When it comes to PCB assembly, you know that quality isn\'t just a buzzword; it\'s the cornerstone of reliability and performance in electronic devices. Imagine the consequences of overlooking quality control measures – the ramifications could be far-reaching. So, why does quality matter so much in PCB assembly? Let\'s explore how it shapes the landscape of electronic manufacturing and why cutting corners is simply not an option.

Importance of Quality Control

Quality control is crucial in PCB assembly to ensure the reliability and functionality of electronic devices. When choosing a PCB assembly company, the importance of quality control can\'t be overstated.

By implementing rigorous quality control measures throughout the assembly process, a reputable PCB assembly company can detect and rectify any potential issues before they impact the final product. This meticulous attention to detail helps in guaranteeing that the assembled PCBs meet the required specifications and standards.

Without stringent quality control procedures in place, the risk of defects, malfunctions, or failures in electronic devices significantly increases. Therefore, selecting a PCB assembly company that prioritizes the importance of quality control is essential for ensuring the overall performance and longevity of electronic products.

Impact on Reliability and Performance

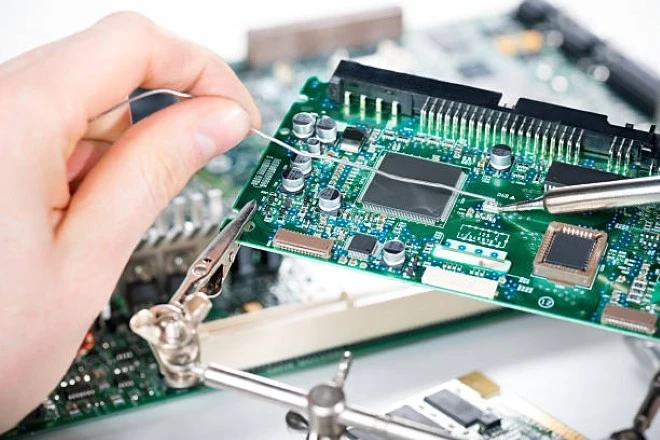

The meticulous quality control measures implemented in PCB assembly directly impact the reliability and performance of electronic devices. When a PCB assembly manufacturer ensures that each component is properly soldered, and all connections are accurate, it significantly reduces the chances of malfunctions or failures in the circuit board.

By maintaining high standards throughout the printed circuit board assembly process, the overall quality of the electronic device is enhanced, leading to improved longevity and consistent performance. Quality assurance at every stage of PCB assembly, from initial component placement to final inspections, plays a crucial role in determining the reliability and functionality of the end product.

Trusting a reputable PCB assembly manufacturer can make a substantial difference in the performance of your electronic devices.

Cost Savings Through Quality Assurance

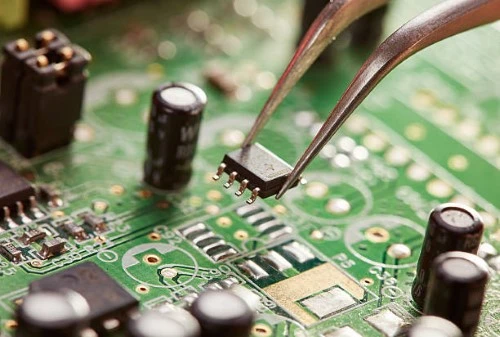

Implementing rigorous quality assurance measures in PCB assembly can lead to significant cost savings in the long run. By ensuring that components are correctly placed, soldered, and inspected, you can prevent costly errors and rework down the line.

Catching defects early through thorough testing and inspection processes can help avoid expensive recalls or customer returns. Additionally, investing in high-quality materials and equipment upfront may have a higher initial cost but can result in lower failure rates and maintenance expenses over time.

Proper training for assembly staff in quality control practices can also reduce the likelihood of mistakes that could lead to costly production delays. Ultimately, prioritizing quality assurance in PCB assembly can translate into tangible financial benefits for your business.

Enhancing Functionality With Precision Assembly

Maximize the performance of your PCBs by focusing on precision assembly techniques that enhance functionality and reliability. Utilizing precise soldering methods, such as surface mount technology (SMT) and through-hole technology, ensures components are securely attached, leading to improved signal integrity and reduced risk of short circuits.

Implementing automated optical inspection (AOI) and X-ray inspection during assembly detects any defects or soldering issues early on, guaranteeing a higher level of quality and performance. Additionally, using advanced testing procedures like in-circuit testing (ICT) and functional testing verifies the functionality of the assembled PCB, allowing for corrections before the final product is delivered. Navigate to this website to find out printed circuit board assembly service.

Customer Satisfaction and Brand Reputation

To build strong customer satisfaction and enhance brand reputation, prioritize delivering PCB assemblies that consistently meet or exceed expectations. By focusing on quality in every step of the assembly process, you ensure that customers receive reliable and high-performing products.

Meeting deadlines, providing excellent customer service, and offering solutions to any issues that may arise are crucial aspects of maintaining customer satisfaction. When customers are happy with the products they receive, they\'re more likely to become repeat buyers and recommend your brand to others.

Positive customer experiences not only lead to increased loyalty but also help in building a reputable brand image in the electronics industry. Prioritizing quality in PCB assembly is key to fostering customer satisfaction and strengthening brand reputation.

Competitive Edge in the Electronics Market

Maintain a competitive edge in the electronics market by consistently innovating your PCB assembly processes and staying ahead of industry trends. By embracing new technologies, such as automated assembly equipment and advanced inspection techniques, you can enhance the efficiency and quality of your production.

Implementing lean manufacturing principles can streamline your processes, reducing lead times and costs while improving overall product quality. Additionally, staying informed about the latest advancements in materials and components allows you to offer cutting-edge solutions to your customers.

Long-Term Benefits of Quality PCB Assembly

Investing in high-quality PCB assembly processes offers substantial long-term benefits for your electronics manufacturing business. Quality assembly leads to enhanced reliability and durability of your electronic products, reducing the need for frequent repairs or replacements.

This results in increased customer satisfaction and loyalty, as they trust in the longevity of your products. Moreover, high-quality PCB assembly helps in minimizing costly recalls and warranty claims, saving your business both time and money in the long run.

Conclusion

In PCB assembly, quality control is crucial for ensuring reliability, performance, and customer satisfaction. By prioritizing quality assurance, you can save costs, enhance functionality, and build a strong brand reputation.

With precision assembly and rigorous quality checks, you gain a competitive edge in the electronics market and set yourself up for long-term success. Remember, quality matters – invest in it for the best results in PCB assembly.