Millwork projects demand precision and efficiency; small errors in drafting can lead to costly rework, material waste, and project delays. Whether you’re working on custom cabinetry, architectural millwork, or commercial fixtures, ensuring seamless coordination between design and manufacturing is essential.

Microvellum is a powerful CAD/CAM software that helps millwork professionals automate drafting, integrate with CNC machinery, and improve workflow efficiency. It minimizes manual effort, reduces errors, and enables the creation of highly detailed shop drawings that streamline the production process.

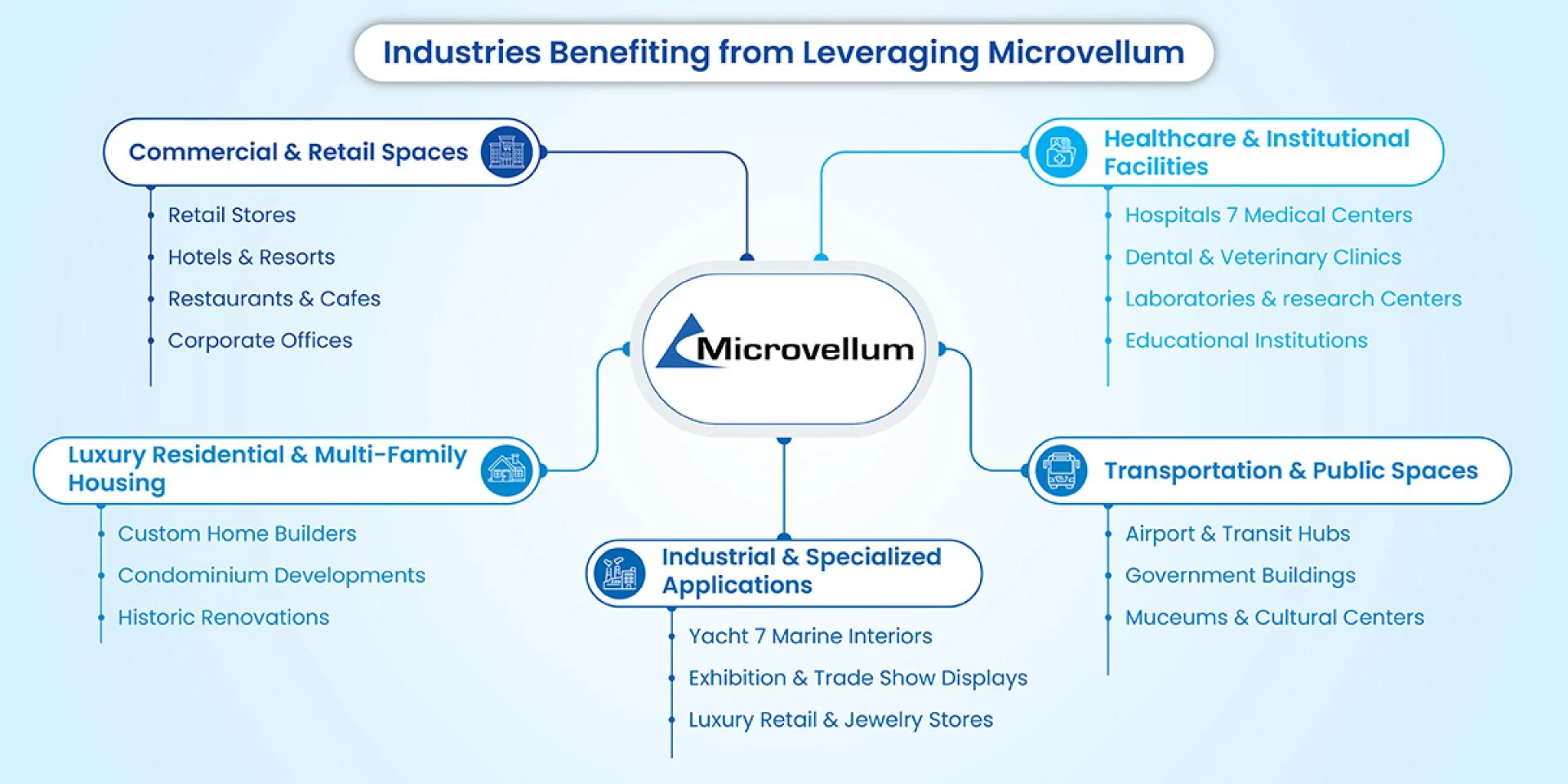

For businesses that require custom millwork, including retail stores, hospitals, airports, hotels, and corporate offices, understanding how this software works can significantly improve project outcomes. This blog explores how Microvellum optimizes drafting, enhances precision, and simplifies the design-to-manufacturing process.

Understanding Microvellum and its role in millwork design

What is Microvellum?

