Beam Trolleys form a significant part of overhead conveyors that are easy and convenient to use, plan and install. They are available in different size, capacity, prices, dimensions and structure with their own monorail system requirements in different industries like- factories, paint finishing lines, workshop requirements and other automotive assembling arrangements. Along with that, beam trolleys contribute significantly in transferring the products from one place to the other with the utmost smoothness and consistency. You just need to attach the product properly with the trolley using a hook and push the same to move the products in case of push-pull beam trolley and pull the chain in case of geared bean trolley. You can read more about the functionalities of beam trolleys and their usage.

Features and functions of beam trolleys

It has been observed that beam trolleys come in differentiated operating style, curves, and straights that facilitate easy travelling and holding. Along with that, it comes with a long-lasting functional type that requires minimum effort while conducting any travelling operations. Moreover, it possesses the capability to reduce the frictional effect and simultaneously disseminate the load upon all the four adhered wheels so as to simplify the process. It forms an integral part of the Travelling Trolley system that smoothen the operations of assembly with minimum downtime effects. Search online about the same to collect more information before purchase.

The performance and operations of Motorized Trolley

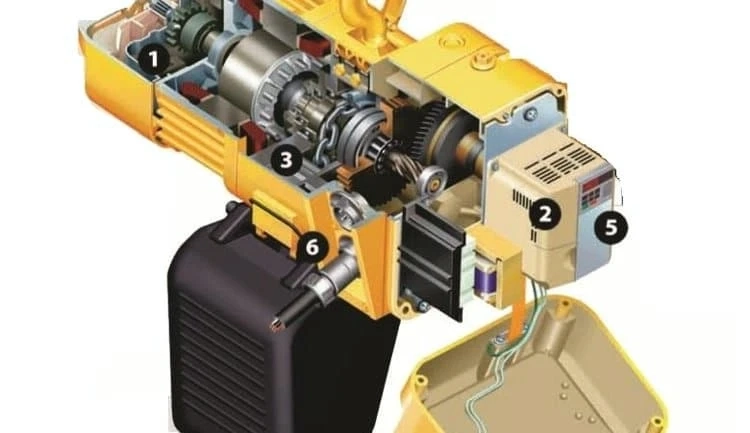

When it comes to Motorized Trolley, it comprises of extended lifting capacities that are applicable to multiple applications. Moreover, it comes with a user-friendly format that delivers commendable performance with a reduced level of risk and uncertainty. It possesses the capacity to withstand even in any harsh conditions and can apply the brake to the motor while handling any unit. Simultaneously, it ensures smooth and consistent operations with a significant capacity range to perform all the procedures efficiently. It requires contractor control or standard frequency inverter for both single-speed operation and dual-speed operation, respectively. Look for the best prices with comparable options to purchase the same in a bulk quantity for better connectivity.

Best process of conducting operations with a Motorized Trolley

Motorized trolleys are easy to adjust and convenient to fit into the beam flange width and come with a stabilizing shaft as well. Moreover, it does not require much more of the maintenance and can be smoothly rotated without any involvement of the frictional unit. It is easy to hold and ensures reliability in conducting operations to a greater extent. Further, it is attached with the wheels that are heated and hardened well so that it delivers consistent performance without much breakage. It will ensure a trouble-free life and comes with a compatible design at its best. It looks for a uniform distribution of weights that maintain strength and power at every level. It can equally minimize the traversing distances with a precision of seal and ball bearing at the helm. You can also look for an electrical chain hoist for simplified motion.

You can connect with LOADMATE to purchase Overhead cranes, EOT Crane, Electric Chain Hoists, Jib Crane, Under Slung Cranes and other overhead lifting equipment to increase the productivity in lifting and shifting.