Open cell foam delivers exceptional value to homeowners by providing multiple benefits in a single application while requiring less material than traditional insulation methods. This versatile insulation solution combines thermal performance, air sealing, and sound dampening capabilities at lower material density, making it efficient for large residential spaces. The foam expands significantly during application, covering more area per unit of raw material compared to other insulation types.

Homeowners benefit from open cell foam's ability to fill irregular spaces completely, eliminating gaps that reduce insulation effectiveness and require additional sealing work. The material's lower density means faster installation with less product needed to achieve proper R-values, while its air sealing properties eliminate the need for separate vapor barriers in many applications. This combination of features reduces both material usage and labor requirements.

Installation Efficiency Advantages

Rapid Application Process

Open cell foam installs quickly due to its fast expansion rate and ease of application. Spray foam insulation professionals can cover large areas efficiently, reducing labor time compared to traditional batt or blown-in insulation methods. The foam's ability to fill complex spaces around utilities and structural elements eliminates time-consuming cutting and fitting required with rigid insulation materials.

Single-Step Air Sealing

Open cell foam provides thermal insulation and air sealing simultaneously, eliminating the need for separate air sealing products and labor. This integrated approach reduces installation steps while ensuring comprehensive coverage of air leakage pathways. Traditional insulation methods require additional caulking, weatherstripping, and vapor barrier installation that adds time and material requirements.

Bonus Tip: Schedule open cell foam installation during moderate weather conditions (60-80°F) to optimize expansion rates and minimize material waste.

Minimal Surface Preparation

Open cell foam adheres to most building surfaces without extensive preparation, reducing pre-installation labor requirements. The foam conforms to irregular surfaces and fills gaps automatically, eliminating the precise fitting needed with rigid insulation boards. This adaptability saves preparation time while ensuring complete coverage.

Material Efficiency Benefits

Open cell foam's low density means homeowners get more coverage per pound of material compared to denser insulation types. The foam expands 60-100 times its liquid volume, providing extensive coverage from relatively small amounts of raw material. This expansion efficiency translates to lower material transportation and storage requirements.

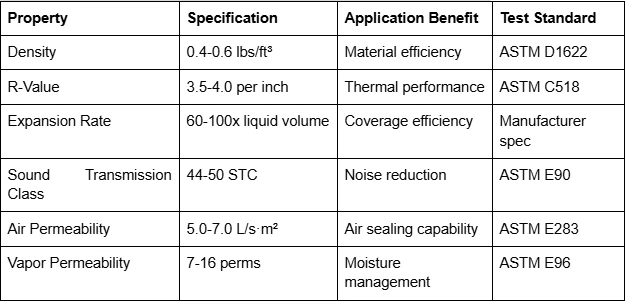

Open Cell Foam Performance Specifications

Cost-Effectiveness Comparison

Energy Efficiency Value

Heating and Cooling Load Reduction

Open cell foam reduces energy consumption by eliminating air leakage that forces HVAC systems to work harder maintaining comfortable temperatures. The foam's air sealing properties prevent conditioned air loss and unconditioned air infiltration. This reduction in heating and cooling loads translates to lower utility bills throughout the home's operational life.

Consistent Temperature Control

The foam creates uniform thermal barriers that eliminate hot and cold spots common with traditional insulation methods. Consistent temperatures throughout the home improve comfort while reducing the need for supplemental heating or cooling in problem areas. This uniformity allows HVAC systems to operate more efficiently.

Bonus Tip: Combine open cell foam installation with programmable thermostats to maximize energy savings through optimized temperature control.

HVAC System Efficiency

Properly sealed homes with open cell foam insulation allow HVAC systems to operate at designed efficiency levels. Reduced air leakage means heating and cooling equipment cycles less frequently while maintaining desired temperatures. This improved efficiency extends equipment life while reducing maintenance requirements.

Acoustic Performance Benefits

Sound Absorption Properties

Open cell foam's structure provides excellent sound absorption, reducing noise transmission between rooms and from outside sources. The foam's acoustic properties eliminate the need for separate soundproofing materials in many applications. This dual functionality provides additional value beyond thermal performance.

Vibration Dampening

The foam reduces structural vibration transmission that carries sound through building assemblies. This dampening effect improves overall acoustic comfort while protecting against noise-related comfort issues. Open cell foam's flexibility allows it to absorb vibrations that rigid materials cannot address.

Multi-Zone Noise Control

Open cell foam installation in walls, floors, and ceilings creates comprehensive noise control throughout the home. This whole-house approach to acoustic comfort provides better results than targeted soundproofing treatments. The integrated installation reduces overall acoustic treatment requirements.

Moisture Management Advantages

Vapor Permeability Benefits

Open cell foam allows controlled moisture vapor transmission, preventing condensation within building assemblies while permitting drying potential. This breathability reduces the risk of moisture-related problems compared to impermeable barriers. The foam's vapor permeability eliminates the need for complex vapor barrier systems in many climates.

Mold Prevention

The foam's air sealing properties prevent humid air infiltration that creates conditions for mold growth. By eliminating air movement through building assemblies, open cell foam reduces moisture transport that leads to condensation problems. This prevention protects both building materials and indoor air quality.

Drying Potential

Open cell foam installations allow building assemblies to dry toward the interior when moisture infiltration occurs. This drying capability prevents moisture accumulation that can lead to structural damage. The foam's permeability provides insurance against moisture problems from unexpected sources.

