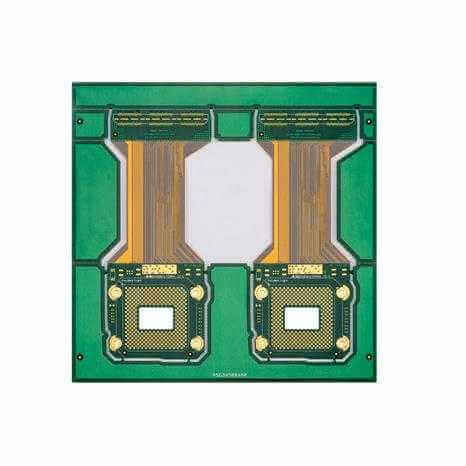

More benefits are offered to the user by quick turn rigid flex pcb than conventional wooden boards and flex circuits. This mix of stiff and flexible circuits enhances performance and quality control. Rigid-flex boards are more common than ever inside various gadgets. Others are big and intricate, while others are little and simple. Rigid-flex boards have many uses and are a favorite in the industry since they can be utilized to solve many common problems.

Manufacturing

A type of PCB fabrication known as “rapid turn” enables manufacturers to complete projects or fill orders more quickly than usual without sacrificing quality. According to the complexity of the board being produced, in terms of design specifications, surface finish, number of layers or board stack up, mounting techniques (SMT or Through hole), and lamination, the entire PCB fabrication and assembly process can be completed in a concise amount of time.

Reason to manufacturing

Prototype PCBs and low-volume production were the first targets of the quick turn rigid flex manufacturing method. However, quick-turn PCBs are now used in every stage of product development, from basic idea design and functional prototypes to putting out the completed product to the market quickly due to the electronics industry's rapid evolution—two main advantages of quick-turn PCB assembly.

The most crucial advantage is that it is time saving. Because of the quick turnaround time it provides, users have a competitive advantage in the market today.

Benefit

Production of quick turn rigid flexoften goes quite quickly. Usually, production is finished in a day or two. Some manufacturers promise delivery within the following 24 hours of placing an order. PCB prototyping is appropriate for a quick-turn PCB. This is because quick turn boards are frequently finished quickly. Additionally, these boards are perfect for designers who are developing fresh concepts. Saving money is another significant advantage of quick-turn rigid-flex PCB. Each circuit board costs less to produce because production moves quickly.

Convenience with repairs and upkeep

Flex-rigid boards are easier to repair and maintain than their equivalents due to an exposed signal channel and straightforward design. Because of its 3D form, it can be bent and folded to enable repair technicians to reach and fix everything they need to.

There are no tricky board-to-board connectors, and debugging and cleaning the circuit is straightforward. This makes finding and fixing board flaws during routine maintenance simple. Additionally, all parts on a rigid-flex board are identified, unlike conventional circuits, which simplify assembling and dismantling.

Key Takeaways

The fastest way to produce large quantities of printed circuit boards with a very low likelihood of product flaws is through a flexible pcb manufacturer, which has won widespread industry praise for its efficiency. Research, design, prototype fabrication, testing, and pre-production batches are all part of a standardized process that results in complete production assembly while saving time and money.

For More information visit us: https://www.x-pcb.com/product/rigid-flex-pcb-manufacturer/