What Is a Bellow Sealed Valve?

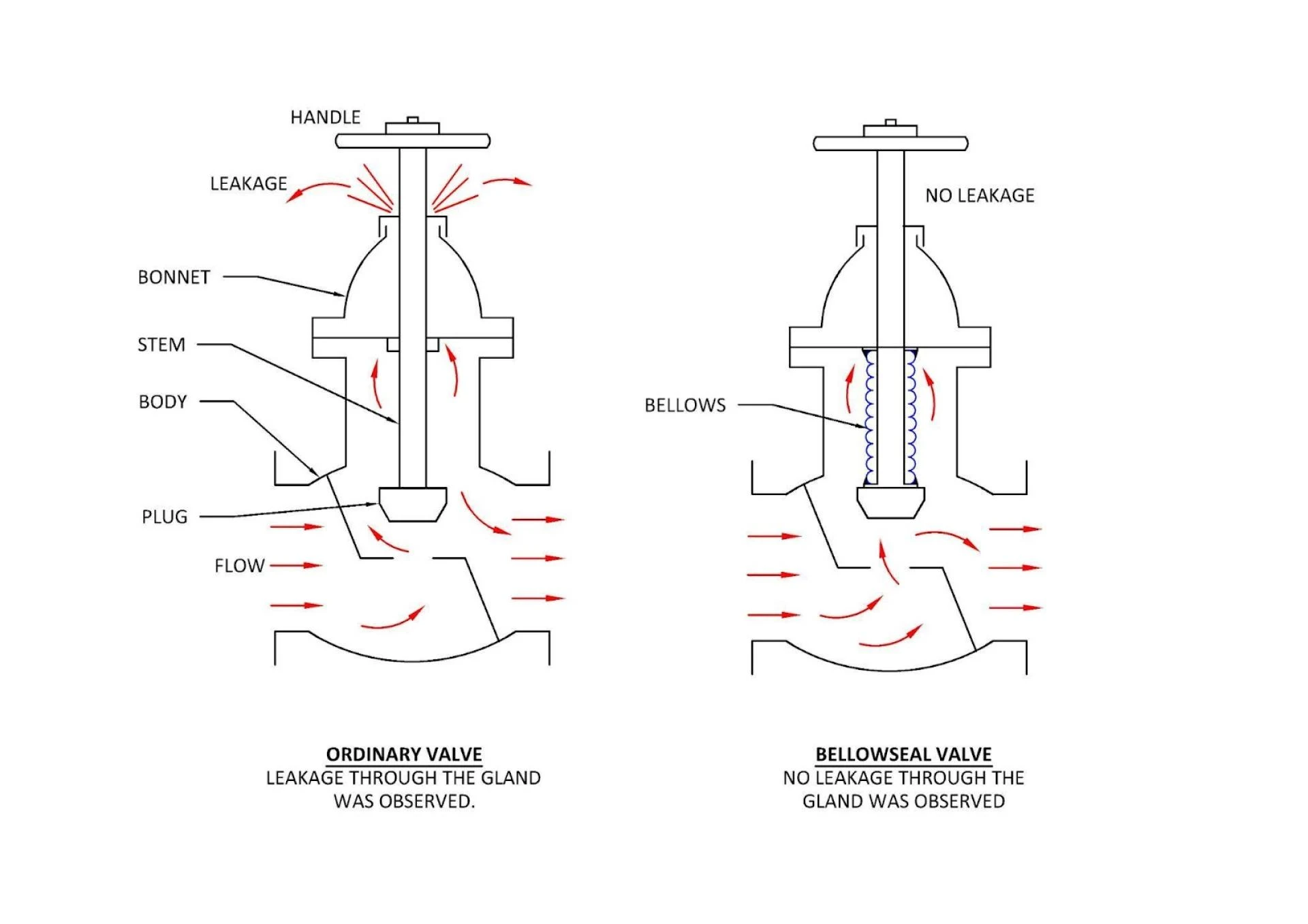

A Bellow Sealed Valve is a type of industrial valve designed with a metallic bellows assembly that isolates the process media from the stem packing. The key component—a flexible, accordion-shaped stainless steel bellow—expands and contracts with stem movement, creating a hermetic seal. This unique feature ensures that there is no leakage through the stem, which is a common failure point in conventional valves.

These valves are often configured as globe valves with bellows, offering excellent throttling capabilities. The bellows are welded to the valve stem and bonnet, completely enclosing the stem and preventing media contact, even under high pressures and temperatures.

Key Features and Benefits

- Zero Leakage Valve

- The primary benefit of bellow sealed valves is their zero leakage performance. The bellows act as a physical barrier, completely preventing the escape of hazardous gases or liquids.

- Emission-Free Valve

- These valves meet stringent environmental standards by eliminating fugitive emissions, making them ideal for industries where emission control is critical.

- Enhanced Safety

- In applications involving toxic or flammable media, safety is significantly improved with bellow seal technology. There's minimal risk of leakage that could lead to fire, contamination, or health hazards.

