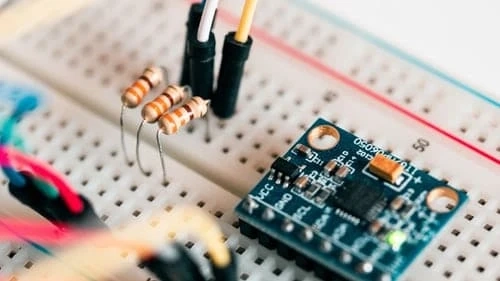

1. Selection of fixed resistors

There are many types of fixed resistors. Which material and structure to choose depends on the specific requirements of the application circuit.

High-frequency circuits should use non-wirewound resistors with small distributed inductance and distributed capacitance, such as carbon film resistors, metal resistors, and metal oxide film resistors.

Low-noise resistors should be used for high-gain small-signal amplifying circuits, such as metal film resistors, carbon film resistors, and wire wound resistors, instead of noisy synthetic carbon film resistors and organic solid resistors.

Wirewound resistors have high power, low current noise, high temperature resistance, but large size. Common wirewound resistors are often used in low-frequency circuits or as current limiting resistors, voltage divider resistors, bleeder resistors or bias resistors for high-power tubes. Wirewound resistors with higher precision are mostly used in fixed attenuators, resistance boxes, computers and various precision electronic instruments.

The resistance value of the selected resistor should be close to a nominal value of the calculated value in the application circuit, and standard series resistors should be preferred. The allowable error of resistors used in general circuits is ±5%~±10%. The resistors used in precision instruments and special circuits should be precision resistors.

The rated power of the selected resistor should meet the requirements for the power capacity of the resistor in the application circuit. Generally, the power of the resistor should not be arbitrarily increased or decreased. If the circuit requires a power resistor, its rated power can be 1 to 2 times higher than the power required by the actual application circuit.

2. Selection of fuse resistor

Fuse resistor is a resistor with protection function. The dual performance should be considered when selecting, and the resistance and power parameters should be selected according to the specific requirements of the circuit. It is necessary to ensure that it can quickly fuse when overloaded, but also to ensure that it can work stably for a long time under normal conditions. If the resistance value is too large or the power is too large, it will not play a protective role.

3. Selection of thermistor

There are many types and models of thermistors. Which thermistor to choose depends on the specific requirements of the circuit.

Positive temperature coefficient thermistors (PTC) are generally used in refrigerator compressor starting circuit, color picture tube degaussing circuit, motor overcurrent and overheating protection circuit, current limiting circuit and constant temperature electric heating circuit.

Thermistors commonly used in compressor starting circuits include MZ-01~MZ-04 series, MZ81 series, MZ91 series, MZ92 series and MZ93 series. The thermistor suitable for starting can be selected according to different types of compressors to achieve the best starting effect.

The degaussing thermistors used on color TVs and computer monitors include MZ71~MZ75 series. According to the working voltage (220V or 110V) of the TV and the monitor, the working current and the specifications of the degaussing coil, etc., the degaussing thermistor whose parameters such as the nominal resistance, the maximum initial current and the maximum working voltage meet the requirements can be selected.

Low-power PTC thermistors for current limiting include MZ2A~MZ2D series and MZ21 series, and PTC thermistors for motor overheat protection

There are MZ61 series of devices, and the models whose parameters such as nominal resistance, switching temperature, working current and dissipation power meet the requirements of the application circuit should be selected.

Negative temperature coefficient thermistors (NTC) are generally used in various electronic products for microwave power measurement, temperature detection, temperature compensation, temperature control and voltage stabilization. The appropriate type and model should be selected according to the needs of the application circuit. .

Commonly used NTC thermistors for temperature detection include MF53 series and MF57 series, and each series has multiple models (NTC thermistors of the same type and different models, with different standard resistance values) are available.

Commonly used NTC thermistors for voltage stabilization include MF21 series, RR827 series, etc. The thermistor voltage stabilization value and operating current can be selected according to the reference voltage value of the application circuit design.

Commonly used NTC thermistors for temperature compensation and temperature control are MF11~MF17 series. Commonly used NTC thermistors for temperature measurement and temperature control are MF51 series, MF52 series, MF54 series, MF55 series, MF61 series, MF91~MF96 series,

MF111 series and many others. NTC thermistors of MF52 series and MF111 series are suitable for the temperature range of -80℃~+200℃

The temperature measurement and temperature control circuit. NTC thermistors of MF51 series and MF91-MF96 series are suitable for temperature measurement and

Temperature control circuit. MF54 series and MF55 series NTC thermistors are suitable for temperature measurement and temperature control circuits below 125°C.

NTC thermistors of MF61 series and MF92 series are suitable for temperature measurement and temperature control circuits above 300°C. Choose temperature control heat

When using a sensitive resistor, pay attention to whether the temperature control range of the NTC thermistor meets the requirements of the application circuit.

4. Selection of Varistor

Varistors are mainly used in over-voltage protection circuits of various electronic products, and there are many models and specifications. The main parameters of the selected varistor (including nominal voltage, maximum continuous working voltage, maximum limit voltage, current capacity, etc.) must meet the requirements of the application circuit, especially the nominal voltage must be accurate. If the nominal voltage is too high, the varistor will not be able to protect against over-voltage, and if the nominal voltage is too low, the varistor will easily malfunction or be broken down.

5. Selection of photoresistor

When choosing a photoresistor, you should first determine the spectral characteristics of the photoresistor required in the application circuit. If it is used for various photoelectric automatic control systems, electronic cameras and light alarms and other electronic products, visible light photoresistors should be selected; if it is used for infrared signal detection and related automatic control systems in the fields of astronomy, military, etc., infrared should be selected. Photoresistor; if it is used in instruments such as ultraviolet detection, UV photoresistors should be used.

After selecting the unspecified type of photoresistor, you should also see whether the main parameters of the selected photoresistor (including bright resistance, dark resistance, maximum working voltage, apparent current, dark current, rated power, sensitivity, etc.) conform to Application circuit requirements.

6. Selection of Humidity Resistors

When choosing a humidity sensitive resistor, first select the appropriate type according to the requirements of the application circuit. If used for high humidity detection in household appliances such as washing machines and dryers, lithium chloride humidity resistors can be used; if used in air conditioners, humidistats and other household appliances for detection of medium humidity environments, ceramic humidity can be selected. Sensitive resistors; if used for weather monitoring, video recorder condensation detection, etc., you can use high molecular polymer humidity resistors or selenium film humidity resistors.

Ensure that the main parameters of the selected humidity resistor (including humidity measurement range, nominal resistance, working voltage, etc.) meet the requirements of the application circuit.

Summarized by Easybom.