and managed to generate a coefficient of thermal expansion that is extremely similar to that of ceramic or hard glass (such as borosilicate glass), meaning that it expands and contracts at a comparable pace. As a result, it works perfectly in applications where glass or ceramic materials are involved, particularly where a hermetic seal needs to be maintained across a wide temperature range. Metal and glass or ceramic are combined to make a sizable range of goods. There are certainly numerous examples of such products in everyday life.

Common uses of Kovar

The most significant mechanical characteristic of Kovar is its coefficient of thermal expansion. The alloy is carefully designed and managed to generate a coefficient of thermal expansion that is extremely similar to that of ceramic or hard glass (such as borosilicate glass), meaning that it expands and contracts at a comparable pace. As a result, it works perfectly in applications where glass or ceramic materials are involved, particularly where a hermetic seal needs to be maintained across a wide temperature range. Metal and glass or ceramic are combined to make a sizable range of goods. There are certainly numerous examples of such products in everyday life.

We can then examine how Kovar functions in actual scenarios if we use a classic tube light as an example, which is widespread in many workplaces. Having accidently touched a tube lightbulb, we are all aware of how quickly the glass may get incredibly hot. Electricity generates a tremendous amount of heat, which quickly transfers to the glass in order to produce the necessary lighting.

It would be highly risky and practically impossible to attach the glass tubing to the metal holds using metals other than Kovar. This is so that each element—glass and traditional metals—would expand and contract at a distinct rate due to the fact that the thermal expansion coefficient of traditional metals is substantially different from that of hard glass. This would inevitably result in more pressure being placed on the glass tube, which would either break under the increasing pressure or be unable to maintain its hermetic seal.

Other items that require a glass to metal (or ceramic) seal, such as microwave tubes, transistors, diodes, power tubes, and x-ray tubes, also employ kovar. Additionally, it has been utilised in integrated circuits, including the dual-in-line package and flat pack.

When you consider the amount of glass to metal seals needed in common products, you will realise just how vital Kovar is even though it may not be the most well-known alloy you will ever come across.