- § Quick administration of drugs, which is especially beneficial in emergency situations.

- § Reduced cost of manufacturing; it is worth highlighting that plastic prefilled syringes are more affordable. Moreover, these syringes are less prone to damage (cracking or breakage) compared to their glass counterparts.

- § Reduced time for fill / finish due to availability of ready to fill, pre-sterilized containers.

- § Reduced drug overfills, helping manufacturers further optimize on overall expenditure (by preventing product loss during fill / finish). For a 0.5 ml vial, the United States Pharmacopeia (USP) recommends 20%-25% overfill, whereas the required overfill is < 2% for a 0.5 ml prefilled syringe.

- § Higher filling line efficiency, compared to vials, with use of modern automated filling technology, such as barrier isolation systems.

- § More robust and versatile drug delivery device (compared to vials), with the potential to be marketed at premium prices. This is likely to directly impact the revenue generation potential of developer companies.

-

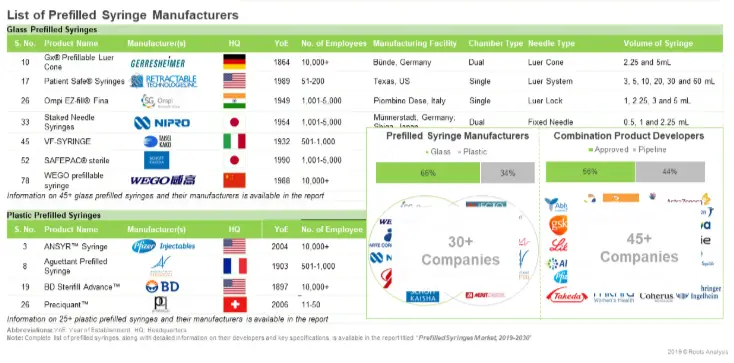

The market is featured by the presence of across 30 companies that are presently manufacturing different types of prefilled syringes. The industry is dominated by a handful of large and well-established players; the Asia-Pacific region is one of the key hubs for prefilled syringe manufacturers. Moreover, majority of the companies (56%) have manufacturing facilities in Asia-Pacific; among these, five companies have facilities in Japan followed by four companies with facilities in China.

During our research, we identified 100 prefilled syringes that are available / under development for delivery of different types of drug molecules. Majority (~70%) of such syringes have glass barrels, while the remaining have plastic barrels. A large proportion (84%) of prefilled syringes have a single chamber and very few companies manufacture dual chamber prefilled syringes. Examples of dual chamber prefilled syringes include (in alphabetical order, no selection criteria) Companion Dual Chamber Reconstitution Syringe, Dual Chamber PrefillableTM Syringe, FULJECT Passive Type Syringe, Lyo-DCPS and PC-Lyo.

Owing to the benefits listed above, applications of prefilled syringes have extended to new indications, such as rheumatoid arthritis and multiple sclerosis. Prefilled syringes market is one of the fastest growing markets in drug delivery and pharmaceutical packaging industry. Despite the large number of benefits offered by them, limitations with the use of prefilled syringes still exist, leaving room for further technological improvements. Manufacturers of prefilled syringes are continuously looking for innovations in technologies and materials to enhance the benefits and applications of prefilled syringes. Incorporation of new design features and technical improvements to meet the needs of healthcare industry promises to maintain dominance of prefilled syringes in drug delivery market.