The Sewage Treatment Plant (STP) facility is set up to treat the effluents with organic impurities biologically. There is lot of organic materials in the wastewater. Direct discharge of effluent into water bodies causes the water's DO to be depleted. As a result, to meet the specified effluent quality criteria, the effluent must be treated before being disposed off. The primary contaminants in the wastewater are removed at this treatment facility. If you are looking for setting up a Sewage Treatment Plant and searching for the best STP Plant Manufacturers and Supplier then one name that you can trust with full conviction is Green Genra, a group led by a brilliant set of Environmental Engineers, and have been providing one of the best services in this domain.

The raw effluent contains a high concentration of suspended particles as well as oxygen-depleting organic matter. The treatment's conceptual approach involves the removal of suspended particles, dissolved organic materials, and the disposal of sludge.

The main objectives of STP are to ensure pollution-free wastewater disposal standards, to decrease wastewater output at the source, to treat wastewater with the lowest possible operating and maintenance costs. The wastewater treatment process must be installed in a limited footprint area and to obtain reusable quality from an STP process at a lower Opex and Capex.

Main units of Sewage Treatment Plant based on MBBR Technology are:

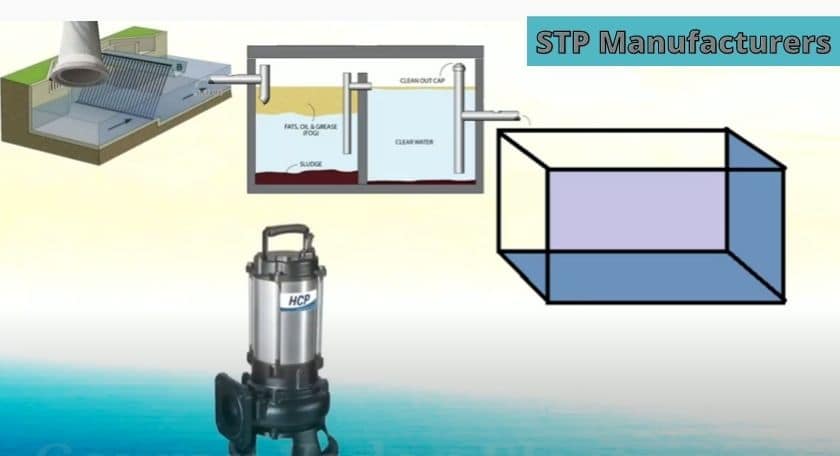

1) Equalization Tank – The equalization tank's purpose is to balance the raw effluent from various processing units and damp down the fluctuations in the incoming wastewater flow rate.

2) Aeration Tank/ Moving Bed Bio Reactor Tank – Sewage is pumped through pumps at the average flow to the MBBR unit. The organic matter present in the Sewage gets decomposed biologically with help of Aerobic bacterial culture on special media in presence of air. The required air will be provided with help of Twin lobe air blower and fine bubble air diffusion grid. The biological impurities will be converted into sludge flocs.

3) Clarifier – It is necessary to separate the decomposed organic matter from the treated effluent. The agglomerated mass of organic matter and activated bacteria i.e. Activated sludge is settled in this tank by specially designed tube deck media to increase the contact surface area. The sludge settles in this tank

4) Clear Water Tank: The treated effluent from Clarifier is transferred to a clear water tank. The effluent is then passes through Pressure filters, Dual Media Filter and Activated Carbon Filter. Fine Suspended particles are removed in Dual Media Filter. Odour Removal, Colour Removal is done in the ACF.

5) UV Disinfection: Effluent of ACF unit is collected to Treated Water Tank where U.V. Disinfection system is installed to achieve desired levels of disinfection.

6) Sludge Drying Beds- The purpose of this device is to dewater and dry surplus biological sludge.

We specialise in supplying custom made units too but some of our standard models are listed below:

Some of our standard models apart from the custom designs:

Model number: GG-STP10

Capacity: 10000 Litres/Day

Price: Rs. 5,00,000 onwards

Model number: GG-STP20

Capacity: 20000 Litres/Day

Price: Rs. 8,00,000 onwards

Model number: GG-STP40

Capacity: 40000 Litres/Day

Price: Rs. 11,00,000 onwards

Model number: GG-STP50

Capacity: 50000 Litres/day

Price: Rs. 12,50,000 onwards

Green Genra offers a variety of basic STP units, but we also specialise in custom-designing units to meet our clients' specific needs. We have one of the most competitive pricing structures in the market, and the quality of our goods and services stems from the fact that we are a company run by environmental engineers that understand the nature and requirements of the industry, and this is where our success resides.