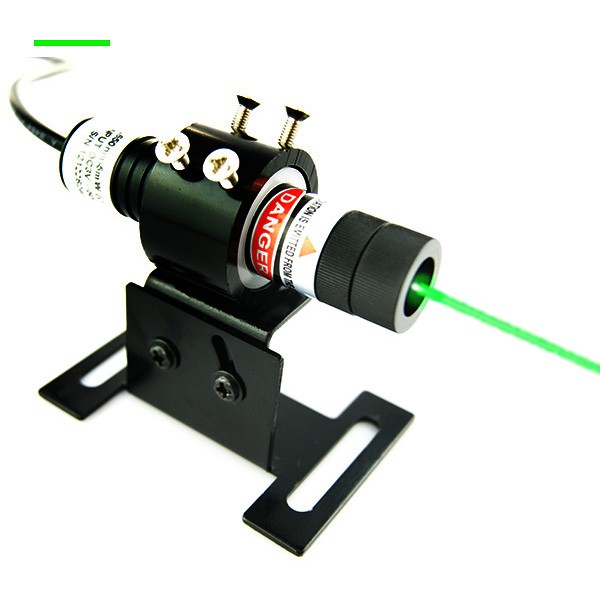

In current type of highly precise and accurate enough line projection onto various work distances, even though it is not easy to reach by manual line printing device, it should not be an easy job before selecting a quite practically used device. As a result, the use of 532nm green line laser alignment makes good use of advanced 532nm green DPSS laser tech and qualified glass coated lens or separate crystal lens with different fan angles. According to its proper installation and adjustment to correct position, this laser line generator makes sure of highly fine and straight green line indication onto all working surfaces.

Real work distance, high height and other complex working environments do not limit the usual use of line projection with a 532nm green line laser alignment. When it is projecting highly visible green laser beam, after getting the lowest laser beam divergence of less than 1mard, it is projecting super fine and straight green reference line onto multiple working surfaces. This laser line generator gets wide range output power of 5mW to 100mW, after proper use of 5V, 9V 1000mA DC power supply, it is keeping work with continuous line alignment as long as 25 meters and other high lighting working occasions as well.

In various industrial and high tech line measuring work fields, in order to project various line lengths and line finenesses onto different working surfaces, this 532nm green line laser alignment enables freely selected optic lens degree. It is able to choose glass coated lens or separate crystal lens, either it is projecting Gaussian beam or non Gaussian distribution green laser beam, this laser line generator is still projecting highly straight green line. Within wide range optic lens degree of 10 degree to 110 degree, only if it makes correct measurement and experiment of technical data, it would get correct optic lens degree and make the most precise green line positioning results.

According to the use of APC, ACC driving circuit board, the genuine line measuring work of 532nm green line laser alignment is preventing any possibility of tube burning out or damage. Only if it keeps work within 8 to 10 hours, after enough time leaving for tube cooling down, and proper adjustment of laser beam focus, this industrial alignment laser enables the most rapid green laser light focusing and the finest green line projection constantly. When users are paying high attention to any thermal energy hurt to human eyes and wearing proper laser safety glasses, a high power green line laser is still making safe and clear dot alignment constantly.