The success of an automotive parts manufacturer /trading company is heavily dependent on a clear road map for design, testing, tooling and production on time.

After the designs are settled, automotive parts prototyping starts from here. It brings ideas to life with 3D printing, CNC machining or soft tooling techniques. Test fit and durability of function can be tested with prototypes. Selecting material at this stage helps in having fewer errors during batch production. Repeating testing and refining new designs for parts saves time downstream in the system.

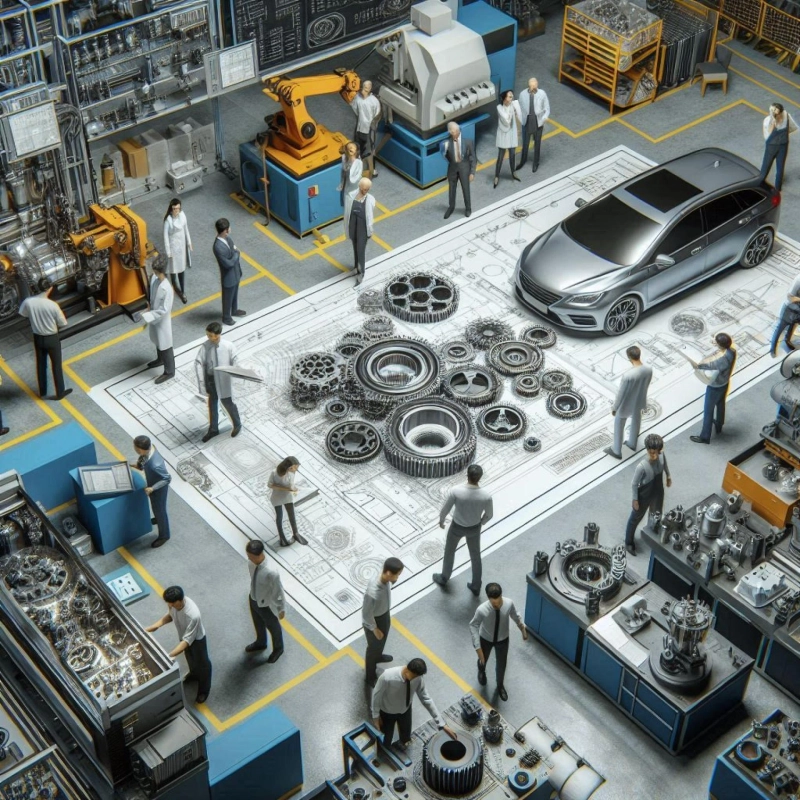

The automotive manufacturing process

These stages of the process include material sourcing, design finalization, tooling, assembly, and quality control. Scale and speed are also introduced through automation. There are inspection points in each process step. This automotive manufacturing process ensures compliance with the OEM standards and regulatory frameworks in all markets.

Strong preparation is required for prototype to production automotive evolution. This entails knowing when to put in motions, what materials to use, who should be your suppliers, etc. It helps bridge the gap with soft tooling. One of its characteristics is that it enables lower-volume production to facilitate the hard tooling needed for full-scale production. Pilot runs are conducted. In doing so, they look for bottlenecks in these small batches and optimize processes before they begin to deploy full batches.

Cost reduction

In the competitive world of today, it is imperative to Automotive manufacturing cost reduction. The essence is based on efficiency, lean practices, material savings, and all these. Value engineering is one common method of altering design slightly in order to cut material use without affecting performance or quality. Labor costs and errors are reduced with automation and the use of robotics. In addition, the per unit production costs may be reduced by sourcing raw materials in bulk.

Exploring automotive parts production methods

The automotive parts production methods can be made by casting, forging, injection molding, and stamping, depending on volume and material requirements. Dies casting is also used for precision on metal parts. Injection molding is more cost effective at scale and more flexible to design for plastic parts. For improved performance gains at a lower total cost, hybrid methods such as over-molding steel with plastic are becoming more popular.

Quality assurance

Keeping stable quality at scale is absolutely vital. In big installations, statistical process constraints and real-time monitoring are usual. These guarantee that every car component conforms to safety, environmental, and performance specifications. The packaging is perfect for avoiding damage during delivery. Labels have indicator codes and compliance stamps for legislative clarity. Logistics teams manage distribution and warehousing from there. Avoiding expensive assembly line stops depends on timely delivery.

Competitive production

Automobile components production calls for careful scheduling from concept to finished product. Competitiveness depends on good prototyping and lean manufacturing. Investing in automation, keeping abreast with technology, and emphasizing sustainability will shape the future of this changing field.

Future trends

Manufacturers currently research environmentally friendly methods. Rising are recycling of scrap, use of bio based materials, and clean energy. Additive manufacturing is becoming more popular not only in prototyping but also in low-volume production, therefore enabling on-demand component creation. Smart factories use IoT and AI to predict machine failures, track part flow, and reduce downtime, making the entire process smarter.