Offset printing is a well-liked printing technique used for various purposes, including books, periodicals, packaging, and advertising materials. The process entails transferring ink from a printing plate to a rubber blanket, which prints the substrate with the inked message. This method enables reliable, high-quality printing at a reasonable price. Various Offset Printing parts are needed to obtain a perfect result.

What Is A Printing Machine Cylindrical Jacket?

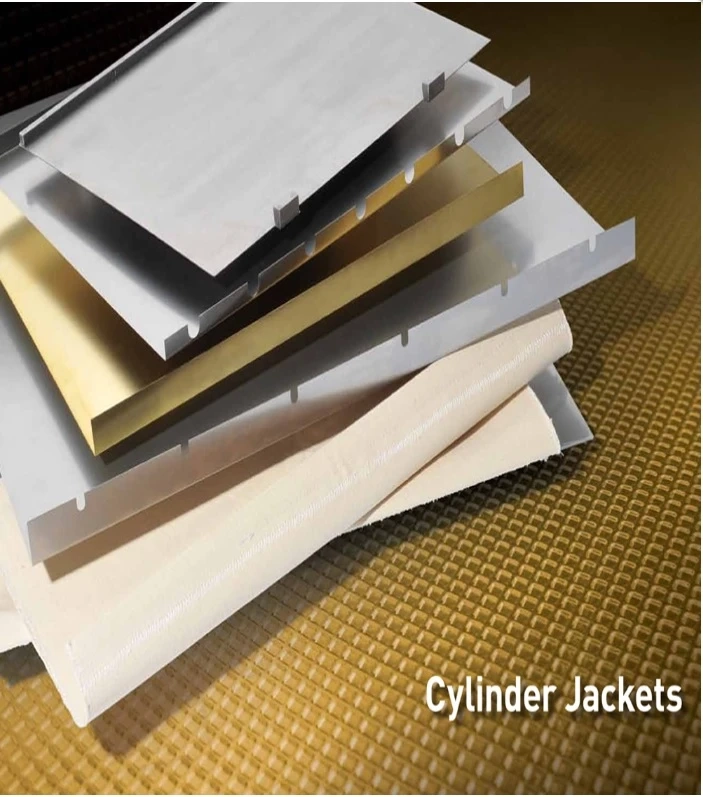

A printing machine cylinder jacket is one of the most important offset printing parts. A rubber-coated sleeve fits over the metal cylinder in an offset printing press. The jacket gives the printing plate a uniform, smooth surface to touch, resulting in precise and reliable ink transfer to the paper. The rubber layer also aids in absorbing any flaws in the cylinder surface that can smear or cause the printed image to be out of alignment.

The cylinder jacket enhances the quality of the printed picture and protects the cylinder from damage, extending the machine's lifetime. Ultimately, offset printing relies on the machine's cylindrical jacket to produce high-quality prints reliably and effectively.

Why Is A Printing Machine Cylindrical Jacket Necessary For The Printing Process?

All offset printing parts are necessary for the printing process. The cylinder jacket is one of them. First and foremost, the jacket gives the printing plate a smooth and even surface to touch, ensuring that the ink is applied to the paper precisely and uniformly. The rubber layer on the jacket also aids in absorbing any flaws in the cylinder's surface, such as scratches or dents, that may otherwise smear or cause the printed image to be out of alignment.

The Printing Machine Cylinder Jacket enhances the print quality and shields the cylinder from deterioration. Without the jacket, the cylinder's metal surface would be constantly subjected to friction and pressure from the printing process, which might eventually cause distortion or damage. The jacket contributes to an equal pressure distribution throughout the cylinder surface, lowering the possibility of damage and extending machine life.

How To Maintain A Printing Machine Cylinder Jacket?

Proper maintenance of the printing machine cylinder jacket is essential for ensuring an offset printing machine's smooth and efficient operation. Here are some tips for maintaining the jacket:

Regular Cleaning: The cylinder jacket should be cleaned regularly to remove any ink, dust, or debris that may accumulate on the surface. This can be done using a soft cloth or brush and a gentle cleaning solution.Inspect for Damage: The cylinder jacket should be inspected regularly for signs of wear and tear, such as cracks, tears, or bulges. Any damaged areas should be repaired or replaced promptly to avoid compromising the quality of the printed image.Check for Slippage: The connection between the cylinder jacket and the printing machine should be checked regularly to ensure that the jacket is securely attached and not slipping or shifting during printing.Use the Right Tools: When removing or installing the cylinder jacket, use the appropriate tools and techniques to avoid damaging the rubber coating or the cylinder itself.Store Properly: When not in use, the printing machine cylinder jacket should be stored in a cool, dry place, away from direct sunlight and sources of heat or moisture.