In many industries, from pharmaceuticals and manufacturing to aerospace and food processing, precise temperature measurement is crucial. Ensuring the accuracy of temperature sensors and instruments is essential for quality control, safety, and regulatory compliance. Central to this process is the use of a Temperature Reference Standard—a benchmark device or system that provides a highly accurate and stable temperature against which other temperature measurement devices can be calibrated.

What is a Temperature Reference Standard?

A Temperature Reference Standard is a device or apparatus that provides a known, reproducible temperature with a high degree of accuracy and stability. It serves as the fundamental baseline in temperature calibration laboratories and quality assurance processes. By comparing temperature sensors or thermometers to this standard, organizations can verify and adjust their instruments to maintain measurement integrity.

Temperature reference standards come in various forms, including fixed-point cells, standard platinum resistance thermometers (SPRTs), dry block calibrators, and liquid bath calibrators. Each type offers different levels of precision and suitability depending on the application.

Why is a Temperature Reference Standard Essential?

Accurate temperature measurement impacts many critical processes:

- Quality Control: Ensures products meet strict temperature specifications for safety and performance.

- Process Optimization: Helps maintain precise conditions for chemical reactions, manufacturing processes, or food storage.

- Regulatory Compliance: Many industries must adhere to standards set by bodies like ISO, ASTM, and FDA, which often require traceability to a recognized temperature reference.

- Reliability and Safety: Prevents equipment failure and hazards caused by incorrect temperature readings.

Without a reliable Temperature Reference Standard, temperature measurements can drift over time, leading to inaccurate data and potentially costly errors.

Types of Temperature Reference Standards

- Fixed-Point Cells

- Fixed-point cells use pure substances (such as the melting point of pure metals or the triple point of water) to establish highly accurate and reproducible reference temperatures. These cells are considered primary standards and are often used by national metrology institutes.

- Standard Platinum Resistance Thermometers (SPRTs)

- SPRTs are precision thermometers used as secondary temperature standards. They offer excellent accuracy and stability over a wide temperature range and are commonly calibrated against fixed-point cells.

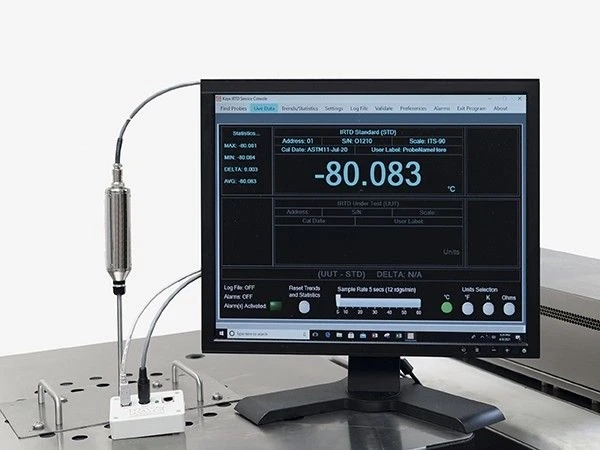

- Dry Block Calibrators

- These provide a stable temperature environment using a metal block that can be heated or cooled. They serve as practical, portable temperature reference standards for on-site calibration of sensors.

- Liquid Bath Calibrators

- Offering superior temperature uniformity, liquid bath calibrators use a fluid medium to maintain consistent temperatures. They are ideal for laboratory calibration where immersion and uniform temperature distribution are required.

How to Use a Temperature Reference Standard

The process of using a temperature reference standard typically involves:

- Stabilizing the reference device at the target temperature.

- Inserting the temperature sensor or instrument into the reference device’s measurement zone.

- Comparing the sensor’s reading to the known temperature provided by the reference standard.

- Adjusting the sensor or recording deviations to ensure accuracy.

Regular calibration using a reliable temperature reference standard ensures the accuracy and repeatability of temperature measurements.

Traceability and Calibration

An essential aspect of any Temperature Reference Standard is traceability—meaning its measurements can be traced back to internationally recognized standards maintained by national metrology institutes (e.g., NIST, PTB). Traceable calibration certificates provide documented proof of accuracy, which is critical for quality audits and regulatory compliance.

Applications Across Industries

Temperature reference standards are vital in numerous sectors:

- Pharmaceuticals: Ensuring the correct temperature in drug manufacturing and storage to maintain efficacy.

- Food Processing: Verifying temperatures during cooking, freezing, and storage to guarantee safety.

- Aerospace: Calibrating sensors used in extreme environments to ensure flight safety and performance.

- Manufacturing: Monitoring and controlling processes requiring strict temperature tolerances.

- Energy: Calibrating sensors in power plants and refineries for optimal performance and safety.

Future Trends in Temperature Reference Standards

Advances in technology are driving improvements in temperature reference standards:

- Miniaturization: Portable and compact reference standards enable on-site, real-time calibration.

- Automation and Smart Calibration: Integration with digital systems and IoT devices allows automated calibration and data logging.

- Improved Materials: New materials with better thermal stability enhance the accuracy and lifespan of reference standards.

- Enhanced Traceability: Greater global standardization ensures more uniform calibration across borders.

Conclusion

A Temperature Reference Standard is the cornerstone of accurate temperature measurement and calibration. Whether using primary fixed-point cells, SPRTs, or practical dry block and liquid bath calibrators, having a reliable temperature benchmark is critical to maintaining quality, safety, and compliance in various industries. Investing in proper temperature reference standards and regular calibration routines empowers organizations to achieve precision and confidence in their temperature measurements, ultimately supporting efficient and safe operations.