Paper and packaging units in the UAE handle a wide range of loads, temperatures and transport routes. This induces pressure on the material itself. A digital bursting strength tester helps teams to understand how a sheet or board reacts when pressure builds from one point. The reading reflects the fibre structure, coating balance and bonding quality. A burst testing machine becomes a daily equipment for anyone involved in corrugated design, carton production or reel inspection.

Understanding Bursting Strength Tester

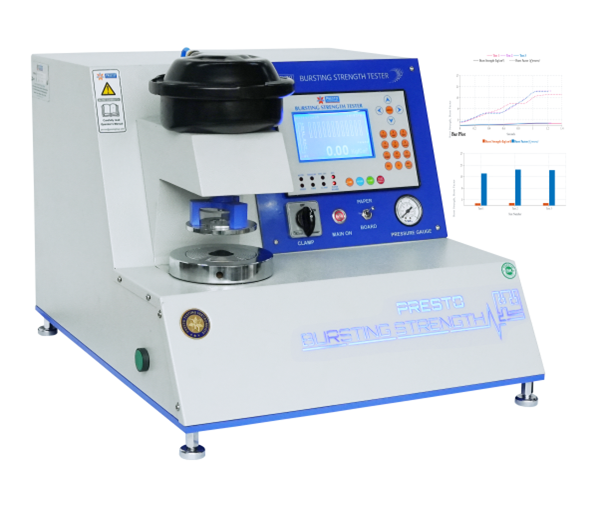

A bursting strength tester digital is engineered to quantify the pressure level at which paper, cardboard, corrugated board, or similar substrates fail under load. It uses a hydraulic system with a neoprene diaphragm that expands against the specimen until rupture occurs. Instruments such as the Burst Genie 4.0 operate through an automatic pressure-build sequence, digital indication, and peak-hold measurement, which support consistent results. The machine includes clamps, a diaphragm assembly, a pressure-generation unit, and a microprocessor-based display. Its technical design helps UAE packaging units to compare board grades, validate structural durability, and stabilise quality across production cycles.

How Digital Burst Strength Testing Helps UAE Industries Achieve Safer and Stronger Packaging?

The surge in e-commerce, retail distribution, and high-speed logistics across the Emirates has pushed packaging suppliers to work with far tighter quality margins. Basic inspection steps no longer catch hidden weaknesses in paper or corrugated board. This is where a Digital Bursting Strength Tester makes a clear difference in day-to-day production.

The machine applies controlled hydraulic pressure to a sample until it ruptures. The reading appears in kPa or PSI, giving a direct view of the material’s resistance under load. This removes guesswork and brings precision into routine checks. Teams in UAE packaging units gain more stable batch results, repeatable readings, and smooth compliance with ISO and ASTM test methods.

The impact is seen right on the production floor. Stronger burst values help cartons survive compression, rough handling, and humidity shifts seen during transport across the Emirates. It also lowers material rejection, reduces shipping damage, and adds more confidence when supplying to sectors like food, pharmaceuticals, and e-commerce.

For many UAE bursting strength tester manufacturers, this digital tester acts as a technical backbone for packaging control. It supports better decision-making, cleaner data, and a higher standard of packaging fit for the country’s fast-moving supply chain.

Principles of Digital Burst Strength Analysis: Methodology and Metrics

The digital burst strength method follows a controlled hydrostatic-pressure procedure to quantify the mechanical endurance of paper and board substrates. During testing, the sample is secured between circular clamps. A calibrated diaphragm then applies uniform hydraulic pressure until the material reaches its rupture point. The pressure value recorded at failure becomes the material’s burst strength.

Modern digital systems use high-resolution sensors, stable load-application modules, and automated peak-capture functions, which give precise readings in kPa, PSI, or kg per square centimetre. These metrics reflect the fibre bonding, stiffness, ply integrity, and structural resistance of the sheet.

UAE packaging producers rely on this analysis to monitor production batches, verify compliance with ASTM and ISO test parameters, and benchmark raw-material performance. This structured measurement process guides technical teams while selecting board grades for shipping boxes, courier packs, and heavy-duty packaging formats.

Layout of a modern burst test machine

Hydraulic pressure module: A controlled hydraulic system delivers stable pressure under the diaphragm. The fluid moves with a fixed rate, giving a clean rise to the rupture point. This stability helps when engineers compare runs across different reels.

Clamping and diaphragm assembly: Specimens sit between two rings that grip the sheet firmly. This grip avoids side leakage and gives the diaphragm a uniform stretch zone. When the break happens, it happens cleanly. The reading stays consistent across samples.

Digital sensing and peak capture: A pressure sensor sits in the line and reads micro changes. The digital display picks the exact moment the sheet breaks. This helps teams in busy UAE labs because there is no need to watch the gauge constantly. The display shifts to the peak automatically.

Automation layer: Modern units start the run with a single press. They lift pressure, hold the data, and return to rest mode automatically. Some panels show bar-graph trends for a batch of samples. This saves time when testing different boards throughout the day.

Data reporting and workflow: UAE labs often need printed records or digital logs for clients. The bursting strength machine stores readings, shows batch averages and supports simple exports. Engineers rely on this when they need quick comparisons during supplier checks.

Importance of a Digital Bursting Strength Tester for UAE Exporters

Export packaging faces long transit routes, mixed climates and stacking loads. A bursting strength tester gives a quick reading of how well the sheet will withstand pressure during these movements. This helps exporters reduce damage claims and maintain product stability.

Selecting your bursting strength tester supplier

Teams look for a supplier who offers calibration support, hands-on training, and spare parts availability. A clear maintenance plan keeps the machine stable for years. It also helps when labs run continuous testing across multiple shifts. Presto supports these needs with prompt service, trained engineers, and smooth guidance.

Conclusion

A bursting strength computerised machine brings clarity to paper and packaging checks. With digital sensors, automatic routines and stable hydraulic loading, the instrument gives clean pressure readings and quick decisions. For UAE industries, it supports daily control, supplier evaluation and export-grade packaging design.

If you want guidance on choosing the right model for your testing room or bursting strength tester price, write to response@prestogroup.com or call +91 9210903903.

FAQ’s

1. What factors influence the burst strength value during digital testing?

Fibre bonding, grammage, moisture balance, and sheet structure directly affect how much hy draulic pressure the sample can withstand before rupture.

2. Why do UAE packaging units prefer digital burst testing over manual methods?

Digital systems give controlled pressure buildup and consistent peak readings, reducing opera tor variation and aligning with standardised test methods.

3. How does a digital bursting strength machine support carton performance during transport?

Higher burst values indicate stronger resistance to internal and external loads, lowering the chance of panel failure during handling and stacking.

4. What type of materials can be evaluated with a digital burst tester?

Paper, kraft liners, duplex board, corrugated board, carton stock, and flexible paper laminates can be tested under the same hydraulic principle.

5. How often should a bursting strength tester be calibrated in a UAE manufacturing setup?

Most units are checked monthly or after heavy use to maintain stable readings under local tem perature and humidity conditions.