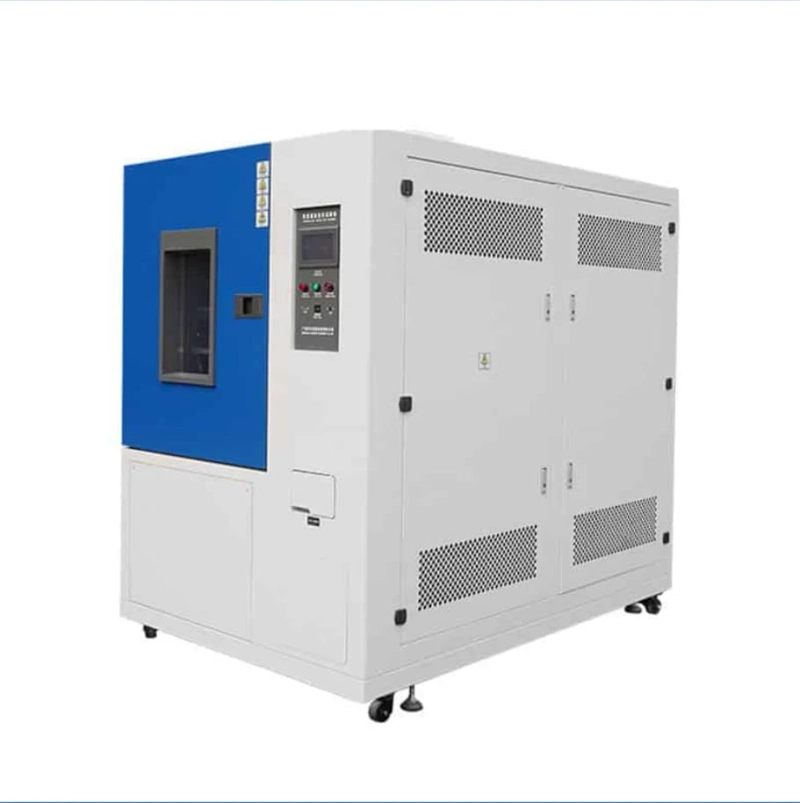

Rapid Change Temperature Chambers are versatile tools used across different industries to simulate extreme temperature variations. These chambers play a crucial role in testing the performance, reliability, and durability of various products. In this article, we will delve into the diverse applications of Rapid Change Temperature Chambers in different industries, highlighting how they contribute to product development and quality assurance.

Electronics Industry

The electronics industry relies heavily on Rapid Change Temperature Chambers to test electronic components, printed circuit boards (PCBs), and complete electronic devices. These chambers simulate temperature changes to evaluate the effects of thermal stress on electrical components and check for any changes in functionality and performance. The ability to rapidly cycle through temperatures helps identify potential weaknesses, ensuring that electronic products are robust and reliable.

Automotive Industry

In the automotive industry, Rapid Change Temperature Chambers are used to test components, such as engine parts, sensors, and electrical systems. These chambers simulate extreme temperature conditions that automotive components may experience during operation, transportation, or storage. By subjecting components to temperature cycling tests, manufacturers can validate their performance, identify potential issues, and optimize designs to ensure durability and reliability.

III. Aerospace Industry

The aerospace industry heavily relies on Rapid Change Temperature Chambers to test the durability and performance of critical components used in aerospace applications. Chambers are used to simulate the extreme temperature conditions experienced during flight, including high altitudes, rapid temperature changes, and both hot and cold environments. Testing in these chambers helps identify potential failures and adapt designs to meet the rigorous demands of aerospace applications.

Pharmaceutical Industry

In the pharmaceutical industry, Rapid Change Temperature Chambers are used for stability testing of drugs and vaccines. These chambers simulate temperature fluctuations that pharmaceutical products may encounter during manufacturing, transportation, and storage. By subjecting products to rapid temperature changes, manufacturers can evaluate their stability and the effects of temperature variations on potency and shelf life. This information is crucial for ensuring product efficacy and compliance with regulatory requirements.

Materials and Manufacturing Industries

Rapid Change Temperature Chambers find numerous applications in materials research and manufacturing industries. These chambers are used to assess how different materials and products behave under extreme temperature variations. By subjecting samples to rapid thermal cycling, manufacturers can evaluate characteristics such as thermal expansion, fatigue, dimensional stability, and mechanical properties. This information guides material selection, process optimization, and performance improvement.

Electronics and Electrical Testing Laboratories

Rapid Change Temperature Chambers are widely used in electronics and electrical testing laboratories. Such labs conduct temperature testing for compliance with industry standards and regulations. These chambers allow for accurate and repeatable temperature cycling, ensuring that products meet specific temperature requirements defined by relevant testing standards, such as IEC, ASTM, or MIL-STD.

Conclusion

Rapid Change Temperature Chambers have become indispensable tools across industries, serving a wide range of applications in product testing and development. From the electronics industry to automotive, aerospace, pharmaceutical, materials, and more, these chambers contribute to enhancing product performance, reliability, and compliance with industry standards. By enabling the simulation of extreme temperature conditions, Rapid Change Temperature Chambers assist companies in delivering high-quality products that meet customer expectations and regulatory requirements.