The Hidden Industry Behind Aviation Innovation

While aircraft manufacturers like Boeing, Airbus, and Lockheed Martin capture headlines, rugged display manufacturers work behind the scenes engineering the critical human-machine interfaces that define modern cockpit display systems. These specialized companies bridge the gap between consumer display technology and the extreme reliability requirements of aviation, translating advances in LCD panels, touch sensors, and graphics processors into products capable of surviving decades in hostile environments. Understanding how these manufacturers operate reveals the sophisticated engineering ecosystem supporting every modern cockpit.

From Commercial Displays to Aerospace-Grade Solutions

Rugged display manufacturers don’t simply harden consumer electronics—they fundamentally re-engineer every aspect of display technology. The process begins with sourcing display panels from LCD manufacturers like Samsung, LG Display, or AU Optechs, then extensively modifying them for aerospace applications. Commercial panels use adhesives and sealants optimized for benign environments and short lifecycles; aerospace applications demand materials stable from -55°C to +85°C over decades of thermal cycling.

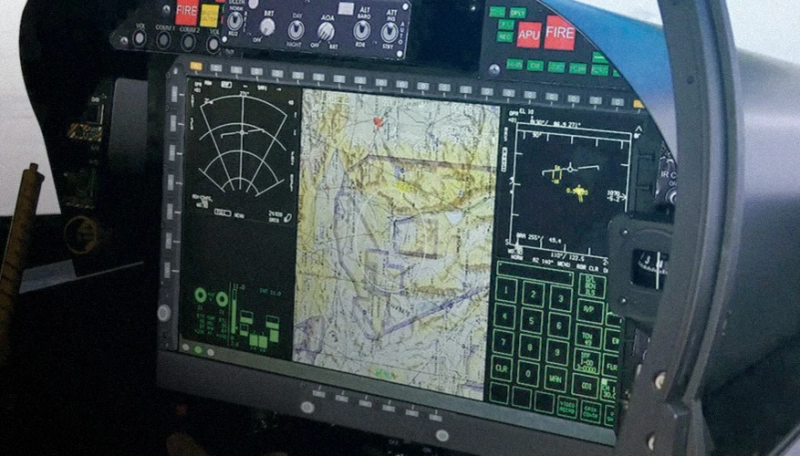

Optical bonding—the process of eliminating air gaps between display layers—represents a core competency distinguishing aerospace rugged display manufacturers from industrial display suppliers. Air gaps cause parallax errors making accurate touch targeting difficult, trap moisture leading to delamination, and degrade sunlight readability. Military-grade optical bonding uses specialized adhesives maintaining optical clarity across temperature extremes while providing mechanical coupling that maintains touch calibration under vibration.

The Engineering Challenge: Balancing Competing Requirements

Cockpit display system development demands balancing contradictory requirements. Pilots need maximum brightness for sunlight readability, yet high brightness consumes power and generates heat that accelerates component aging. Touch sensitivity must accommodate thick flight gloves without becoming so sensitive that turbulence or rain triggers false touches. Display weight must minimize to reduce aircraft empty weight and improve performance, yet ruggedization inherently adds mass through thicker glass, reinforced housings, and shock isolation systems.

Design engineers at rugged display manufacturers employ sophisticated modeling and simulation to optimize these tradeoffs before committing to expensive prototype fabrication. Finite element analysis predicts mechanical stress under shock and vibration loads. Thermal modeling ensures adequate cooling without excessive airflow that could introduce contaminants. Optical ray tracing optimizes anti-reflective coatings and viewing angle performance. This computational engineering reduces development cycles while improving first-pass design success rates.

Qualification Testing That Defines Reliability

The most rigorous phase of cockpit display system development involves comprehensive environmental qualification. Rugged display manufacturers subject prototypes to test sequences deliberately designed to identify failure modes: rapid thermal cycling between temperature extremes, prolonged exposure to maximum temperatures, multi-axis vibration matching platform-specific profiles, mechanical shock simulating hard landings or weapons release, and altitude chamber testing validating operation at 50,000+ feet.

Testing doesn’t simply verify pass/fail against specifications - it provides data driving design improvements. When displays fail qualification tests, engineers analyze failure mechanisms through materials analysis, optical inspection, and component-level testing. This failure analysis reveals whether problems stem from design inadequacies, manufacturing process variations, or component quality issues. Iterative testing and redesign continues until displays not merely pass qualification but demonstrate substantial margins above minimum requirements.

Leading rugged display manufacturers like Aeromaoz, globally recognized for mission-critical display solutions, maintain comprehensive test facilities enabling rapid iteration without dependence on external test houses. This vertical integration accelerates development while building institutional knowledge about failure modes and design margins that translates into more reliable products.

Manufacturing Processes Ensuring Consistency

Laboratory prototypes meeting qualification requirements mean nothing if production units don’t deliver equivalent performance. Rugged display manufacturers implement quality management systems ensuring manufacturing consistency. ISO 9001 certification provides baseline quality assurance; AS9100 aerospace supplements add aviation-specific requirements. Defense contractors additionally implement stringent supply chain security preventing counterfeit components from entering production.

Statistical process control monitors critical manufacturing parameters, identifying process drift before it produces defective units. Every display undergoes 100% functional testing at temperature extremes before shipping - a standard practice in aerospace manufacturing but uncommon in commercial electronics. Traceability systems track every component serial number, enabling rapid identification if field failures indicate systematic problems.

Customization Capabilities Driving Innovation

Off-the-shelf cockpit display systems suit many applications, but next-generation platforms increasingly demand customization. Rugged display manufacturers with flexible engineering organizations can modify standard products for platform-specific requirements: unusual mounting configurations, proprietary communication protocols, custom graphics overlays, or integration with specific avionics suites. This customization capability particularly benefits system integrators at companies like Thales, Honeywell, and Rockwell Collins who need displays optimized for their avionics architectures.

Customization requires deep engineering capability and manufacturing flexibility that large, process-driven organizations struggle to accommodate economically. Mid-tier rugged display manufacturers often excel at custom solutions, leveraging design expertise and agile manufacturing to deliver platform-optimized displays competitive with mass-produced alternatives while meeting unique requirements.

Obsolescence Management and Lifecycle Support

Cockpit display system lifecycles often exceed component availability from electronics manufacturers. LCD panels, processors, and specialized components may become obsolete years before aircraft retire. Responsible rugged display manufacturers implement obsolescence management programs identifying at-risk components and qualifying replacements before supply interruptions occur. Some manufacturers stockpile critical components ensuring availability throughout anticipated platform lifecycles.

When component obsolescence makes identical reproduction impossible, manufacturers must qualify modified designs delivering equivalent performance while maintaining form, fit, and function compatibility with existing installations. This requires retaining engineering expertise and manufacturing capabilities throughout platform lifecycles - a significant commitment distinguishing manufacturers viewing displays as long-term partnerships from those treating them as commodity products.

The Future of Cockpit Display Innovation

Rugged display manufacturers continue pushing technological boundaries. MicroLED displays promise revolutionary improvements in brightness, power efficiency, and operational temperature range. Flexible displays enable conformal integration with curved cockpit surfaces. Haptic feedback provides tactile confirmation of touch inputs during eyes-out operations. Augmented reality overlays merge synthetic vision with real-world views. These innovations require rugged display manufacturers to master entirely new technologies while maintaining the fundamental reliability aviation demands.

The world of rugged display manufacturers shaping modern cockpit display systems represents a sophisticated ecosystem of specialized engineering, rigorous qualification, and long-term partnership - essential yet often invisible contributors to aviation safety and capability.