The Aerospace Robotics Market is poised for significant growth, with a projected value of USD 4.9 Billion by 2026, demonstrating a compelling Compound Annual Growth Rate (CAGR) of 11.4% during the forecast period. This flourishing industry is a result of the surge in air passenger traffic, prompting a notable increase in aircraft orders from airlines worldwide. To meet stringent quality regulations and maintain efficient fleet production, aircraft manufacturers are increasingly turning to robots. This transformation is driven by the ability of robots to ensure error-free, high-quality production with unparalleled precision. In this blog, we delve into key drivers, restraints, opportunities, and challenges in the aerospace robotics sector.

Driver: Increase in Manual Labor Costs

Aircraft manufacturers strive to gain a competitive edge by offering lower-priced products, making labor cost management a critical concern. Robotics is expected to significantly reduce labor costs and enhance productivity. While initial robot acquisition costs are high, they prove cost-effective in the long run. Unlike human workers who require salaries, incentives, and allowances, robots require no such compensation, making them a compelling solution for the aerospace industry.

Get a Deeper Understanding of the Drone Analytics Market by visiting: https://www.marketsandmarkets.com/Market-Reports/aerospace-robotic-market-164758944.html

Restraints: Lack of Skilled Operators

The rapid evolution of aerospace robotics has surged the demand for robots, with the global supply doubling from 159,000 in 2012 to 294,000 in 2016. This number is projected to continue growing at an average rate of 12% per year from 2020 to 2022. However, this growth is hindered by a need for more skilled operators proficient in handling complex robotics systems. The complexity of robot operation, maintenance, and software management presents a significant barrier for manufacturers looking to embrace robotics in their production processes fully.

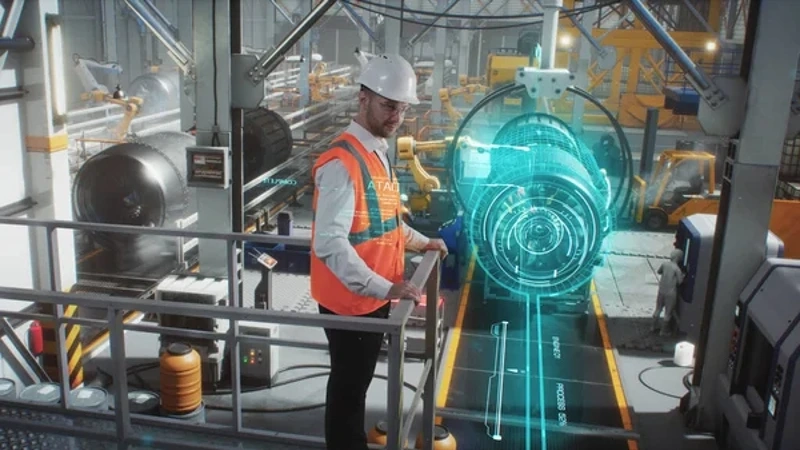

Opportunities: Human-Robot Collaboration

Robots are now replacing traditional production methods and working alongside human employees, boosting productivity and efficiency. The integration of robots and human workers has opened new possibilities for both. Some tasks are best suited for humans, while others excel when performed by robots. This collaborative approach in aircraft manufacturing taps into the strengths of both humans and robots, fostering improved production processes.

Challenges: High Initial Implementation Costs

Implementing robots in aerospace manufacturing processes comes with substantial initial costs. Manufacturers must carefully assess the return on investment before integrating a new robotics system. The procurement of sophisticated robots, controllers, software, and other components demands substantial capital. Regular maintenance and skilled labor for preventive maintenance adds to the expenses. Despite the high costs, order backlogs have compelled aircraft manufacturers to adopt robots in their production processes. However, the transition to fully automated processes remains a challenge due to the initial financial outlay.

The study categorizes the aerospace robotics market based on robot type, component, application, payload, and region:

Aerospace Robotics Market by Solution:

Traditional RobotsCollaborative RobotsBy Component

ControllerSensorDriveEnd EffectorBy Application

Drilling & FasteningNon-destructive Testing & InspectionWelding & SolderingSealing & DispensingProcessingHandlingAssembling & DisassemblingBy Payload

up to 16.00 kg16.01–60.00 kg60.01–225.00 kgMore than 225.00 kgBy Region

North AmericaEuropeAsia PacificMiddle EastRest of the WorldExploring Robot Types

In terms of robot types, traditional robots are set to experience significant growth from 2021 to 2026. These versatile robots are widely used in manufacturing, with applications ranging from welding, painting, assembly, and product inspection to material handling. Articulated robots, which resemble human arms, are commonly used in the aerospace industry due to their flexibility, speed, and agility.

Analyzing Components

The end effector segment is expected to exhibit the most substantial growth from 2021 to 2026. End effectors, also known as End of Arm Tooling (EOAT), play a vital role in automating repetitive tasks in industrial settings. Custom-designed end effectors are increasingly utilized for specific tasks, and there is a growing need for hybrid end effectors capable of multitasking.

A Focus on Applications

Within the aerospace robotics market, the handling segment is poised to hold a major share. Material handling robots streamline production lines, enhancing efficiency and customer satisfaction by delivering high-quality products on time. These robots excel at tasks such as part selection and transferring, palletizing, packing, and machine loading.

Regional Dynamics

The Asia Pacific region is anticipated to witness the highest growth from 2021 to 2026. This is driven by the presence of key players like Commercial Aircraft Corporation of China, Ltd. (COMAC), which offers aerospace robotics systems at competitive prices. The Indian government's policies, including 100% Foreign Direct Investment (FDI) in aerospace and manufacturing, are attracting foreign manufacturers, fostering the growth of aerospace robotics in the region.

For a More Comprehensive Analysis and Detailed Information, Download the PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=164758944

Key Market Players

Top companies dominating the aerospace robotics industry include Kuka AG (Germany), ABB Group (Switzerland), FANUC Corporation (Japan), Yaskawa Electric Corporation (Japan), and Kawasaki Heavy Industries, Ltd (Japan). These market leaders are continuously developing new products to meet evolving demands in the robotics sector.

The aerospace robotics industry is on a trajectory of steady growth, with an array of opportunities and challenges. Embracing robotic automation in aircraft manufacturing has the potential to enhance productivity, reduce labor costs, and maintain high-quality production. While initial implementation costs and the need for skilled operators present hurdles, the collaborative synergy between humans and robots promises a bright future for the aerospace robotics industry.

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America's best management consulting firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

Earlier this year, we formally transformed into one of America's best management consulting firms as per a survey conducted by Forbes.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines - TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the 'GIVE Growth' principle, we work with several Forbes Global 2000 B2B companies - helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, and facilitates analysis of interconnections through applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry.

To learn more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

Contact:

Mr. Aashish Mehra

MarketsandMarkets™ INC.

630 Dundee Road

Suite 430

Northbrook, IL 60062

USA: +1-888-600-6441

Email: sales@marketsandmarkets.com