FDM stands for the term Fused Deposition Modeling and is the installed base of 3D printers worldwide. FDM 3D printing service is one of the most systematic printing technologies used by the majority. With other existing materials, the prototype of ABS gets manufactured by these FDM services. The parts made by fused modeling are exceptionally sturdy, strong, and robust.

For this particular reason, these parts operate for applications in development and additive manufacturing. In fit and functional check for sample tests, the productivity of ABS parts gets utilized. It gives a smooth finish to the upper portion. It is tricky to put up the lines. Fused modeling is best suited for invisible parts and complicated surface finish. The parts are full of holes that can be sealed by applying chemical components.

Characteristics of FDM Service

There are certain features of the FDM printing service which are:

Technological Outlook

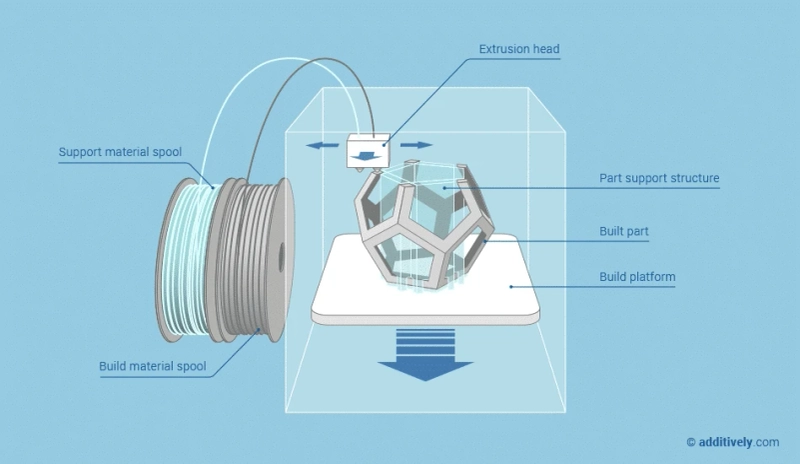

This technology is gaining popularity day by day globally. With numerous systems of production, this technology can give you benefits in many ways. FDM rapid prototypes can read data from STL files. After that, these files are transformed into points of remark to develop new designs. The printer has an in-build envelope in which these models get constructed. Best FDM printing services use filament of thermoplastics continuously in their printers. After tiny beads get emitted, they get placed on the print bed. Once the layer is ready, it is made to stand down. The same procedure repeats every time. Each layer is equally fine and measured.

Technological Highlights

The key feature of this technology is the software that operates fused modeling and allows the users to control everything. In the printing process system, this feature is helpful in various aspects for the users, including fill density which needs to be inserted into the model. It will get printed afterward. The fused model prototyping takes responsibility for a few low and rough densities of the fill as per the demand of the last use. The front layer facing downward gets aided while the processing of support material goes on. If you leave important parts behind, the process gets terminated.

The Considerable Benefits

According to their measurements, the fused modeling elements are steady and secured. They continue maintaining their material properties and perfection with time. These mentioned parts can be built with the assistance of confirmed materials and are used in medical applications and the food industry. Some ideal parts are even customized appropriately for the aircraft.

The applied raw materials in this fused modeling process get produced with excellently supported structures. This characteristic primarily helps in making this technology pocket-friendly. One can handle a fused modeling machine with no difficulty as it is easily accessible.

End Thought

FDM printing technology has become advanced and updated in recent years. With the help of efficient FDM printing services, one can achieve many benefits in several ways. It works flawlessly, is available, and is not costly at all.