Carbon fiber products are widely used across various industries such as aerospace, automotive, and sports due to their high strength-to-weight ratio, stiffness, and durability. However, one of the major concerns for manufacturers and consumers of carbon fiber products is the cost associated with them. The cost of carbon fiber products is determined by several factors, which are discussed in detail below.

Quality of Carbon Fiber Material

The quality of carbon fiber material is a significant factor that influences the cost of carbon fiber products. Carbon fiber is available in various grades, and the quality of the material determines its strength and stiffness. High-quality carbon fiber materials are expensive and are used in critical applications such as aerospace and defense. On the other hand, low-quality carbon fiber materials are cheaper and are used in non-critical applications such as sporting goods.

Manufacturing Process

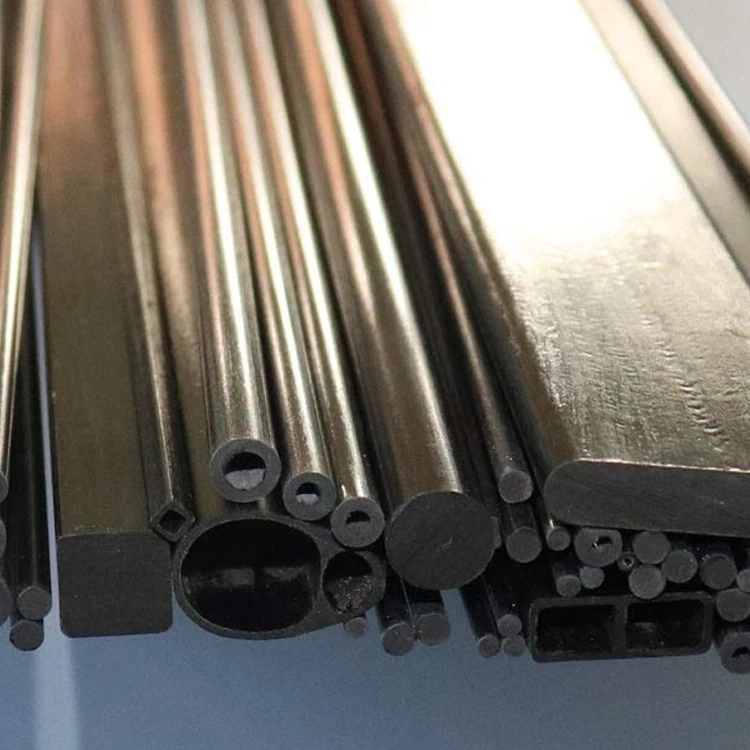

The manufacturing process used to produce carbon fiber products also plays a crucial role in determining their cost. There are several manufacturing processes for carbon fiber products, such as pultrusion, filament winding, and autoclave curing. Each manufacturing process has its advantages and disadvantages, and the cost of each process varies. Pultrusion is one of the most cost-effective manufacturing processes for carbon fiber products, which results in lower costs for carbon fiber pultruded profiles.

Design Complexity

The design complexity of carbon fiber products also influences their cost. The more complex the design, the more time and resources are required to produce the product, resulting in higher costs. Carbon fiber products with simple designs are relatively cheaper than those with complex designs. CNC carbon fiber parts are a good example of carbon fiber products that require complex designs, resulting in higher costs.

Quantity of Carbon Fiber Products

The quantity of carbon fiber products produced also affects their cost. Large-scale production of carbon fiber products results in economies of scale, reducing the cost of production per unit. On the other hand, small-scale production of carbon fiber products results in higher costs per unit due to the lack of economies of scale.

Carbon Fiber Manufacturers

The carbon fiber manufacturer is also a significant factor that influences the cost of carbon fiber products. Some carbon fiber manufacturers produce high-quality carbon fiber materials, which result in higher costs. Other carbon fiber manufacturers produce lower quality carbon fiber materials, resulting in lower costs. It is essential to choose the right carbon fiber manufacturer to ensure that the product meets the required quality standards and is cost-effective.

Transportation and Logistics

The transportation and logistics involved in the production and delivery of carbon fiber products also affect their cost. Carbon fiber products require special handling and packaging to prevent damage during transportation. The cost of transportation and logistics varies depending on the distance, mode of transportation, and type of packaging used.

Market Demand

The demand for carbon fiber products also influences their cost. High demand for carbon fiber products results in higher costs due to supply and demand dynamics. On the other hand, low demand for carbon fiber products results in lower costs due to the lack of demand.

Government Regulations

Moreover, government regulations may also affect the cost of carbon fiber products. Environmental regulations such as carbon taxes and emissions standards may increase the production costs of carbon fiber products, resulting in higher prices. Additionally, tariffs on imported carbon fiber products may increase their prices, making them less competitive in the market.

Level Of Customization Required

Another factor that can influence the cost of carbon fiber products is the level of customization required. Custom-made carbon fiber products, such as those used in the medical industry, require a higher level of precision and may take longer to produce, resulting in higher costs. In contrast, carbon fiber products that are mass-produced may be more cost-effective due to the economies of scale.

Other major factors:

Factors such as the location of the carbon fiber manufacturer, availability of raw materials, and government regulations may also influence the cost of carbon fiber products. For instance, manufacturers located in countries with higher labor costs may have higher production costs, resulting in higher prices for their products. Similarly, carbon fiber manufacturers in areas where raw materials are scarce may have to import raw materials, resulting in higher costs.

It is worth noting that the cost of carbon fiber products is not only influenced by the factors mentioned above but also by the overall market conditions. Market fluctuations such as changes in supply and demand, fluctuations in currency exchange rates, and changes in commodity prices can all affect the cost of carbon fiber products.

Conclusion

In conclusion, the cost of carbon fiber products is influenced by several factors, including the quality of carbon fiber material, manufacturing process, design complexity, quantity of products, carbon fiber manufacturers, transportation and logistics, and market demand. It is essential to consider these factors when deciding on the cost of carbon fiber products to ensure that the product meets the required quality standards and is cost-effective. Carbon fiber products such as pultruded profiles, CNC carbon fiber parts, and other carbon fiber products have different cost implications due to the factors mentioned above. Therefore, it is crucial to understand the factors that influence the cost of carbon fiber products when making purchasing decisions.