It should go without saying that the performance potential of your technology can only be fully realized through good product design. It makes Laser design consulting possible to produce goods that are lightweight, durable, easy to use, dependable, and affordable to produce.

Product development that is as efficient as possible: A carefully thought-out Picosecond seed source design will maximize the efficiency of the product development process. An expedited development process results in earlier income and earlier creation of market position. When Diode pumped laser costs are taken into consideration, these factors are important but sometimes overlooked. Utilize designs with improved fabrication tolerances or designs with fewer parts to lessen manufacturing difficulties.

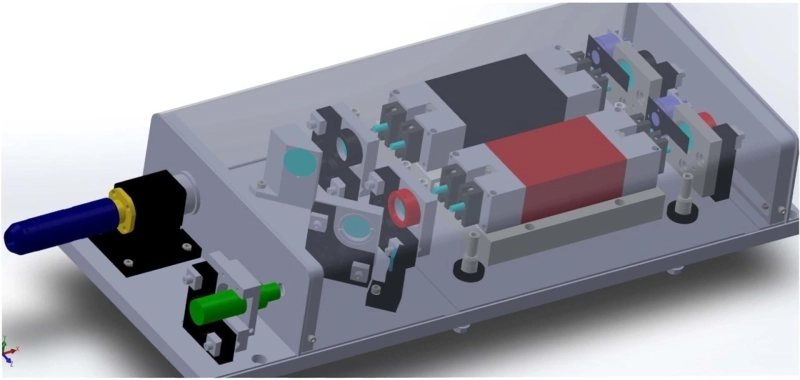

The Role of laser system Design in the Development Process

A Component of laser system design is typically thought of as a written document that summarizes the lessons learned at the end of the development phase. The problem with that approach is that there is too much "trial and error" and the development process could not have a solid enough basis as a result. Since they usually have undesirable side effects, problems are frequently difficult to assess in the lab and are even more difficult to solve with design changes at this point. The thorough design document must be developed before the prototype is built and tested. The goal of any design process that takes place at a desk must be to identify and resolve any possible difficulties that may occur because design adjustments may be performed here quickly and inexpensively.

There are several benefits to a well-organized development process, including:

Overall effort and cost are reduced because meticulous preparation at the desk saves money and time compared to iterations in the lab.The final product design most likely offers better dependability, performance, and manufacturing ease.The challenges are thoroughly understood, which is helpful for forthcoming projects.The team's competence is reinforced and you become less reliant on the lone skill of individual employees because the outcomes are meticulously documented and discussed within the team.