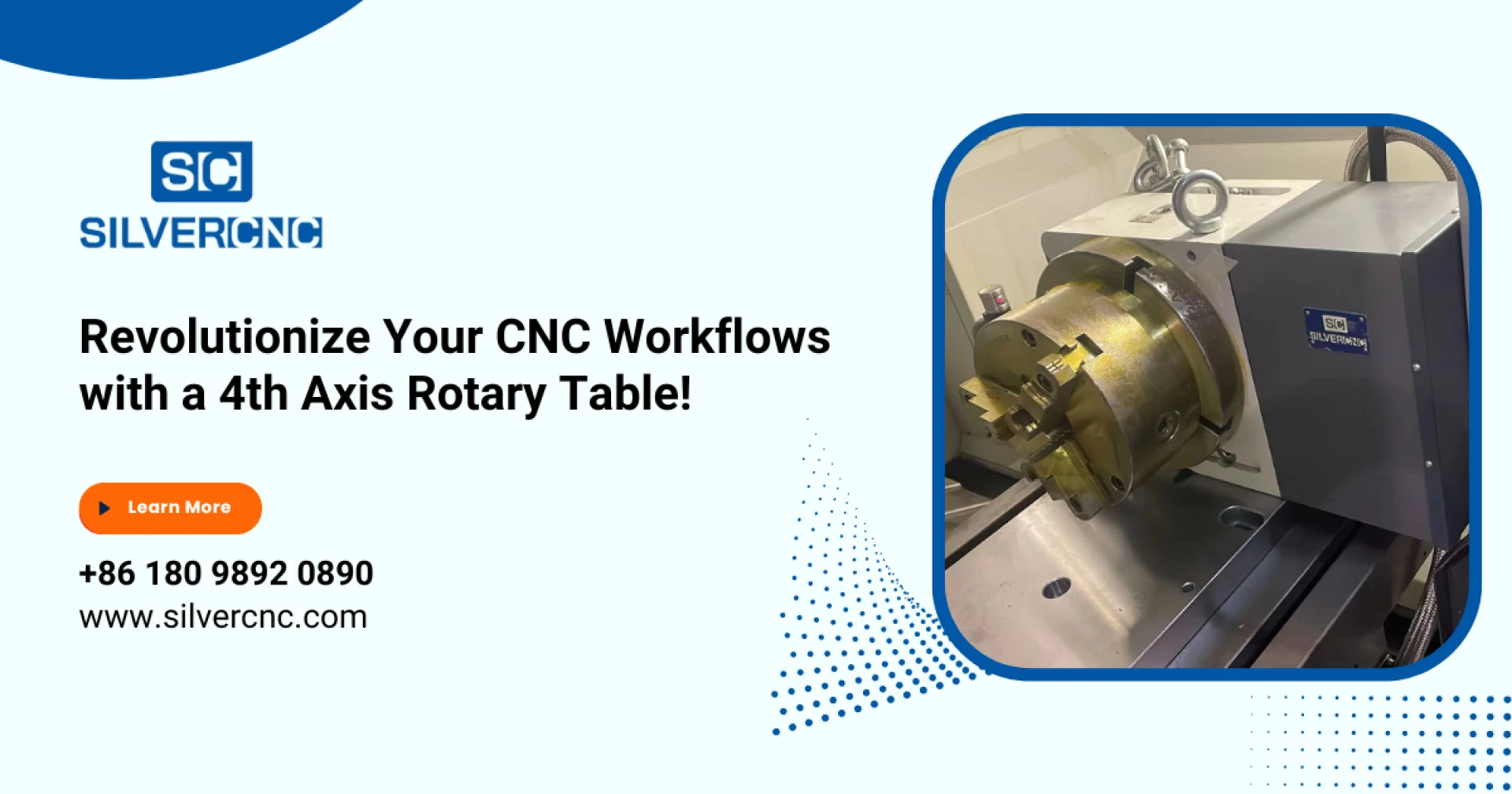

In today’s fast-paced manufacturing environment, CNC shops are constantly under pressure to deliver faster turnaround times, tighter tolerances, and increased part complexity—without sacrificing quality or profitability. So how can manufacturers overcome these challenges and elevate the productivity of their current CNC machines? The answer lies in a smart upgrade: the 4th Axis Rotary Table.