Microvellum is an industry-leading CAD/CAM software program designed specifically for custom millwork, cabinetry, and architectural woodworking. It provides an integrated platform for drafting, engineering, and manufacturing, enabling seamless collaboration between designers and fabricators.

Microvellum enhances precision, efficiency, and automation throughout the entire millwork process, from concept to production. By using parametric modeling and automated drafting tools, professionals can produce error-free shop drawings and CNC-ready designs.

Core features that set Microvellum apart

- Parametric Modeling: Enables dynamic design adjustments without the need to redraw from scratch.

- Automated Material Calculations: Ensures accurate estimates for wood, hardware, and fasteners, reducing waste.

- 3D Visualization: Provides realistic previews of designs, improving client approval processes.

- CNC Integration: Facilitates seamless design-to-production transfer for automated machining.

How Microvellum enhances custom millwork drafting efficiency

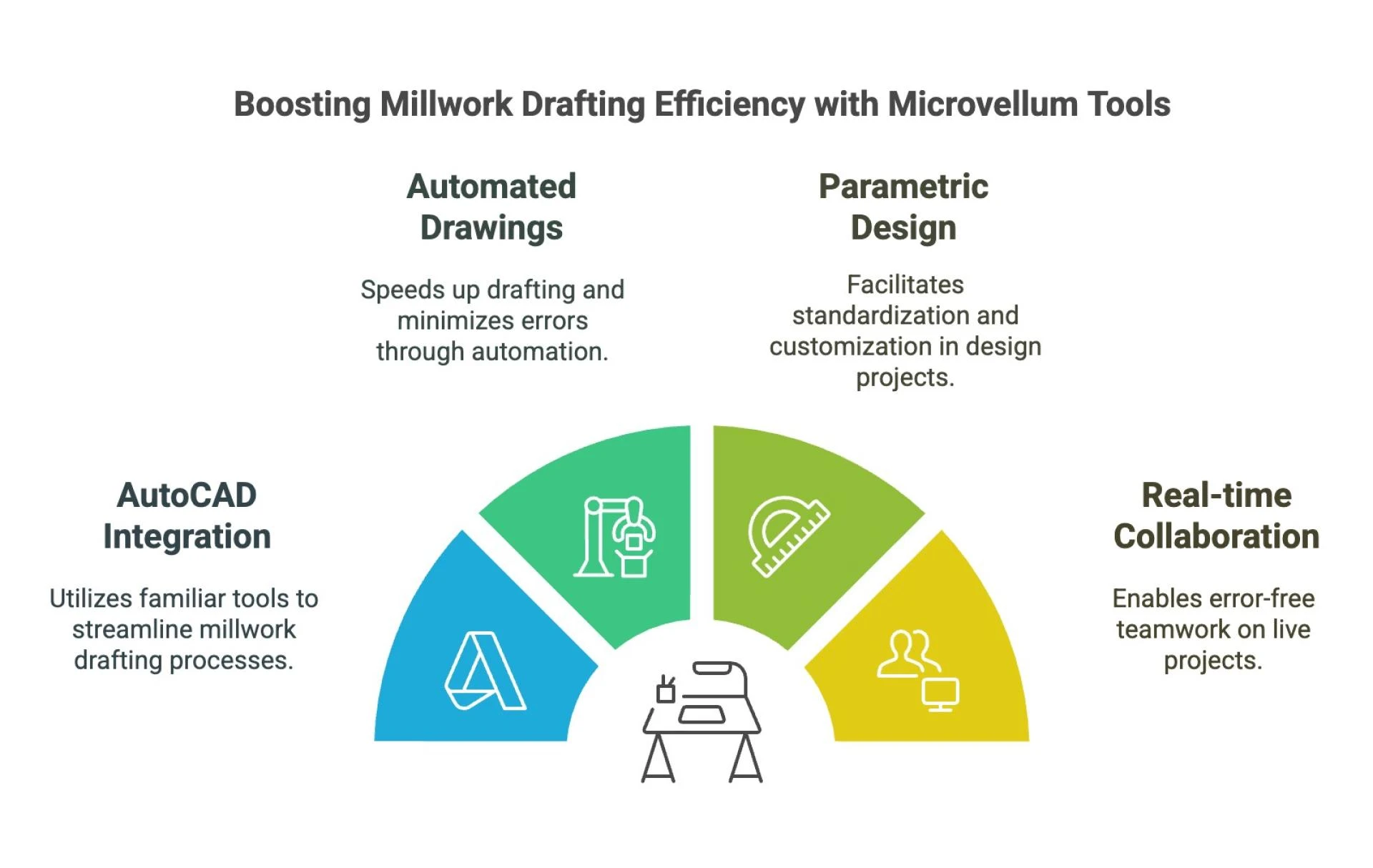

Accurate and detailed shop drawings are essential for high-quality millwork production. Microvellum optimizes drafting efficiency by integrating automation and smart design features, helping millwork professionals reduce errors, improve customization, and streamline collaboration.

