Since the fundamental limit of ABREX is to give assurance from scratched territory, in this way we try to manufacture precision fabricated Abrex 600 Plates, which are extensively known for their positive conditions like high insurance from effect, weld breaking point, handiness, and significantly more. One progressively included piece of breathing space that goes with the usage of ABREX 600 sheets and plates is that the greatness of the fundamental part reduces enormously, which shows to be of authentic help with truly grinding working conditions. This associates in growing the future of the mechanical parts related with these sheets and plates.

At Vandan Steel & Engg. co., we attempt to cling ourselves to all the fundamental worldwide models and benchmarks of collecting, to retreat the entire methodology. In addition, the amassing of Abrex 600 Abrasion Resistant Plates and Sheets, is done in proximity of all the skilled and experienced partners, who work relentlessly towards collecting the best grouping of things for our customers.

Our entire workplace is outfitted with the best extent of equipment and mechanical assembly, which makes the age of Abrex 600 Wear Resistant Plates and Sheets especially smooth and mix-up free. All these Abrex sheets and plates are caused available to our customers at a completely moderate an incentive to go.

Abrex 600 plates have a lot of characteristics given by solidified steel make it a convincing candidate in materials decisions. Solidified steel is subsequently low carbon steel which contains chromium at extra by weight. It is the extension of chromium that gives the steel of its novel flawless, spoil restricting properties.

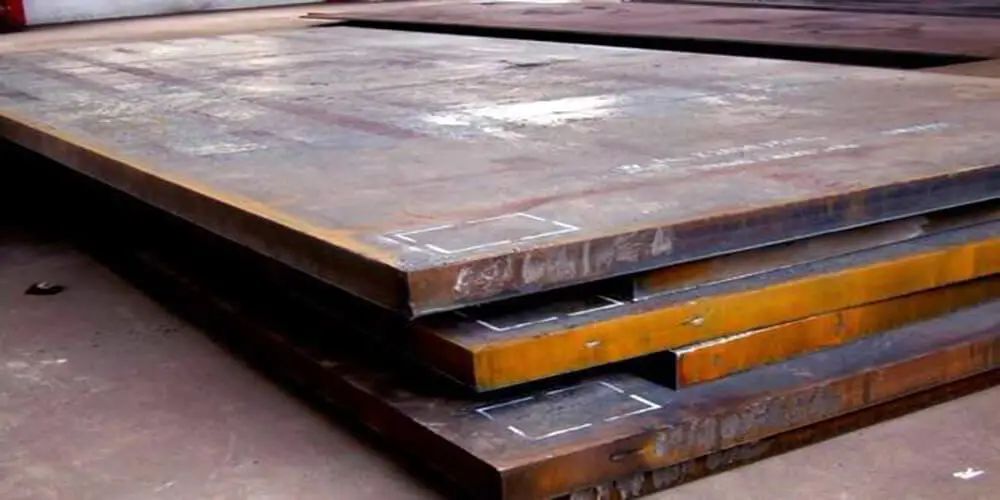

ABREX 600 STEEL PLATE SPECIFICATION

Thickness : 5mm to 150mm

Width : 1,500mm to 2,500mm

Length : 6,000mm to 12,000mm

Heat Treatment : N, Q+T

Surface Paint : EP, PE, HDP, SMP, PVDF

Material : ABREX 600 Plate

ABREX 600 CHEMICAL COMPOSITION

|

Plate |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

B |

CEV |

CET |

|

thickness mm |

max % |

max % |

max % |

max % |

max % |

max % |

max % |

max % |

max % |

typv |

typv |

|

8-30 |

045 |

0.7 |

1.00 |

0.015 |

0.01 |

1.2 |

2.5 |

0.8 |

0.004 |

0.73 |

0.55 |

|

(30)-50 |

0.47 |

0.7 |

1.00 |

0.015 |

0.01 |

1.2 |

2.5 |

0.8 |

0.004 |

0.84 |

0.59 |

ABREX 600 MAXIMUM CARBON EQUIVALENT CET (CEV)

| Thickness (mm) | 8.00 – 24.99 | 25.00 – 65.00 |

| Max CET(CEV) | 0.58 (0.76) | 0.61 (0.87) |

ABREX 600 MECHANICAL PROPERTIES

|

Grade |

Mechanical Property |

Charpy V Impact Test |

||

|

ABREX 600 |

HBW |

Elongation |

Degree |

longitudinal |

|

Min Mpa |

Min % |

-40 |

J |

|

|

570-640 |

10 |

20 |

||

APPLICATION

Machine building

Pylons and other architectural structures

Lifting and mobile equipment

Construction of bridges

Wearing plates

Framework structures

Crane booms, Rail cars

Stone or iron chutes

Truck frames, Containers

Vehicles and transport equipment

Anti drill plates such as security doors, shot blasting equipment and tumbling machine