At Silvercnc, we specialize in high-performance CNC accessories that enable machinists and engineers to unlock new levels of precision and efficiency. Among these solutions, our 4th Axis Rotary Tables stand out as a pivotal tool that brings advanced capabilities to your existing 3-axis machining center—with minimal investment and maximum return.

By adding a rotary axis, you don’t just add motion—you introduce a whole new dimension to your machining strategy. Whether you’re a high-mix job shop, a prototype lab, or a production-focused manufacturer, integrating a 4th axis can:

- Reduce setup time drastically

- Improve overall machining accuracy

- Enable complex multi-sided part machining

- Increase throughput and reduce manual intervention

What is a 4th Axis Rotary Table?

A 4th Axis Rotary Table is a CNC accessory that adds rotational movement to standard 3-axis machines, enabling multi-side machining, greater precision, reduced setups, and faster production.

This is where the 4th Axis Rotary Table comes into play.

A 4th Axis Rotary Table adds a rotary motion—usually referred to as the A-axis—which enables the workpiece to rotate around a horizontal axis perpendicular to the Z-axis. This added degree of freedom turns a standard 3-axis machine into a more powerful and flexible tool capable of performing advanced machining tasks such as:

- Machining across multiple faces without refixturing

- Creating radial features (e.g., gears, holes placed on a circle)

- Contouring around predefined circular paths

- Helical milling and engraving

- Indexing for precise positioning

The rotary table is integrated with the CNC controller and can operate either:

- As a positioning axis (indexing mode), stopping at pre-determined angles for each operation

- As a fully interpolated axis (continuous or simultaneous motion), allowing for complex surface machining or 3D contouring

Top 6 Benefits of Using a 4th Axis Rotary Table

Adding a 4th axis to your CNC workflow isn’t just a minor upgrade—it’s a transformational change. Here's how your operation stands to gain.

1. One Setup, Many Faces

Without a 4th axis, machining different faces of a workpiece often requires multiple setups. Each time the part is removed and re-clamped, there's a risk of misalignment or tolerance stacking.

With a 4th Axis Rotary Table, you can:

- Machine 3, 4, or even all 5 faces (with angled head) of a part in a single setup

- Rotate the part to exact angular positions for precise machining

- Save hours of manual fixturing and measurement

This not only increases accuracy but also reduces labor costs and operator fatigue.

2. Enhanced Machining of Cylindrical and Round Parts

If your projects include shafts, gears, discs, or tubes, a rotary table is a game-changer. It allows the workpiece to rotate in relation to the cutting tool, which is essential when:

- Cutting keyways along shafts

- Drilling bolt hole patterns on round parts

- Engraving logos or text on cylindrical surfaces

- Performing radial slotting or fluting

Without a 4th axis, these operations would require specialized lathes or expensive 5-axis machines.

3. Reduced Cycle Time

Time is money, especially in CNC machining. A rotary table significantly reduces the non-cutting time by:

- Automating fixture rotation

- Minimizing the need for human interaction between cuts

- Allowing quicker toolpath transitions between features

When paired with CAM software optimized for 4-axis machining, the cycle time savings can be substantial.

4. Consistent Accuracy from One Job to the Next

With fewer part repositions and manual processes, a 4th axis setup ensures:

- Tighter tolerances

- More consistent part quality

- Reduced scrap rates

This is particularly beneficial in industries where microns matter—like aerospace, medical, and precision mold making.

5. Improved Machining Flexibility

A 4th axis instantly expands your machining capabilities. It becomes easier to:

- Take on new types of jobs

- Offer more complex parts to clients without outsourcing

- Adapt to varied workpiece geometries

This leads to increased shop versatility without needing five-axis machines.

6. Cost-Effective for Small and Medium Shops

Compared to upgrading to a 5-axis machining center, adding a 4th axis rotary table to your 3-axis machine is both easier and more affordable. With Silvercnc’s plug-and-play compatible rotary tables, even small to mid-sized shops can scale efficiently.

