In today's fast-paced manufacturing environment, the demand for precision-engineered, high-performance packaging is higher than ever. From delicate electronic components and pharmaceutical trays to food containers and offset-printed packaging, industries are in constant pursuit of durable, efficient, and aesthetic solutions. This evolution in product protection and presentation has brought pressure thermoforming technology into the spotlight—delivering unmatched speed, precision, and flexibility.

At Shanghai Zhanshi Mechanical Equipment Co., Ltd., we’ve experienced first-hand how the right Pressure Thermoforming Machine can revolutionize packaging lines with its superior forming capabilities and industry-grade precision. Leveraging both cutting-edge materials and customizable molding techniques, these machines offer manufacturers a smart, scalable way to produce complex trays, containers, lids, and custom packaging without compromising on quality or throughput.

What Is a Pressure Thermoforming Machine?

Pressure thermoforming Machine is a high-precision plastic forming technique that uses compressed air (up to 5 bar/73 PSI) to force a heated plastic sheet against a mold. This process creates highly detailed and structurally consistent packaging products—even with complex surface textures or deep draw depths.

Unlike traditional vacuum forming, which relies primarily on suction to shape the plastic, pressure forming uses external positive air pressure alongside vacuum to enhance form fidelity. This allows manufacturers to produce packaging that mimics injection-molded quality—at a fraction of the tooling cost and with faster cycle times.

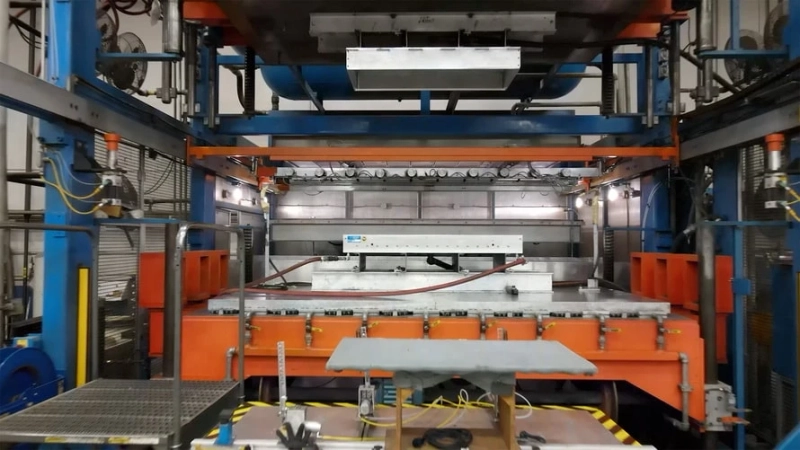

Anatomy of a Pressure Thermoforming Machine

Modern Pressure Thermoforming Machines consist of sophisticated sub-systems that ensure each part is molded perfectly, quickly, and repeatably.

Key Components Include:

🔥 Sheet Heating Unit – Infrared or quartz heaters with zone control

💨 Positive Pressure Unit – Injects compressed air during forming

🌀 Vacuum Unit – Supports tight mold adherence

⛓ Clamping System – Keeps material aligned and taut

🧩 Mold Station – Customizable molds with temperature regulation

🖥 Control System (PLC/HMI interface) – User-defined presets and diagnostics

🪚 Trimming & Stacking Stations (optional) – For inline processing

At Shanghai Zhanshi Mechanical Equipment Co., Ltd., we design machines with modular architecture to meet the unique needs of both low- and high-volume manufacturing environments.

Also Read: Pressure Thermoforming Machine Industries Application [Infographic]

Key Benefits of Pressure Thermoforming in Advanced Packaging

Let’s explore what makes this process so vital for next-generation packaging:

✅ 1. Exceptional Detail Accuracy

Pressure forming allows sharper corners, embossing, logos, and surface textures—even on thin-gauge sheets.

✅ 2. Better Wall Uniformity

Unlike vacuum forming, pressure forming provides consistent wall thickness—even with deeper draws.

✅ 3. Reduced Material Costs

Achieve the same product strength using thinner plastics, reducing per-unit cost without sacrificing quality.

✅ 4. Shorter Tooling Lead Time

Tooling can be ready in weeks, not months—a significant advantage for seasonal or custom packaging.

✅ 5. Recyclable and Sustainable Options

Use of recyclable polymers like PET, rPET, and PLA allows compliance with green packaging initiatives.

Also Read: The Advantages of Pressure Thermoforming Machine [Infographic]

Industries That Benefit from Pressure Thermoforming

The precision and reproducibility of Pressure Thermoforming Machines make them ideal for:

🥗 Food & Beverage Packaging – Salad containers, deli trays, sushi lids

💊 Medical & Pharmaceutical – Sterile blister packs, surgical trays

📱 Consumer Electronics – Anti-static component trays, decorative enclosures

🔩 Industrial Tooling – Transport trays for automotive parts, thick-gauge inserts

🧪 Laboratory Supplies – Thin-walled custom trays, sampling kits

Our machines at Shanghai Zhanshi Mechanical Equipment Co., Ltd. can be configured with specialty molds for niche industries and multi-layer packaging materials.

Customization & Automation in Pressure Thermoforming Machines

Modern operations demand flexibility without sacrificing throughput. That’s where automation comes in:

🛠️ Automation Features We Offer:

- Servo-driven mold lifters

- Automatic sheet feeding

- Real-time temperature sensors

- Die-cut stations

- Robotic stacking systems

- Inline waste recycling modules

Additionally, we provide custom molds and software integrations for Industry 4.0 compatibility—allowing engineers to adjust settings remotely, track productivity, and create repeatable workflows.

Why Work with Shanghai Zhanshi Mechanical Equipment Co., Ltd.?

As a trusted manufacturer of Pressure Thermoforming Machines, Shanghai Zhanshi has earned its reputation for precision engineering and responsive service.

✅ Our Advantages Include:

- Decades of global export experience

- Transparent pre-sale consultation

- One-stop service including mold design, integration, and maintenance

- International certifications (ISO, CE, ROHS)

- Fully customized OEM/ODM machine ranges

- Fast deployment and virtual/on-site support

Our mission is to make advanced packaging accessible—by offering intelligent solutions, not just machines.

Precision Meets Performance

The packaging of tomorrow demands speed, structure, and sustainability—delivered at scale. A Pressure Thermoforming Machine, when chosen correctly, empowers manufacturers to meet these demands while ensuring high-quality product presentation and protection.

Frequently Asked Questions (FAQ)

Q1: What materials can be used on a pressure thermoforming machine?

A: Materials like PET, rPET, PP, PS, PVC, and even sustainable options like PLA and composite laminates can be processed effectively with our equipment.

Q2: How is pressure forming better than vacuum forming?

A: Pressure forming allows sharper definition, thinner walls, and complex geometries that vacuum forming alone cannot achieve. It's ideal for branding and medical packaging.

Q3: What maintenance is required?

A: Regular maintenance involves filter cleaning, pump inspection, heating element calibration, and software updates. We provide detailed checklists and remote diagnostics.

Q4: Do you provide turnkey solutions?

A: Yes! From machine setup to custom tooling, operator training, and even material sourcing—we handle it all.

Q5: Is pressure thermoforming eco-friendly?

A: Yes. The process allows for minimal material waste, recyclable plastics, and lower energy usage than injection molding.

Q6: Can your machines support medical-grade packaging?

A: Absolutely. We offer cleanroom-compatible machines for sterile medical and pharma trays, complete with regulatory documentation.

Q7: Can I integrate AI or smart factory tech?

A: Yes, our newer machines support IoT sensors, data analytics, and PLC-SCADA systems for smart-factory integration.