In the dynamic landscape of global manufacturing, CNC (Computer Numerical Control) machining continues to be a driving force, shaping industries and pushing the boundaries of what's possible in precision engineering. Amidst this revolution, China remains at the forefront, continually refining its capabilities and offerings in CNC machining. In this article, we explore the latest advancements and trends in CNC machining in China, highlighting the key factors contributing to its continued prominence in 2024.

Unveiling the Latest Trends in CNC Machining in China

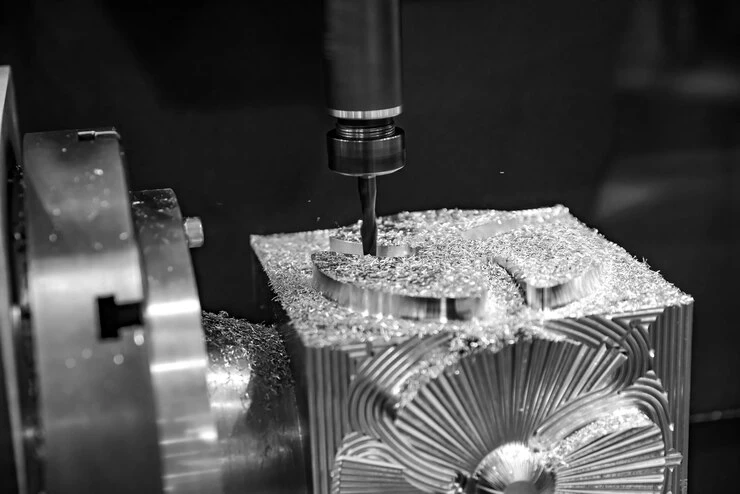

The Ever-Advancing Realm of CNC Machining

CNC Machining China has come a long way since its inception, with continuous technological advancements propelling it to new heights of efficiency, accuracy, and versatility. In 2024, the landscape of CNC machining is characterized by several notable trends:

Industry 4.0 Integration: As the fourth industrial revolution unfolds, China's CNC machining sector is embracing digitalization and connectivity at an unprecedented pace. Industry 4.0 technologies, such as IoT (Internet of Things), AI (Artificial Intelligence), and cloud computing, are being seamlessly integrated into CNC machining processes, leading to enhanced automation, real-time monitoring, and predictive maintenance.

Additive Manufacturing Synergy: While subtractive manufacturing processes have traditionally dominated CNC machining, the synergy between CNC machining and additive manufacturing (AM) is becoming increasingly pronounced. Chinese manufacturers are leveraging hybrid CNC-AM systems to combine the benefits of both technologies, enabling the production of complex geometries with greater efficiency and material utilization.

Enhanced Precision and Surface Finish: With advancements in tooling, machining strategies, and metrology techniques, CNC machining in China is achieving levels of precision and surface finish previously thought unattainable. Ultra-high-speed machining, adaptive control algorithms, and advanced tool coatings are enabling manufacturers to push the boundaries of what's achievable in terms of part accuracy and surface quality.

Key Factors Driving CNC Machining in China

1. Technological Leadership

China's commitment to technological advancement and innovation has propelled its CNC machining industry to global prominence. From investments in research and development to collaboration with leading technology providers, Chinese manufacturers are continuously pushing the envelope in terms of technological capabilities and performance.

2. Skilled Workforce

The availability of a skilled and adaptable workforce is a cornerstone of China's CNC machining success story. With a robust education system and vocational training programs tailored to the needs of the manufacturing sector, China boasts a vast talent pool of machinists, engineers, and technicians proficient in CNC machining operations.

3. Infrastructure and Supply Chain Efficiency

China's extensive industrial infrastructure and well-developed supply chains provide a solid foundation for the efficient operation of CNC machining facilities. From raw material sourcing to logistics and distribution, Chinese manufacturers benefit from a comprehensive ecosystem that facilitates seamless production processes and timely delivery of finished components.

4. Global Market Integration

In an era of globalization, China's CNC machining industry is deeply integrated into the global market, serving a diverse clientele spanning multiple industries and geographic regions. Leveraging its competitive pricing, fast turnaround times, and reputation for quality, China remains a preferred outsourcing destination for businesses seeking reliable CNC machining services.

The Path Ahead: Opportunities and Challenges

Looking ahead, the future of CNC machining in China appears bright, with ample opportunities for growth and innovation. However, the industry also faces certain challenges, including:

Rising labor costs: As wages in China continue to increase, manufacturers must explore automation and efficiency-enhancing measures to mitigate the impact on production costs.Quality control and compliance: Maintaining stringent quality control standards and ensuring compliance with international regulations remain ongoing priorities for Chinese CNC machining firms.Environmental sustainability: Addressing environmental concerns and implementing sustainable manufacturing practices will be essential for the long-term viability of China's CNC machining industry.In Conclusion:

CNC machining in China has evolved into a dynamic and technologically advanced sector, poised to meet the evolving needs of global manufacturing. By embracing innovation, fostering a skilled workforce, and adapting to changing market dynamics, Chinese manufacturers are well-positioned to maintain their leadership in CNC machining well into the future.