Popular Applications of 4th Axis Rotary Tables

Let’s examine real-world use cases where machinists are using rotary table to revolutionize their workflows:

Mold and Die Makers:

Machining parting lines, cores, and multiple cavities on a single setup to save time and improve mold symmetry.

Aerospace:

Precision drilling of fuel passages, turbine blade contouring, and compound-angle bores.

Medical Device Manufacturing:

Accurate rotational machining of orthopedic implants, surgical tools, and bone plates.

Automotive:

Camshaft profiling, hub drilling, and radial groove machining.

Job Shops:

Flexibly accommodate small-batch complex parts, custom prototyping, or fast-turnaround jobs.

Choosing the Right 4th Axis Rotary Table for Your Machine

There are various rotary tables on the market, but not all will suit your machine, application, or shop environment. Here's what you should consider:

Size and Load Rating

Select a rotary table that can support the weight of your largest workpieces and fixtures without compromising performance.

Drive System (Worm Gear vs. Direct Drive)

- Worm Gear: Reliable, precise, and suitable for most shops

- Direct Drive: Faster positioning with no backlash, ideal for high-speed applications

Indexing Accuracy and Repeatability

Choose a model that offers arc-second level precision to ensure tight tolerances.

Controller Compatibility

Ensure the rotary table integrates with your CNC controller. Silvercnc rotary tables support Fanuc, Siemens, Heidenhain, and others.

Mounting Flexibility

Tables with horizontal and vertical mounting options allow you to take on a wider variety of jobs.

Tips to Optimize 4th Axis Operation

Installing the rotary table is just the beginning—optimizing its performance involves the following best practices:

- Use Precision Fixtures: Combine self-centering vises, tailstocks, or custom jigs to enhance clamping stability

- Regular Maintenance: Clean and lubricate the table to maintain positioning accuracy

- Calibrate Often: Run regular checks on rotation and zero positioning

- Update Your Post-Processor: Ensure your CAM software is configured to handle 4-axis toolpaths correctly

- Start Small: Practice simple 4th axis indexing operations before diving into complex tasks

Silvercnc offers documentation, training, and support to help you master your rotary table from day one.

