In the fast-paced and safety-conscious world of construction, every detail matters—especially when it comes to protecting workers, pedestrians, and property from the hazards of falling debris. As construction sites grow in complexity and scale, the need for reliable debris containment solutions has never been more critical. This is where the role of a Debris Netting Manufacturer becomes indispensable. Selecting the right manufacturer is not just a matter of compliance; it is a strategic decision that can impact the safety, efficiency, and reputation of your entire project.

At Qingdao Agrishade Mesh Co., Ltd., we understand that the market is filled with options, each promising quality and reliability. However, not all debris netting manufacturers are created equal. The right partner will offer more than just a product—they will provide expertise, customization, and ongoing support tailored to your unique project requirements. As you embark on your search for the ideal debris netting manufacturer, it is essential to consider several key factors that go beyond price and availability.

Why Debris Netting Matters in Construction

1. Ensuring Site Safety

Debris netting is a vital safety measure on any construction site. It acts as a protective barrier, preventing loose materials, tools, and debris from falling and causing injury to workers or passersby. A reputable Debris Netting Manufacturer will provide products that meet or exceed industry safety standards, ensuring peace of mind for project managers and site supervisors.

2. Regulatory Compliance

Construction regulations in most regions require the use of debris netting to protect both workers and the public. Non-compliance can result in hefty fines, project delays, and even legal action. By partnering with a reliable debris netting manufacturer, you ensure that your site meets all necessary safety codes and regulations.

3. Protecting Property and the Environment

Falling debris can damage vehicles, nearby buildings, and landscaping, leading to costly repairs and potential liability. High-quality debris netting also helps contain dust and small particles, minimizing environmental impact and maintaining a cleaner worksite.

4. Enhancing Project Reputation

A well-managed, safe construction site reflects positively on your company’s reputation. Clients, investors, and the public are more likely to trust and support projects that prioritize safety and professionalism.

Key Factors to Consider When Choosing a Debris Netting Manufacturer

1. Product Quality and Material Standards

The foundation of any effective debris netting system is the quality of the materials used. When evaluating a Debris Netting Manufacturer, consider the following:

- Material Strength: Look for netting made from high-density polyethylene (HDPE) or other durable, UV-stabilized materials that can withstand harsh weather and prolonged sun exposure.

- Mesh Size and Weight: The mesh size should be appropriate for the type of debris you need to contain. Heavier netting may be required for larger or heavier materials.

- Flame Retardancy: In some projects, especially those involving welding or hot work, flame-retardant netting is essential for added safety.

- Compliance Certifications: Ensure the manufacturer’s products meet relevant safety standards such as OSHA, EN1263, or other local regulations.

2. Customization Capabilities

Every construction project is unique, with different site layouts, heights, and safety requirements. A top-tier Debris Netting Manufacturer should offer customization options, including:

- Custom Sizes and Shapes: Ability to produce netting that fits your specific scaffolding or building dimensions.

- Color Options: Different colors may be required for visibility, branding, or compliance.

- Logo Printing: For commercial projects, having your company logo on the netting can enhance brand visibility and professionalism.

3. Manufacturing Experience and Reputation

Experience matters when it comes to safety products. Research the manufacturer’s track record:

- Years in Business: Established manufacturers are more likely to have refined their processes and quality control.

- Client Testimonials and Case Studies: Look for feedback from previous clients and examples of successful projects.

- Industry Certifications: Membership in industry associations or possession of ISO certifications can indicate a commitment to quality.

4. Technical Support and Customer Service

A reliable Debris Netting Manufacturer should provide more than just products. Consider their level of support:

- Pre-Sales Consultation: Do they offer guidance on selecting the right netting for your project?

- Installation Support: Are there clear instructions, videos, or on-site assistance available?

- After-Sales Service: Can you easily reach them for questions, replacements, or warranty claims?

5. Delivery and Lead Times

Construction schedules are often tight, and delays can be costly. Ensure your chosen manufacturer can deliver on time:

- Production Capacity: Can they handle large or urgent orders?

- Shipping Options: Are there expedited shipping or local distribution centers?

- Order Tracking: Is there a system in place to monitor your order’s progress?

6. Pricing and Value

While cost is always a consideration, the cheapest option is not always the best. Balance price with quality, support, and long-term value. A reputable Debris Netting Manufacturer will offer competitive pricing without compromising on safety or durability.

The Customization Process at Qingdao Agrishade Mesh Co., Ltd.

At Qingdao Agrishade Mesh Co., Ltd., we pride ourselves on our ability to deliver tailored solutions for every client. Here’s how our customization process works:

1. Consultation

We begin by understanding your project’s specific needs, including site dimensions, safety requirements, and any special features you require.

2. Design and Material Selection

Our team recommends the best materials and designs based on your requirements. We offer a range of mesh sizes, weights, and colors to suit any application.

