Semiconductors have evolved as a piece of essential equipment. We require them for mobile phones, vehicles, washing machines, and many other things. But what are semiconductors, and why do their count remain too few? Why do semiconductors need to be manufactured in clean rooms? And how is a wafer handling robot helpful in semiconductor production and handling?

What are Semiconductors?

Microchips or semiconductors are the main components of all digital assistance. They are all made of semiconductors, a material with electrical conductivity, especially silicon. The small plates have complicated electrical circuits.

Need for Semiconductors?

In the absence of semiconductors, there are no semiconductor chips or microchips. As a result, there is no digital world without microchips. Because each product that is halfway smart and intelligent has a chip in it, you won't believe that even a modern toothbrush is incomplete without having the semiconductor chips. The modern toothbrush also has two semiconductor chips in it.

Reasons for the Semiconductor Crisis?

The world is continuously moving towards more digitized opportunities, which is why the demands for semiconductor chips are constantly increasing.

Moreover, the few semiconductor manufacturers in the market, a few have them have the capability to fulfil the demand for more powerful semiconductor chips. The semiconductor chip manufacturing is pretty complicated, and the process takes several weeks to produce a semiconductor chip. All these factors contribute to the crisis in the semiconductor industry.

In addition to this, other factors have also contributed to the shortage of semiconductor chips by the end of the year 2020.

Natural Disasters and Fires

Approximately 12 percent of the global microchips demand is fulfilled by the USA, with a significant proportion fulfilled by Texas. In February 2021, a massive snowstorm lead to a significant power outage. As a result, the manufacturing of semiconductor chips had to be shut down for several weeks. The restart of production took weeks.

In Japan, production was also halted due to the fire in the semiconductor chip production plant. It is the third-largest supplier of automotive semiconductor chips. It results in 1.5 million fewer productions of cars.

Global Pandemic Crisis

Life migrated even further to the digital domain due to the pandemic. Electronic device demand soared: Smartphones and laptops were the primary means of communication, while game consoles became a recreational activity. Lockdowns, home offices, and homeschooling forced people to spend much of their time inside their own four walls. Lockdowns also impacted semiconductor producers, limiting the number of products that could be manufactured.

How to Overcome Microchips Crises?

Naturally, semiconductor companies have responded by spending heavily on expanding their production capacities. However, this does not happen immediately due to the complexity of semiconductor fabrication.

Why are Semiconductors produced in Clean Room?

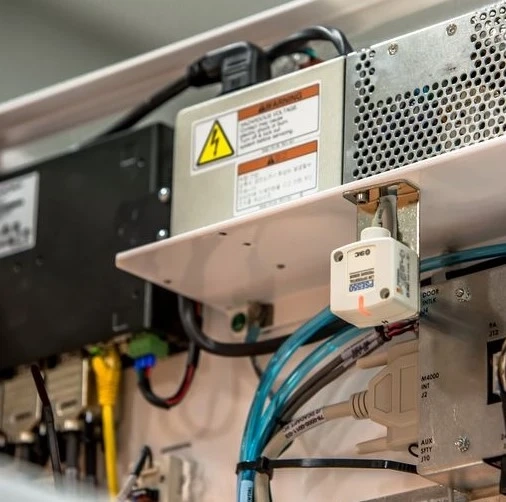

A microchip's components are extremely small. Because the structures and processes are so sensitive, every particle impacts the final product's quality. Semiconductor makers strive to maintain their manufacturing environments as free of particles as possible. It is for this reason that they are manufactured in clean rooms. AMAT robots and wafer handling robots are helpful in this.