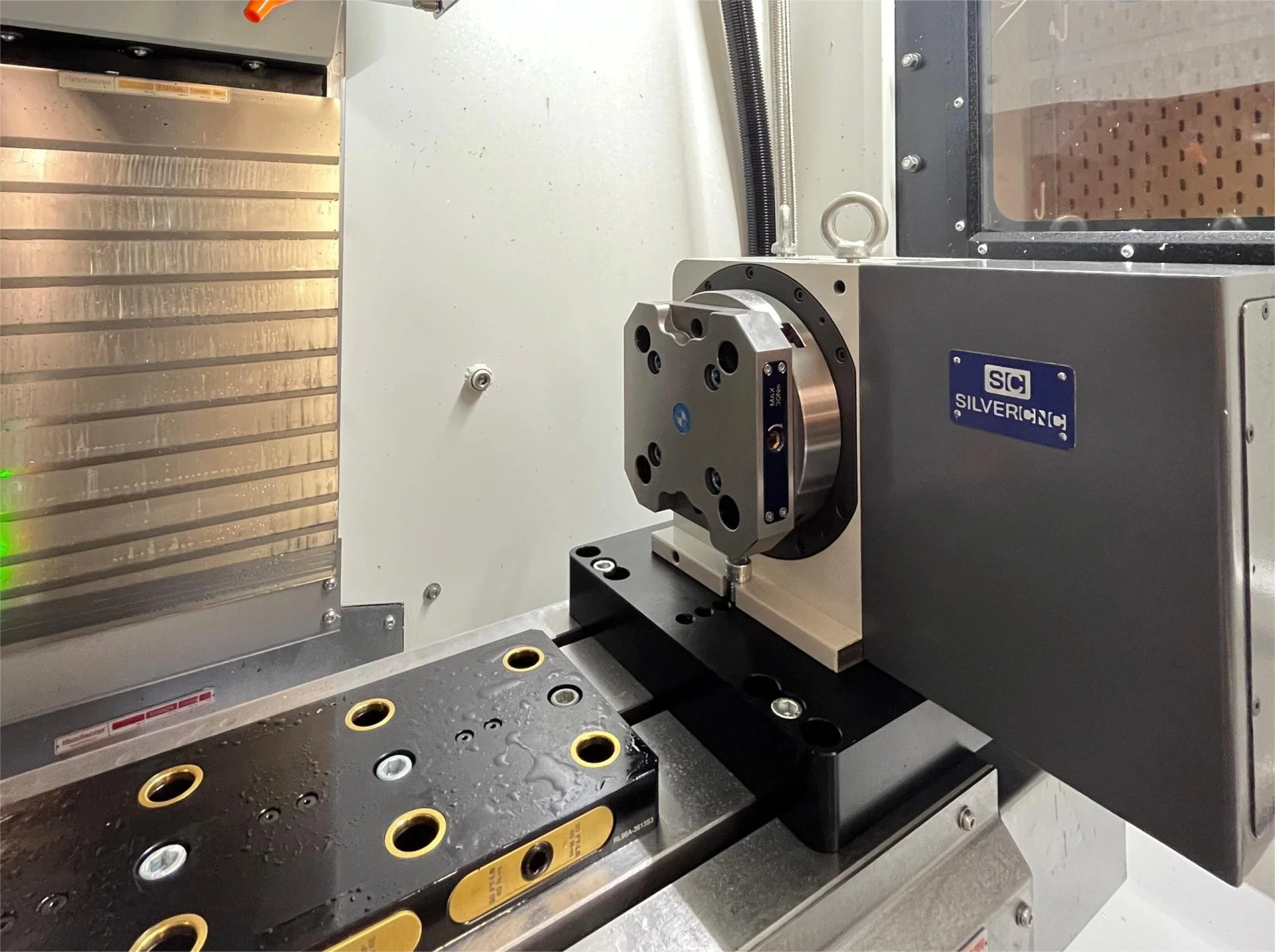

Why Choose Silvercnc for Your 4th Axis Rotary Table?

At SilverCNC, we’re committed to equipping machinists with tools that deliver both performance and peace of mind.

Our 4th Axis Rotary Tables are built with:

- High-grade hardened steel gears and bearings

- Precision indexing mechanisms with backlash elimination systems

- Sealed housings for coolant and chip protection

- Wireless, manual, and servo drive options

- Custom fixturing support and consulting services

Our team draws from decades of real-world CNC experience—helping you avoid costly mistakes and unlock real gains in productivity.

Revolutionize with Confidence

As part complexity rises and lead times shrink, standing out in the CNC machining world requires innovation—and the easiest, most impactful innovation you can make is adding a 4th Axis Rotary Table to your workflow.

With the ability to reduce setup time, boost accuracy, and tackle more challenging jobs, this single investment can redefine what your shop is capable of.

Frequently Asked Questions (FAQ)

Q1: Is a 4th axis difficult to install?

Not at all. Most modern CNC mills are designed for 4th axis integration. Silvercnc provides plug-and-play solutions and offers expert support for setup and calibration.

Q2: Can I use my CAM software with a 4th axis rotary table?

Yes. Popular CAM software—Fusion 360, Mastercam, SolidCAM, and others—support 4-axis toolpath programming. You'll need to configure your post processor accordingly.

Q3: Do I need a tailstock with a rotary table?

A tailstock is recommended when machining long or heavy workpieces. It supports the far end of the part, preventing deflection and ensuring balance.

Q4: What's the difference between a 4th axis and a 5th axis?

-A 4th axis (A-axis) adds rotation around the X-axis

-A 5th axis adds rotation around another axis (often the Y or Z) for more versatility in complex 3D surfaces

A 4th axis is more budget- and training-friendly while still offering major benefits.

Q5: Is a 4th axis rotary table worth the investment?

Absolutely. Most shops see ROI within months due to increased part complexity, reduced setups, and expanded service offerings.