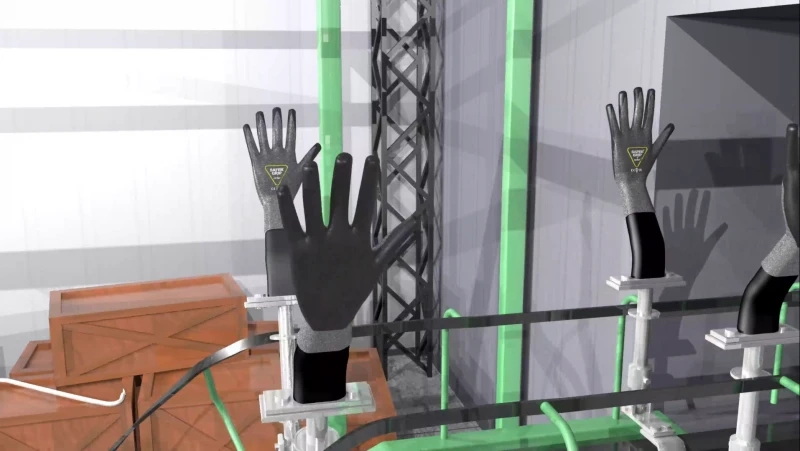

Protecting your hands should be your top priority, and the best way is to use work gloves. Yes, these work gloves are great as they provide a layer of protection to the knit gloves and give a non-slippery experience.

Gloves can be made of nylon, cotton, and even polyester or engineered yards called Kevlar or Dyneema. This material is an excellent alternative for expensive leather gloves.

The palm-coated industrial work gloves are great for different use in the automotive industry, construction, or even in sampling and handling products, which offer a better, and anti-slip grip.

The dip coating is applied on the knit gloves to give a good layer of protection. However, the amount of coating can be customized as follows:

Full Dip

The full dip allows covering the whole hand including the lower wrist.

Palm Dip

The palm dip will cover the whole palm including the fingertips for a better shield.

¾ Dip

The ¾ dip protects the palm, knuckles, and fingers.

Not only will they protect, but these glove coatings are available in different colors that also have hi-viz. Along with the use of different kinds of textures like crinkle and rough variants.

These palm-coated gloves provide similar comfort to knit gloves. To know more about palm-coating have a look at this video!

What’s your Grip?

These tough coatings will give a perfect experience for handling tough and materials filled with grease and chemicals. These gloves will enhance durability, chemical resistance, and even cut protection.

Many coatings can be used on knit gloves which are as follows:

Latex

Nitrile

Foam Nitrile

PVC

Neoprene

Zed coat

Micropore Nitrile

Polyurethane (PU)

Now, let us have a brief look at all these types of coating.

Latex Coated Gloves

Latex-coated gloves are soft and flexible. These soft gloves give a perfect grip and an anti-slip experience. Latex-coated gloves work well in all circumstances and temperatures, and they are a perfect choice for high temperatures too.

Latex gloves fall in the category of the most durable gloves, but you may experience low abrasion and oil resistance. Latex gloves can resist the use of alcohol and some categories of ketones, but they won’t work well for organic solvents and hydrocarbons.

Latex gloves are perfect to use in construction, masonry, and even landscaping.

Foam nitrile-coated gloves work well when it comes to oil handling and wet conditions. The foam nitrile coating gives an experience of a sponge that absorbs all the moisture. In this way, you can easily handle small parts, construction, and automotive handling.

However, foam nitrile coating is not ideal for liquids and adhesives because they may seep inside the gloves.

Nitrile Coated Gloves

Nitrile-coated gloves are perfect for general work because of their durability and robustness. The nitrile coating will prevent cuts, tears, and even abrasions. These gloves work well between -25 F and 350 F.

Nitrile-coated gloves are durable, but they will not provide a robust grip in oily and wet conditions compared to micropore nitrile work gloves.

Micropore Nitrile Gloves

Micropore nitrile gloves work best for oily grip. These gloves consist of different suction cups which absorb all the oil and liquid providing a firm grip.

This coating doesn’t work well with adhesives, but the outcome is highly abrasion-resistant.

Polyurethane Coated Gloves

Polyurethane-coated gloves come with the best stretch and flexibility. These gloves work well for delicate applications, and the coating offers flexibility.

Polyurethane-coated gloves are resistant to all kinds of liquids, including oil. It is also heat resistant, but these gloves are not recommended to use above 79 degrees celsius. These polyurethane gloves work perfectly well for aerospace, fine part handling, and even with assembly and inspection.

PVC Gloves

PVC gloves work the best with adhesives, and they are abrasion-resistant. The adhesives won’t stick on the gloves so that you can work without any hassle. These gloves are best when working with furniture, automotive assembly, and trim applications.

These PVC gloves are perfect to use within cold conditions, and these PVC gloves are flexible but not tactile with rubber products.

Zed Coat Gloves

Zed coat coating works the best with oil solvents, water, and abrasive punctures. It is also called the green monster due to its abrasive resistance.

The material used in Zed Coat gives excellent grip, the application of oil and wet applications. However, this zed coating does not work well with adhesives. You can use these gloves with aerospace, glass application, and even in the automotive industry.

Neoprene Coating Gloves

Neoprene coating gloves are synthetic rubber that also comes with chemical stability and heat resistance. These gloves are suitable for chemical-resistant and fire-retardant installations.

Neoprene coating will provide a dry, oily, and wet grip, but it has low resistance towards abrasion.

Final Verdict!

The palm coating works perfectly well for punctures, abrasion resistance, and oil resistance. You can select any glove according to your requirements as all of these gloves will give a comfortable experience while wearing them.

Looking for comfortable gloves should be your topmost priority so that there is no chance of removing these gloves and damaging your skin and hands.

Palm-coated gloves will become your new favorite with a long-lasting experience.

About us:

10053 Whittwood Dr, Suite 11284 Whittier, CA 90603

United States of America

(657-667-6227)