Application Versatility

Multiple Space Types

Open cell foam works effectively in attics, walls, crawl spaces, and basement applications. This versatility allows homeowners to use one insulation system throughout the home, simplifying material selection and contractor coordination. Consistent installation methods reduce complexity and potential installation errors.

Retrofit Applications

The foam's expansion properties make it ideal for retrofit applications where access is limited. Open cell foam can fill existing wall cavities through small injection holes, eliminating the need for extensive demolition. This retrofit capability provides upgrade options without major construction disruption.

Bonus Tip: Use open cell foam in basement rim joist areas where traditional insulation is difficult to install properly and air sealing is critical for comfort and efficiency.

Long-Term Performance Value

Dimensional Stability

Open cell foam maintains its shape and thermal properties over decades without settling or degrading. This stability ensures consistent performance throughout the home's life without requiring replacement or maintenance. The foam's flexibility accommodates building movement without creating gaps or thermal bridges.

Maintenance Requirements

Open cell foam requires minimal ongoing maintenance once properly installed. The material resists pest infiltration and does not provide nesting material for rodents or insects. This low-maintenance characteristic reduces long-term ownership requirements and associated expenses.

Things to Consider Before Making a Decision

Evaluate your home's specific insulation needs and climate requirements to determine if open cell foam matches your performance goals. Consider the building's age, construction type, and existing insulation levels when planning foam installation. Review local building codes and permit requirements for foam insulation applications.

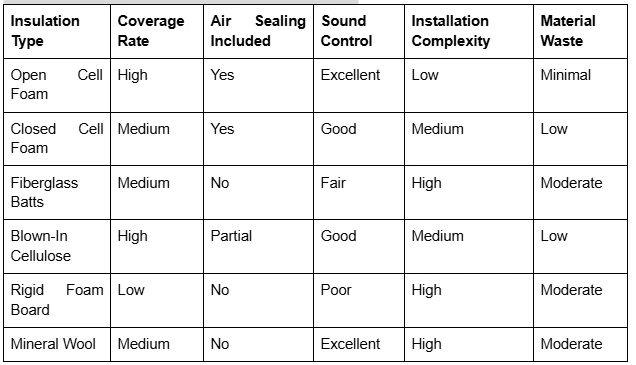

Assess your priorities regarding thermal performance, sound control, and air sealing to ensure open cell foam addresses your primary concerns. The foam excels in air sealing and acoustic applications but provides moderate thermal resistance per inch compared to closed cell alternatives. Consider your space constraints and R-value requirements when making material selections.

Plan installation timing to coordinate with other home improvement projects and weather conditions. Open cell foam requires proper temperature and humidity conditions during application for optimal performance. Factor in seasonal scheduling and contractor availability when planning your insulation project.

Common Questions About Open Cell Foam Value

Performance varies by application and installation quality - Properly installed open cell foam provides decades of consistent thermal and acoustic performance. Poor installation or inappropriate applications can reduce effectiveness and value significantly.

Climate suitability affects overall value proposition - Open cell foam works best in moderate climates where vapor permeability benefits outweigh thermal resistance limitations. Extreme cold climates may require additional considerations for optimal performance.

Professional installation ensures maximum value - Experienced installers optimize material usage and application techniques to maximize coverage and performance. DIY installation typically results in poor coverage and reduced effectiveness.

Why Open Cell Foam is a Cost-Effective Solution for Homeowners FAQ

How does open cell foam provide better value than traditional insulation methods? Open cell foam combines insulation, air sealing, and sound control in one application, eliminating the need for multiple products and installation steps. The foam's expansion properties provide extensive coverage from small amounts of material while filling gaps that traditional insulation cannot address effectively.

What makes open cell foam installation more efficient than other insulation types? Open cell foam installs quickly due to its rapid expansion and self-sealing properties, reducing labor time compared to traditional methods. The foam requires minimal surface preparation and eliminates cutting, fitting, and separate air sealing work required with batt or rigid insulation materials.

Can open cell foam reduce long-term home maintenance requirements? Open cell foam provides permanent air sealing and insulation that maintains effectiveness without settling or degrading over time. The material resists pest infiltration and moisture problems that affect traditional insulation, reducing replacement and maintenance needs throughout the home's operational life.

How does open cell foam improve home comfort beyond basic insulation? Open cell foam eliminates drafts and temperature variations that traditional insulation cannot address, creating more consistent comfort throughout the home. The foam's acoustic properties reduce noise transmission between rooms and from outside sources, improving overall living quality.

What applications provide the best value from open cell foam insulation? Attic spaces, interior walls requiring sound control, and retrofit applications provide excellent value from open cell foam's combined benefits. Areas with complex geometries around utilities and structural elements benefit most from the foam's gap-filling capabilities and comprehensive coverage.

Make the Right Decision

Choose open cell spray foam insulation service when your priorities include comprehensive air sealing, sound control, and efficient installation in moderate climates. The foam provides excellent value through its combined benefits and installation efficiency, particularly in applications where traditional insulation methods require multiple products and installation steps.

Work with experienced contractors who understand proper application techniques and material optimization. Verify installer certification and previous residential project experience to ensure you receive maximum value from your open cell foam investment through proper installation and performance.

Author and Reviewer: Author: Jeremy Fields brings over a decade of experience in construction and business to Ozark Eco Foam. With a background in both residential and commercial projects, he focuses on completing each insulation job with accuracy and attention to detail. Ozark Eco Foam reflects his commitment to quality work and practical solutions built on years of hands-on industry knowledge. Reviewer: Amelia Young contributed insights from 10 years in spray foam insulation. Her review helped sharpen the article's focus on customer engagement and clear service messaging.