In the world of industrial mixing, where efficiency, precision, and reliability are paramount, there's a small yet crucial component that often goes unnoticed—the mixer seal. These unassuming seals play a vital role in ensuring that everything from food and beverages to chemicals and pharmaceuticals are mixed with precision and safety. In this article, we'll explore the world of mixer seals, their importance, types, and how they contribute to the smooth operation of industrial mixers.

Understanding Mixer Seals:

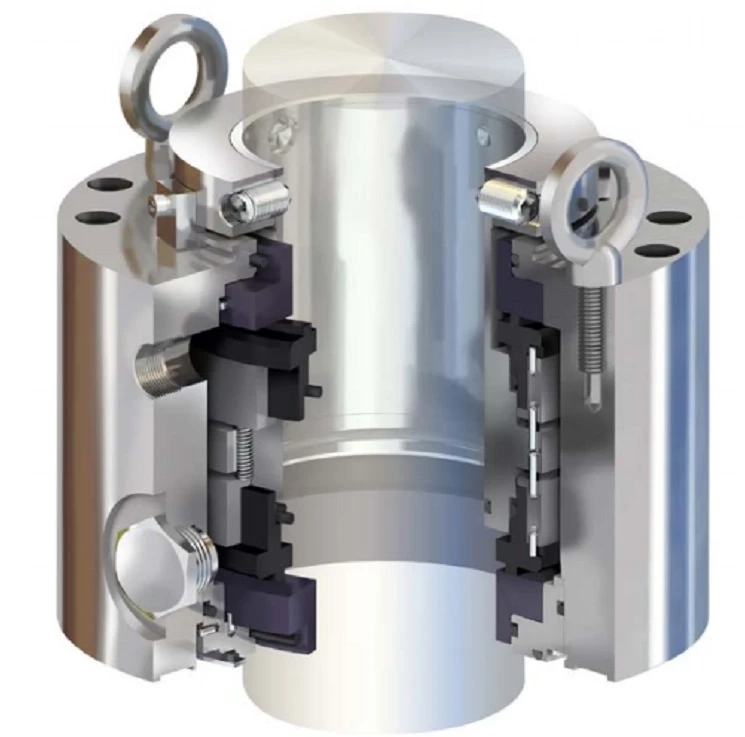

Mixer seals, also known as mixing seals or agitator seals, are mechanical seals specifically designed for use in mixing and agitating applications. These applications can range from simple blending in food processing to complex chemical reactions in pharmaceutical manufacturing. Mixer seals are engineered to provide a secure and leak-free environment for the mixing process, preventing contamination and ensuring product quality.

The Importance of Mixer Seals:

Containment: Mixer seals are essential for containing the contents of the mixing vessel. Whether it's a corrosive chemical or a sensitive pharmaceutical ingredient, preventing leaks and spillage is critical to safety and productivity.

Hygiene: In industries like food and pharmaceuticals, hygiene is paramount. Mixer seals help maintain a sterile environment, preventing external contaminants from entering the mixing process.

Product Quality: Mixer seals contribute to product quality by ensuring that ingredients are thoroughly mixed and that the final product meets the desired specifications.

Safety: Some mixtures can be hazardous if not properly contained. Mixer seals enhance safety by preventing leaks that could lead to accidents or chemical exposures.

Types of Mixer Seals:

Mixer seals come in various designs to suit different mixing applications. Here are some common types:

Single Mechanical Seals: These seals consist of two flat surfaces pressed together to create a seal. They are suitable for basic mixing applications.

Double Mechanical Seals: Double seals incorporate two sets of sealing faces with a barrier fluid in between. They are used in more demanding applications, providing an extra layer of protection against leaks.

Magnetic Mixer Seals: These seals use magnets to drive the mixer, eliminating the need for a traditional shaft and seal. They are ideal for applications where maintaining a completely leak-free environment is crucial.

Externally Pressurized Seals: These seals are designed for high-pressure applications. They use an external fluid source to maintain a pressure barrier between the seal faces.

Choosing the Right Mixer Seal:

Selecting the appropriate mixer seal is crucial for ensuring optimal performance and longevity. Consider the following factors:

Application: The type of mixer and the materials being mixed will influence the choice of seal. For example, food-grade seals are required in the food industry.

Operating Conditions: Temperature, pressure, and the characteristics of the mixing process must be considered. Some seals are better suited for high-temperature or high-pressure applications.

Product Compatibility: Ensure that the seal materials are compatible with the substances being mixed to prevent chemical reactions or contamination.

Maintenance: Consider ease of maintenance, as some seals may require more frequent servicing than others.

Maintenance and Troubleshooting:

Proper maintenance is essential to ensure that mixer seals continue to perform effectively. Here are some maintenance tips and troubleshooting guidelines:

Regular Inspections: Schedule routine inspections to check for wear and tear on the seal faces, springs, and elastomers. Replace any damaged components promptly.

Lubrication: Ensure that the seal is properly lubricated to reduce friction and heat generation.

Temperature and Pressure Monitoring: Keep a close eye on operating temperatures and pressures. Sudden spikes could indicate a seal problem.

Leak Detection: If you suspect a leak, perform a leak test using appropriate methods and equipment.

Professional Servicing: For complex seals and critical applications, consider having a professional service the seals to maintain their integrity.

Mixer seals may be small in size, but their significance in industrial mixing processes cannot be overstated. They are the unsung heroes that ensure the safety, efficiency, and quality of countless products we rely on every day. Understanding the different types of mixer seals, choosing the right one for your application, and implementing proper maintenance practices are essential steps in achieving seamless and reliable mixing operations. Whether you're in the food industry, pharmaceuticals, or any field that involves mixing, the role of mixer seals in your processes is indispensable.