- Extended Service Life

- With fewer mechanical wear points and superior sealing, these valves offer long service intervals and reduced downtime.

- Maintenance Efficiency

- The design reduces the need for frequent gland packing adjustments, minimizing the overall maintenance load.

- Cost-Effectiveness Over Time

- Although the initial investment may be higher, the low maintenance and long service life deliver better total cost of ownership.

Common Applications

Bellow sealed valves are trusted in demanding environments where safety and purity are paramount:

- Petrochemical Plants – For handling volatile chemicals and preventing leaks.

- Pharmaceutical Industry – Ensuring product purity and process hygiene.

- Power Generation – Managing high-pressure steam and heat transfer fluids.

- Chemical Processing – Containing corrosive or toxic media.

- Cryogenics – Sealing at low temperatures where conventional valves may fail.

- Semiconductor Manufacturing – For ultra-high-purity applications.

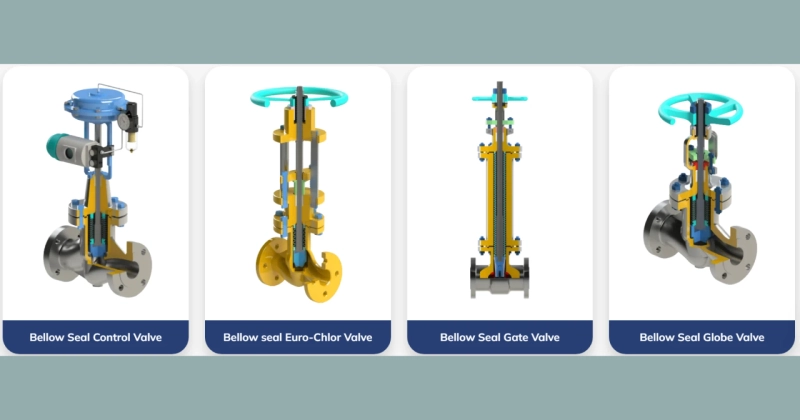

Types of Bellow Sealed Valves

Bellow sealed valves come in various configurations to meet diverse industrial needs:

- Globe Type Bellow Sealed Valve

- Offers precise throttling and flow control; most commonly used in fine-flow regulation applications.

- Gate Type Bellow Sealed Valve

- Suitable for on-off services where minimal flow resistance is required.

- Single Bellows Design

- Ideal for standard applications with moderate pressure and temperature ranges.

- Double Bellows Design

- Provides added safety with a backup bellow system, ensuring containment even if one bellows fails.

- Forged or Cast Body

- Selection depends on pressure class, temperature range, and specific industry requirements.

Comparison with Conventional Valves

Conventional globe or gate valves use stem packing (typically PTFE or graphite rings) to prevent leakage. Over time, these packings wear out or shrink, leading to leaks, especially in high-temperature or high-cycle applications.

By contrast, bellow seal globe valves eliminate this risk entirely:

- No need for regular packing adjustments

- No leakage from stem area

- Better compliance with emission regulations (e.g., TA-Luft, ISO 15848)

This makes them the preferred choice for critical applications, especially where frequent valve operation is required.

Materials and Design Standards

Bellow sealed valves are built to withstand extreme conditions. Common materials include:

- Body Materials: Stainless steel (SS304, SS316), Carbon steel, Alloy steel

- Bellows Material: SS316Ti, Inconel, Hastelloy for corrosion and fatigue resistance

They are designed and manufactured in accordance with international standards:

- ASME B16.34

- DIN EN ISO 15848 for emission control

- API 602 and BS 1873 for valve design

- TA-Luft compliance for German emission regulations

This ensures the valve's mechanical integrity, durability, and performance consistency across varied operating conditions.

Maintenance and Reliability

One of the biggest advantages of industrial valve solutions like bellow sealed valves is their reliability. With no moving parts exposed to process fluids and a fully sealed stem, the chances of mechanical failure are significantly reduced.

- Inspection: Periodic visual inspection is sufficient; no gland packing tightening required.

- Servicing Frequency: Low, due to minimal wear and tear.

- Operating Conditions: Suitable for pressure up to 100 bar and temperatures from -196°C to +450°C, depending on materials.

With proper installation and occasional checks, these valves can last for years without significant performance degradation.

Conclusion

In today's safety-conscious and environmentally regulated industrial landscape, Bellow Sealed Valves offer a superior solution for fluid control. Their zero leakage, emission-free performance, and long-term reliability make them a must-have in sectors like oil & gas, pharmaceuticals, power, and chemical processing.

By reducing emissions, enhancing safety, and minimizing maintenance needs, they contribute directly to process efficiency and compliance. For companies looking to invest in long-lasting and dependable valve solutions, bellow sealed valves represent a smart choice.

For those seeking a reliable bellow seal valve supplier in India, Freture Techno Pvt. Ltd. stands out as a trusted Bellow Sealed Valve manufacturer in Mumbai, India, offering premium-quality valves designed to meet the highest industry standards.