Imagine walking into your business kitchen and discovering your cool room has lost its cool. The stock is dripping with sweat, the temps are through the roof, and your business will pay the cost. It's every tradie's worst dream, isn't it? Business owners attempt to muddle along with a little bit of DIY thinking that will suffice. However, overlooking crucial warning signals can lead to disastrous failure and enormous losses. If you have a cool room crisis, you should know when to seek quality cool room repair services. In this guide, we will walk you through identifying emergencies, repairing typical breakdowns, understanding the risk of delay, and identifying when DIY is unacceptable. We will advise you on keeping your cool room in operation and your business secure.

Identifying urgent cool room issues

What would you do if a cool room stopped working?

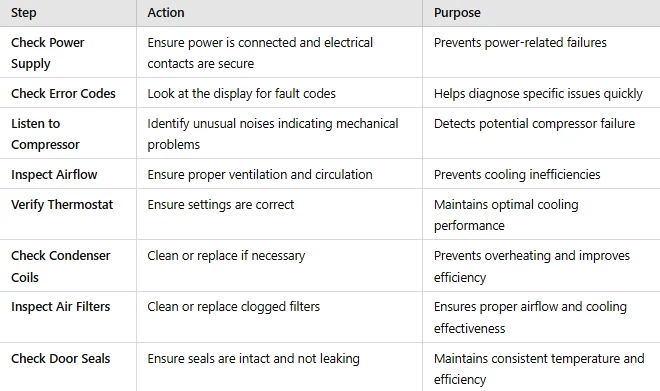

Knowing the first steps to take when a cool room breaks down assists in reducing damage and facilitating prompt action. Start by checking the power supply on the ground, ensuring the electric connection. Check the circuit breakers for tripping and reset any tripped switch. Check for unusual noises, which may be an indication of mechanical faults. Secondly, request the emergency service of a professional technician, asking for professional assistance. Knowledge of these steps facilitates quick response.

How do I know if my cool room needs immediate repair?

Immediate fault observation prevents substantial loss and helps you maintain your stored products. Be aware of sudden temperature increases, which can indicate a cooling system malfunction. Check for over-formation of ice, which may indicate airflow or defrost malfunctions. Smell unusual odours, which can indicate refrigerant leaks or electrical faults. Observe water leaks, which may imply drainage or condensation issues. These suggest that they must be repaired forthwith to avert further damage.

- Inspect power supply, check circuit breakers, and observe unusual noises, facilitating quick response.

- Summon an expert professional for quick emergency service, which guarantees an expert touch.

- Unusual temperature rises, icing, unusual odours, and water leaks suggest immediate repair, emphasising the situation's urgency.

- These signs suggest major breakdowns requiring urgent fixing to prevent further damage.

Troubleshooting common cool room failures

How to fix a cool room?

Knowing how to troubleshoot daily helps diagnose minor problems and avoid significant problems. Verify the thermostat readings and set them to the right. Examine the condenser, coils, and dust and wipe off dust and debris. Replace unclean air filters so clean airflow exists. Seal door gaskets for leaks and replace or fix them to seal. Following these steps assists with simple maintenance.

What are the first steps to take when a cool room malfunctions?

Understanding the risks of delaying cool room repairs

What happens if I don't fix my cool room right away?

Knowledge of the possible effects makes it simpler to value the need to take care of cool room problems on time to avert enormous losses. Food goes bad, resulting in loss of funds and wastage of stock. Temperature-sensitive inventory is spoiled, compromising product quality. Power consumption rises, contributing to higher operation expenses. Equipment life is reduced, necessitating early replacements. Operations in business are shut down, disrupting workflow and incomes. Being conscious of these dangers makes it simple to act early.

What are the consequences of ignoring cool room problems?

Identifying the long-term consequences helps realise the significance of preventive maintenance and early repairs, which protects your business. Economic losses, including product spoilage and business disruptions, are incurred. Customer complaints are increasing, impacting business reputation. Regulatory fines are incurred for failing to achieve safety levels. The business reputation is affected, and customer loyalty and trust decrease. Safety risks occur, endangering workers and customers. Identifying these consequences aids in prevention.

- Food wastage, stock rotation, and extra energy use results, which signals an emergency.

- Equipment life is reduced, and company operation stops, affecting revenue.

- Financial loss, customer complaints, and administration fines come into play, which signals consequences.

- The business's reputation is compromised, and security risks are taken, affecting future viability.

When DIY repairs are not enough

Preventative measures to avoid emergency repairs

How do you service a cold room?

Regular maintenance prevents breakdown repairs and prolongs the longevity of your cool room, reducing downtime. Sustained clean-up of condenser coils preserves heat transfer efficiency. Check for door seals to prevent air escape and energy loss. Check thermostat calibration for optimum temperature control. Check refrigerant levels to maintain system functionality. Schedule professional maintenance to catch problems at an early stage. Awareness of these steps motivates prevention.

How often should a cold room be serviced?

Knowing the proper service interval facilitates maximum performance, avoids breakdown, and maintains business continuity. Cool rooms are serviced every 3-6 months, the norm for regular maintenance. The usage-based service interval varies according to operational needs. Periodic checkups prevent serious problems and catch issues early. Knowing these schedules facilitates maintenance.

- Clean condenser coils regularly, check door seals, and ensure thermostat calibration, facilitating prevention.

- Check refrigerant levels and arrange for professional maintenance to avoid problems, guaranteeing longevity.

- Cool rooms are serviced every 3-6 months, depending on operation and conditions, to be arranged conveniently.

- Preventive inspection prevents major problems and increases lifespan, guaranteeing reliability.

When should I call for emergency cool room repairs?

What constitutes an emergency cool room repair?

Diagnosing emergency conditions aids in prompt response and averts massive losses, safeguarding your business. Total failures of the system, halting all cooling activities. Sudden temperature rise, compromising stock spoilage. Leaks of refrigerants causing safety risks. Electrical faults, resulting in system shutdown. Failure of compressors, causing instantaneous loss of temperature. Diagnosis of these conditions aids in prompt response.

When should I call for 24/7 cool room repair services?

Awareness of how to order 24/7 services minimises downtime and safeguards critical inventory so the business can operate without interruption. Order 24/7 services during working hours to prevent downtime discontinuity. Order 24/7 out-of-hour breakdowns for instant response. Order 24/7 protection of stock for safekeeping in case of perishable products. Order 24/7 necessary shutdown of life-sustaining systems to save heavy losses. Establishing such requirements in advance assists in rapid action.

- Complete system breakdowns, sudden temperature increases, and refrigerant leaks are emergencies and defining urgency.

- Electric failure and compressor breakdown also fall under emergencies, which should be addressed immediately.

- Call for business hours, 24/7 services and after-hours breakdowns, assuring response.

- Call for immediate stock protection and critical system shutdowns to avoid losses, assuring continuity.

Conclusion

Knowing when to request emergency cool room repairs is essential to safeguard your business, avoid massive losses, and maintain operational effectiveness. By identifying priority problems, troubleshooting frequent breakdowns, and understanding when DIY is not an option, you can keep your cool room energy efficient and functional, reducing downtime. Do not wait for an utter breakdown; respond immediately to repair issues and keep your equipment in working condition, protecting your investment. Dealt with experienced professionals to ensure your cool room remains in working order, your business runs smoothly, and you get quality service. Spend money on immediate repairs and maintenance in anticipation of possible malfunctions to protect your stock and business reputation and make it run long-term.