Introduction:

Injection molding is one of the most versatile, effective in many manufacturing processes in different industries. From automotive components to consumer electronics and medical devices, injection molding plays an important role in creating complex plastic parts with precision and consistency. In this comprehensive guide, we will delve into the intricacies of injection molding, its applications, process specifications, recent advancements, and its significant impact on modern manufacturing.

Description and basic principles of injection molding:

Summary of the process: melting, injection, cooling and ejection. Materials commonly used in injection molding include thermoplastics, thermosets, and elastomers. The main components of the injection molding machine: cylinder, screw, mold and clamping unit.

Injection molding process in detail:

Injection: forcing a solvent into a mold cavity under high pressure. Freezing: Allowing the material to harden and cool in the process.

Discharge: the release of a finished part from a mold cavity. Factors that affect each step of the process, including temperature, pressure and cycle time.

Applications of injection molding:

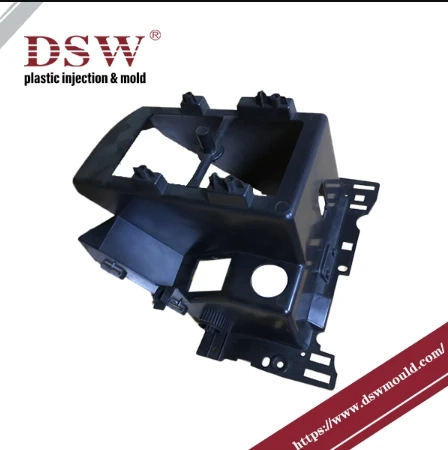

Automotive Industry: plastic moulding manufacturer of interior and exterior components, dashboard parts and engine components. Consumer Products: Production of a variety of products, including packaging boxes, home appliances and toys.

Medical Devices: Manufactures items such as syringes, medical implants and diagnostic equipment. Electronics: Components, enclosures and connectors for various electronic devices.

Aerospace: Creating lightweight, high-strength materials for aircraft and structural components. Advances in injection molding technology:

High Speed Injection Molding: Using advanced machines and control systems to achieve faster cycle times.

Microinjection Molding: Enables the production of small complex parts with micron precision. Multi-component injection molding: Adding different materials or colors to a part for better performance or decoration.

Gas injection molding helps: Gas is introduced into the mold cavity to remove parts and reduce material consumption. In-Mold Labeling (IML) and In-Mold Decorating (IMD): the insertion of decorative or functional elements directly into the molded part during the molding process.

The latest innovations in injection molding:

Bio-based polymers: Using renewable and biodegradable materials as an alternative to traditional plastics. Engineering Thermoplastics: Improved mechanical properties such as strength, stiffness and heat resistance for demanding applications.

Liquid Silicone Rubber (LSR): Provides excellent flexibility, durability and biocompatibility for medical and consumer products. Recycled Materials: Involving consumers or companies that produce recycled plastics to reduce environmental impact and promote sustainability.

Design tips for injection molding:

Wall Thickness: Optimizes part geometry to achieve uniform thickness and reduce marks of attack or sag. Draft Corner: The addition of a molded corner to facilitate the removal of the part from the mold and avoid shrinkage.

Gate design: Choosing the right gate type and location to ensure proper material flow and reduce side defects. Cooling Channels: Creating efficient cooling channels in the mold to speed up cycle times and improve part quality.

Upper end: Adjusting upper end requirements to manufacturing constraints and cost considerations. Quality control and process improvement:

Statistical Process Control (SPC): The monitoring of a process to ensure consistency and quality during production.

Moldflow Analysis: Performing an injection molding process to identify potential defects, improve part design, and reduce manufacturing risk. Automated inspection systems: Implementation of vision systems, sensors and robots for real-time inspection and defect detection.

Automated inspection systems: Implementation of vision systems, sensors and robotics for quality inspection and defect detection in real time.

Lean Manufacturing Principles: Simplify plastic molding supplier processes, reduce waste, and maximize efficiency to achieve lean, agile manufacturing operations. Future trends and prospects:

Industry 4.0 Integration: Harness the power of automation, robotics and data analytics to create intelligent, interconnected manufacturing systems.

Additive manufacturing synergies: Exploring opportunities for hybrid manufacturing approaches that combine injection molding with 3D printing technologies. Sustainable solutions: promote innovation towards closed-loop recycling systems, bio-based materials and circular economy models to minimize environmental impact.

Conclusion:

Injection molding continues to be a driving force in manufacturing, offering unprecedented versatility, precision and efficiency. With continued advances in technology, materials and process optimization, injection molding is poised to remain at the forefront of innovation, shaping industries and products for years to come. By adopting sustainable practices, leveraging cutting-edge technologies and continuously improving processes, injection molding will continue to revolutionize manufacturing and drive progress towards a more sustainable future.