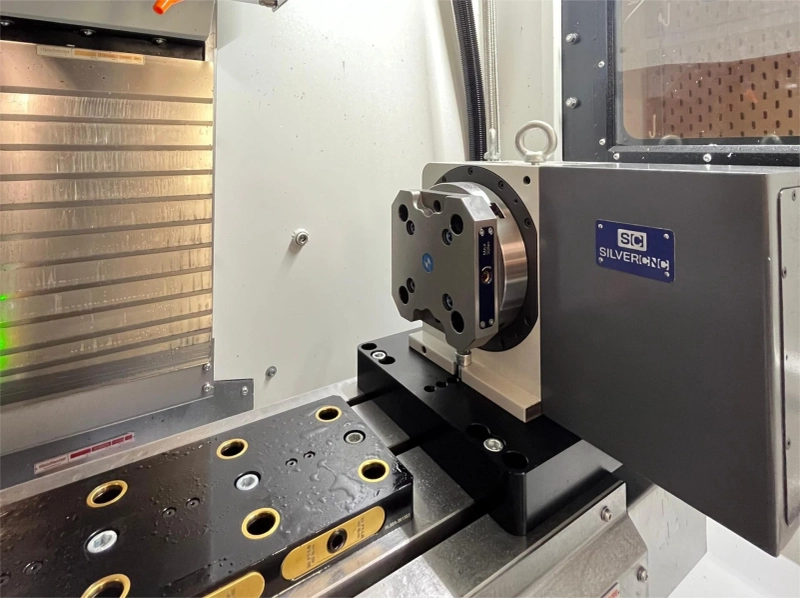

Selecting the right 4th Axis Rotary Table is a crucial decision for any CNC machining operation looking to expand capabilities, improve precision, and streamline production. A 4th axis rotary table enables machines to rotate parts around an additional axis, allowing for complex multi-side machining without manual repositioning. However, not all rotary tables are created equal, and understanding the key factors before purchasing can make the difference between enhanced performance and costly inefficiencies.

1. Load Capacity and Size

One of the first considerations when choosing a 4th Axis Rotary Table is its load capacity and size. The rotary table must be able to support the weight and dimensions of the parts you plan to machine. Underestimating load requirements can lead to premature wear, reduced precision, and potential damage to both the table and the CNC machine. Assess your typical workpiece sizes and weights to choose a model that offers sufficient capacity with room for future needs.

2. Accuracy and Repeatability

Accuracy and repeatability are critical performance indicators for any rotary table. High precision ensures that the table rotates and indexes consistently to exact positions, which is essential for maintaining tight tolerances in your parts. Look for specifications such as backlash, indexing accuracy, and repeatability values. A quality 4th axis rotary table will have minimal backlash and high repeatability, contributing directly to better machining quality.

3. Drive System: Worm Gear vs. Direct Drive

The drive system of a CNC rotary table greatly impacts its performance. Traditional worm gear systems are widely used for their cost-effectiveness, but they can introduce backlash if not properly maintained. On the other hand, direct drive rotary tables offer superior precision and smoother motion because they eliminate gears between the motor and table. While direct drive models can be more expensive, their advantages in accuracy and maintenance often justify the investment for high-precision applications.

Also Read: Applications of 4th Axis Rotary Tables

4. Motor Integration and Control

When choosing a rotary table, consider how it integrates with your CNC machine’s control system. Some 4th axis rotary tables come with built-in servo motors and controllers, while others may require separate motor mounting. Ensure compatibility with your CNC’s software and that the control interface supports indexing, continuous rotation, and any advanced features you need. Seamless integration improves job setup efficiency and reduces the learning curve for operators.

5. Build Quality and Durability

Durability should never be overlooked. A robust, well-manufactured 4th axis rotary table made from hardened steel or high-grade alloys will withstand the rigors of constant machining better than lower-quality alternatives. Check for features such as sealed bearings, hardened gearing, and corrosion-resistant finishes to ensure long-term reliability.

6. Budget and After-Sales Support

Finally, balance your budget with the value offered by the rotary table. While opting for the cheapest option may seem appealing, it can lead to higher costs over time due to maintenance issues or poor performance. Choose a supplier that offers good after-sales support, spare parts availability, and clear warranty options for peace of mind.

Enhance your CNC capabilities with a reliable 4th Axis Rotary Table that matches your machining demands. Learn more at: https://tinyurl.com/4jfa4z4h and give us a call at +86 180 9892 0890 or send us an email at liuxuan@silvercnc.com right now!