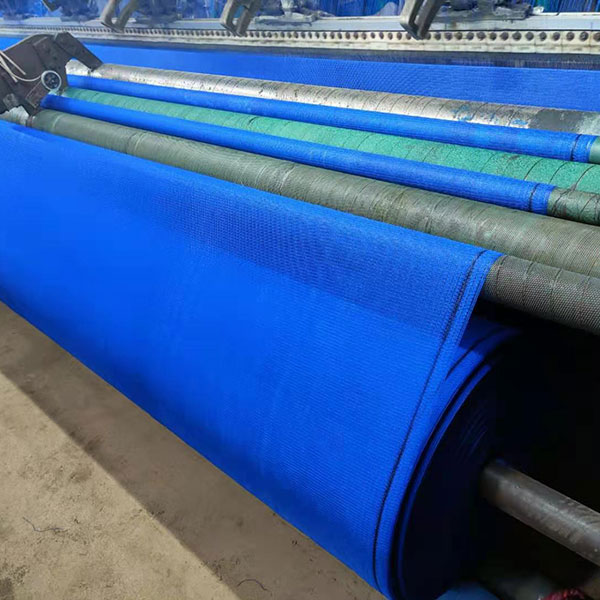

3. Manufacturing

Using state-of-the-art equipment and strict quality control, we manufacture your custom debris netting to exact specifications.

4. Delivery and Support

We ensure timely delivery and provide detailed installation instructions. Our support team is always available to answer questions or provide additional assistance.

Installation Tips for Debris Netting

1. Plan Your Layout

Before installation, map out the areas that require netting. Identify anchor points and ensure you have the correct hardware.

2. Secure Attachment

Use strong ties, clips, or hooks to attach the netting to scaffolding, frames, or other structures. Ensure the netting is taut and free of sagging.

3. Overlap and Coverage

For maximum protection, overlap sections of netting and secure all edges. Pay special attention to corners and high-traffic areas.

4. Regular Inspections

Inspect the netting regularly for signs of wear, damage, or loose attachments. Replace or repair any compromised sections immediately.

Also Read: Debris Netting Manufacturers - Qingdao Agrishade Mesh Co., Ltd.

Maintenance and Care

1. Cleaning

Remove dust and debris regularly to maintain visibility and effectiveness. Use mild soap and water for cleaning if necessary.

2. Storage

When not in use, store netting in a dry, shaded area to prevent UV degradation and prolong its lifespan.

3. Repairs

Small tears or holes can often be repaired with patch kits. For larger damage, contact your Debris Netting Manufacturer for replacement options.

The Qingdao Agrishade Mesh Co., Ltd. Advantage

1. Proven Expertise

With years of experience as a leading Debris Netting Manufacturer, we have supplied products to projects of all sizes, from residential builds to major infrastructure developments.

2. Quality Assurance

Our products undergo rigorous testing to ensure they meet or exceed industry standards for strength, durability, and safety.

3. Custom Solutions

We offer a wide range of customization options to meet the unique needs of your project.

4. Dedicated Support

Our team is committed to providing exceptional customer service, from initial consultation to after-sales support.

5. Competitive Pricing

We offer high-quality products at competitive prices, ensuring you get the best value for your investment.

Choosing the right Debris Netting Manufacturer is a critical step in ensuring the safety, efficiency, and success of your construction project. By considering factors such as product quality, customization capabilities, experience, and customer support, you can make an informed decision that protects your workers, property, and reputation.

Frequently Asked Questions (FAQ)

1. What should I look for in a Debris Netting Manufacturer?

Look for a manufacturer with a proven track record, high-quality materials, customization options, strong customer support, and compliance with safety standards.

2. How do I know if the netting meets safety regulations?

Ask for documentation or certifications that demonstrate compliance with relevant standards such as OSHA, EN1263, or local regulations.

3. Can I order custom sizes or colors?

Yes, most reputable manufacturers, including Qingdao Agrishade Mesh Co., Ltd., offer custom sizes, shapes, and colors to fit your project’s needs.

4. How long does it take to receive my order?

Lead times vary depending on order size and customization requirements. We strive to deliver orders as quickly as possible and offer expedited shipping options.

5. Is installation support available?

We provide detailed installation instructions and are available to answer any questions you may have during the installation process.

6. What materials are used in your debris netting?

Our netting is made from high-density polyethylene (HDPE) or other durable, UV-stabilized materials designed for long-lasting performance.

7. Are your products flame retardant?

We offer flame-retardant options for projects where fire safety is a concern. Please specify your requirements when placing your order.

8. How do I maintain and clean the netting?

Regularly remove dust and debris, and clean with mild soap and water as needed. Store in a dry, shaded area when not in use.

9. What if my netting is damaged?

Small repairs can be made with patch kits. For significant damage, contact us for replacement options.

10. How do I place an order with Qingdao Agrishade Mesh Co., Ltd.?

Contact our sales team with your project details. We will guide you through the customization process, provide a quote, and ensure timely delivery.