Its numerous distinct advantages make it a crucial technological advancement in many fields. Machinists may reshape and rebuild existing components using CNC machine service company, which saves them time and effort compared to traditional methods. When manufacturing anything from scratch, they use CAD (computer-aided design) software, allowing them to develop complex strategies while wasting as little material as possible.

By eliminating the need for human operators and using the computer\'s automated features, this machining may save time and money. Depending on the context, other significant distinctions become apparent. The advantages of cnc machining services will be discussed in this article.

Increased Accuracy and Superior Completion

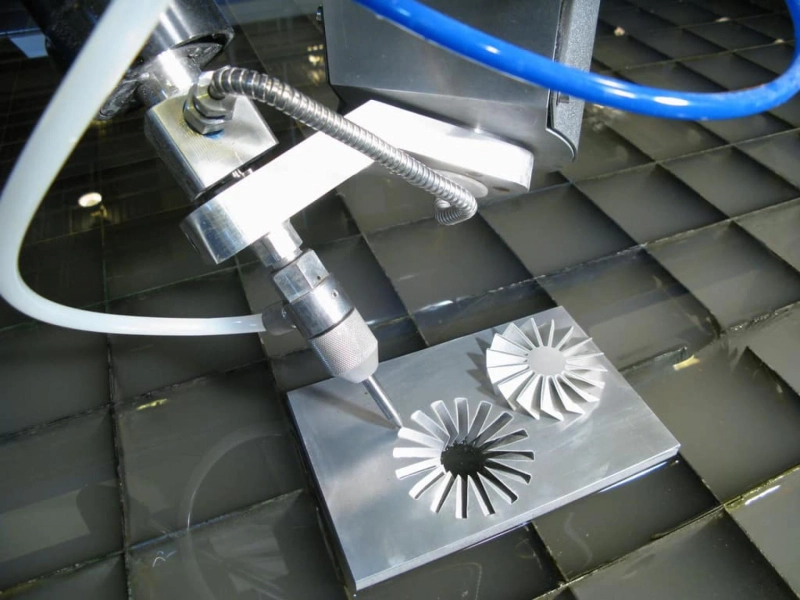

The controller used in CNC machining services directly affects its precision. Accuracy increases with a controller equipped with a more precise positioning mechanism. Traditional machining techniques are only as exact as the man controlling them is. The item must undergo further procedures like grinding and polishing to have a flawless surface finish after machining. Manually guided conventional machining can only achieve results as precise as its operator can. In part, improved precision in CNC machining is possible by using a controller with a higher degree of accuracy in its placement.

CNC Machining Eliminates Flaws And Improves Precision

Accuracy is a big plus of CNC machining. Because CNC machines are programmed with such precision and their motions are controlled by computers, the final product is guaranteed to be consistent and closely resemble the digital prototype. When it comes to making precision components, this is a significant benefit. With this feature, mistakes made by humans are almost eliminated.

Error-Free and Precise to the Last Detail

Precision-turning machines eliminate the potential for mistakes caused by human production errors since they function independently and need no human interaction. The devices can perform with higher precision and zero defects thanks to the codes and algorithms that regulate the whole procedure.

And, barring intentional changes, these inputs don\'t alter much from cycle to cycle. Thus, end outputs are consistently reliable as well. In addition, the machines can work continuously for extended periods without ever lowering their output standard. It lowered manufacturing expenses thanks to computer numerical control machining. In addition, 3d CNC machining services require less material than traditional milling. Cantering your shop on cnc technology may reduce errors, manufacturing expenses, and product prices.

Conclusion

CNC machine repair services have many benefits over traditional machining methods. A few examples are greater design flexibility, finer details, and improved accuracy.