The oldest kind of visual inspection uses the human eye to inspect products and materials in a production unit. Still, many manufacturing and medical industries use this method for detecting faulty products from the ground level. However, artificial intelligence is a new technology becoming more beneficial in various production facilities to provide industries with faster, cheaper, and superior automation. The deep learning approach of automation can significantly affect the understanding of visual inspection systems.

In this article, we will learn about the visual inspection system and how it benefits the industry today:

What is the visual inspection system, and what are its applications?

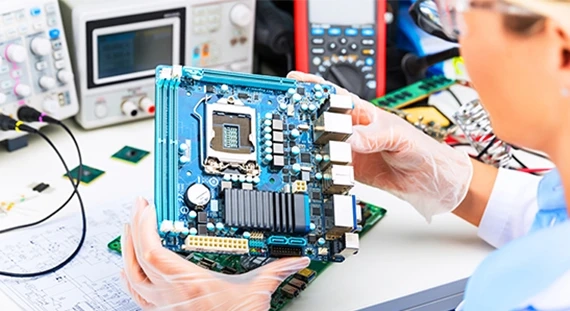

Visual inspection equipment is useful in the industrial world for evaluating products for quality control and maintenance facilities. It can also be used to inspect the inside and outside of storage tanks, pipes, pressure vessels, and a variety of other tools in the industry. Image-based inspection can be provided via visual inspection systems for a variety of industrial industry applications. These inspection procedures stay working and take place at regular periods. This sophisticated device assists you in inspecting your production line to detect even hidden defective products during production.

Visual inspections can be performed in accordance with your industrial procedure. It can assist you in identifying all of the tools, products, and materials, as well as determining which criteria trigger the inspection. Before adopting a visual inspection system in your company, you must develop clear guidelines to determine what constitutes a defect and how frequently you should set the inspection limit. This system includes multiple cameras as well as lighting. This system can thoroughly measure the parts and then verify them in the correct position. It not only recognizes the shape of parts but also sorts the parts at high speeds.

Where can we use the visual inspection system?

Reviewing an object with the human eye is the simplest yet most powerful method to find product defects. However, in the case of safety and quality control, the visual inspection system works like a gem.

Oil and gas Industry - To prevent losses, downtime, and expensive repairs, a reliable, efficient, and economical inspection became necessary in the oil and gas industry. With an advanced visual inspection system, you can constantly inspect the equipment and keep them in good functioning condition. These systems can help you to enhance the tool's safety from mining and fuel to power generation.Healthcare Industry- Visual inspections are crucial for patient health and safety. Inspecting tools after surgery and other medical devices before is necessary to prevent the risk.Food Industry- Inspection is an essential part of quality control in the food industry. Without a trusted inspection system, it can lead to expensive errors and a low reputation of your products in the market; that’s why these systems majorly impact the food industry.Manufacturing Industry- if your industry manufactures cars, pharmaceuticals, or even semiconductors, a quality and efficient visual inspection system helps you to discover the assembly and cosmetic defects. Infrastructure Industry- For public safety, it is necessary to determine the potential issues. A visual inspection system provides efficient attention to minor details while inspecting roads and bridges.Why do we need the Visual Inspection System?

The key roles of this system are improving your products' quality and automating the inspection procedures. Proper inspection is necessary for the industry, and you can choose the right system as per your production requirements. Here are a few reasons to purchase a visual inspection system:

Higher Quality- A inspection system helps you to improve the process, planning, material procurement, and other complex jobs that will lead to a better quality of your products. It also increases the overall productivity of your business. Safety- Visual systems can easily identify foreign material and other contaminants that can penetrate packages and compromise the quality. They can cross-contamination so it won’t cause allergies issues for consumers. With these systems, you can achieve the full peace of mind that you are providing safe and quality products to your consumers. It will also help you to save your business from any legal trouble. Useful sensors- These inspection systems come with advanced industrial sensors to determine even a minor change in your system.Higher accuracy- A visual inspection system eliminates inaccuracy and provides higher-level accuracy results. Reduce the time and cost- A quality inspection system requires less time to inspect the products and provides you with speedy quality checks. It will maintain the production rate and higher productivity. Additionally, a visual inspection system can discover the defect early to reduce wastage and save you a lot.Wrapping up!

The visual inspection components can recognize various product shapes, efficiently measure parts, and analyze whether parts are in the correct position. These systems allow you to conduct complete quality control purposes. So, if you need a high-quality visual inspection system, Resion is a leading company that can provide you with an accurate solution for your industry. They have a team of industry experts and financial analysts who work diligently to develop these systems to help you to fix issues and improve the overall quality of your products. So call us at 514-742-6300 to learn more about our services!

0