- AutoCAD Integration: Built on AutoCAD, Microvellum allows designers to leverage familiar drafting tools while adding advanced millwork-specific capabilities.

- Automated Shop Drawings: The software automatically generates shop drawings, reducing manual drafting time and improving accuracy.

- Parametric Design Capabilities: Allows for easy customization of dimensions and configurations, enabling faster project modifications without starting from scratch.

- Real-Time Collaboration Tools: Teams can work on the same project files simultaneously, ensuring alignment between design, engineering, and manufacturing.

By automating repetitive drafting tasks and improving precision, Microvellum helps millwork professionals speed up project timelines while maintaining high-quality standards.

Streamlining the design-to-manufacturing workflow with Microvellum

Beyond drafting, Microvellum ensures a seamless transition from design to production, reducing material waste and improving manufacturing efficiency.

How Microvellum optimizes production

- Direct CNC Machine Integration: Eliminates manual programming by converting designs into machine-ready CNC code.

- Material Optimization & Waste Reduction: Uses nesting algorithms to optimize material usage and minimize offcuts.

- Automation in Cabinetry & Millwork Production: Speeds up production workflows, improving efficiency for both small-scale and high-volume projects.

- Compliance with Industry Standards: Meets AWI (Architectural Woodwork Institute) and AWMAC (Architectural Woodwork Manufacturers Association of Canada) standards, ensuring all designs follow professional guidelines.

By eliminating manual production bottlenecks and ensuring consistent, high-quality output, Microvellum maximizes efficiency, accuracy, and cost-effectiveness in millwork manufacturing.

Real-world applications and benefits of Microvellum

How Microvellum benefits cabinetry manufacturers

Custom cabinetry requires precision, flexibility, and efficient workflows to meet the growing demand for tailored storage solutions in homes, offices, and commercial spaces. Microvellum helps cabinetry manufacturers automate drafting, improve customization, and streamline production workflows.

1. Faster and more accurate shop drawings

- Automated drafting tools generate highly detailed shop drawings in minutes, reducing manual effort.

- Smart libraries with parametric components allow quick modifications to cabinets, drawers, and shelving.

- Preconfigured industry-standard templates ensure compliance with construction codes and material specifications.

2. Precision in measurements and customization

- Parametric modeling ensures dynamic adjustments to cabinet sizes and layouts without redrawing.

- Material and hardware specifications are assigned automatically, ensuring consistency across projects.

- Advanced nesting algorithms optimize cutting patterns, reducing waste and maximizing material use.

3. Seamless transition from design to production

- CNC integration eliminates manual programming, ensuring faster and error-free fabrication.

- Automated cut lists and labeling improve organization, reducing assembly time.

- Cloud-based collaboration tools allow design and production teams to work in sync, preventing miscommunication.

Impact on architectural millwork firms

Architectural millwork projects require high-end detailing, intricate customization, and precise fabrication. Microvellum helps architectural millwork firms streamline design, improve efficiency, and optimize material usage.

1. More accurate and customizable designs

- Dynamic parametric modeling allows architects to modify designs without rework.

- Flexible libraries support the creation of custom moldings, paneling, and decorative elements.

- AutoCAD integration ensures compatibility with architectural drawings.

2. Faster production and installation

- Automated shop drawings reduce revision time and speed up production.

- Pre-cut, labeled components simplify on-site assembly and installation.

- 3D visualization tools help clients approve designs before production, preventing last-minute changes.

3. Reduced rework and cost savings on high-end materials

- Automated error detection helps identify design flaws before fabrication, reducing rework.

- Material optimization tools minimize waste, making high-end materials more cost-effective.

- CNC automation ensures precision in carvings, joinery, and complex wood detailing.

By leveraging Microvellum’s automation and precision-driven features, cabinetry manufacturers and architectural millwork firms can streamline production, reduce errors, and improve profitability while delivering high-quality custom solutions.

Microvellum makes your millwork projects smoother and stress-free

Whether you’re designing custom cabinetry, commercial fixtures, or architectural millwork, project success depends on precision, efficiency, and seamless execution.

Why Microvellum matters for your millwork project

- Ensures drafting accuracy, reducing costly mistakes and rework.

- Automates production workflows, improving efficiency.

- Optimizes material usage, cutting down waste and costs.

- Meets industry standards, ensuring compliance with architectural guidelines.

Why work with a professional who uses Microvellum?

Instead of navigating the technical complexities of millwork drafting and production, partnering with an expert who uses Microvellum ensures:

- Your designs are engineered for precision.

- The project stays on budget with optimized material usage.

- Shop drawings are CNC-ready for fast and efficient production.

Looking to simplify your millwork project? Work with a millwork drafting professional who leverages Microvellum to ensure a smooth, high-quality outcome.