In today’s manufacturing and woodworking industries, precision and efficiency are critical to success. Among the most reliable tools available are PCD tooling and router cutters, both of which provide superior performance, durability, and flexibility. At Saws and Cutting Tools Direct, we specialize in offering these high-quality tools to meet the needs of professionals across woodworking, plastics, composites, and more.

Understanding PCD Tooling

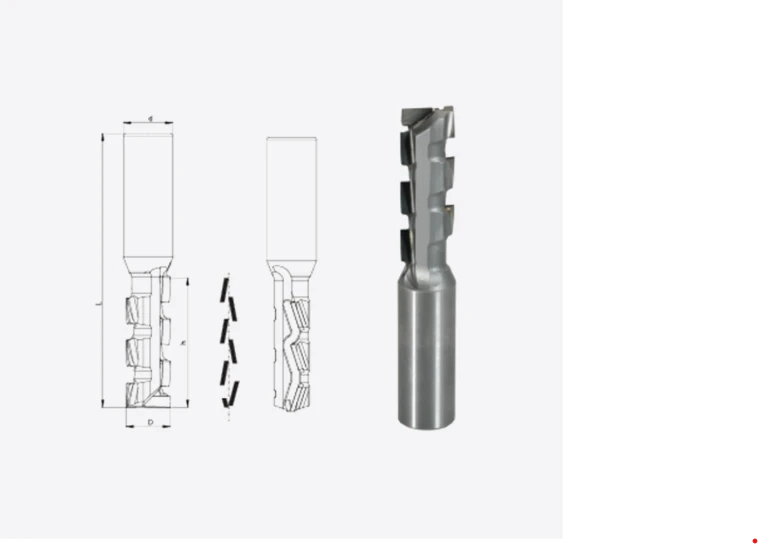

PCD tooling refers to tools that incorporate Polycrystalline Diamond (PCD), one of the hardest known synthetic materials, as the cutting edge. This makes PCD tools exceptionally durable and capable of producing high-precision results.

Benefits of PCD Tooling:

- Exceptional durability: Outlasts carbide tools by up to 50 times.

- Superior surface finish: Reduces the need for secondary finishing.

- Heat resistance: Maintains performance even at high cutting speeds.

- Cost savings: Though the upfront cost is higher, reduced tool replacement makes it economical long-term.

Industries that require precision and consistency, such as aerospace, automotive, and woodworking, rely heavily on PCD tools for their demanding applications.

The Role of Router Cutters

Router cutters are versatile cutting tools designed for shaping, trimming, and profiling a wide variety of materials. They are essential for both small workshops and large-scale production facilities.

Benefits of Router Cutters:

- Versatile applications: Suitable for woodworking, laminates, plastics, and composites.

- Precision cutting: Delivers sharp, clean edges with minimal waste.

- Variety of profiles: Available in straight, round-over, V-groove, and custom designs.

- Ease of use: Ideal for both manual routers and CNC machines.

Router cutters allow manufacturers and craftsmen to create detailed designs while maintaining consistent quality.

Combined Benefits of PCD Tooling and Router Cutters

When used together, PCD tooling and router cutters offer unmatched advantages for businesses focused on quality and efficiency.

- Enhanced precision: PCD edges ensure router cutters maintain accuracy over time.

- Extended lifespan: Tools last longer, reducing downtime and replacement costs.

- Increased productivity: Faster cutting speeds without sacrificing quality.

- Consistent finishes: Smooth surfaces that require little to no extra sanding or polishing.

This combination provides an edge in competitive industries where efficiency and quality are non-negotiable.

Applications in Different Industries

The use of PCD tooling and router cutters extends across several industries:

- Woodworking: Cabinets, flooring, and furniture production.

- Aerospace: Cutting lightweight but strong composite materials.

- Automotive: Precision work on dashboards, panels, and interior trims.

- Plastics & composites: Efficient cutting of laminates, MDF, and carbon fiber.

Their adaptability makes them indispensable in modern manufacturing.

Why Choose Saws and Cutting Tools Direct?

At Saws and Cutting Tools Direct, we provide PCD tooling and router cutters designed to deliver outstanding performance.

Why Trust Us?

- Wide selection: Tools available for all types of cutting applications.

- Quality focus: Built with premium materials for long-lasting use.

- Expert support: Guidance to help you choose the right tools.

- Affordable pricing: Competitive rates without compromising quality.

- Trusted reputation: Known for reliability in the cutting tools industry.

Final Thoughts

The benefits of using PCD tooling and router cutters are clear: enhanced durability, precision, and efficiency. Whether you’re a small workshop or a large industrial manufacturer, these tools ensure consistent quality and cost savings over time.

With Saws and Cutting Tools Direct, you gain access to high-quality cutting tools that help you work smarter, faster, and more efficiently. Investing in the right tools today means better results and long-term value tomorrow.