Our Rollstock thermoformers are widely used by the industrial and packaging sectors worldwide to produce high-quality packaging. When they are utilized, one of the most adaptable package varieties now available is produced. When choosing Rollstock Thermoforming machines, there are several considerations to make.

Minimal Cost of Operations

Using rollstock machinery lowers the cost of packaging your finished goods. Because this machine molds the container, fills it with product, and closes it in-line, it generates less waste than older packaging methods.

Faster Packaging Rates

When using Roll stock termoformer, more packages can be created in a minute than when using a vacuum chamber machine to manually fill and seal them. A common question from prospective customers is “How fast can this machine run?” “How fast can you Load it?” is our standard response.

Adaptability in Packaging

Rollstock thermoformers can produce a wide range of package shapes and sizes. To add a new product package, it could only be necessary to create new tooling dies. Tooling dies make it easy to switch them between product runs, so you can effectively meet all of your needs both now and in the future.

Reduced Labor Costs

Rollstock thermoformers are automated, which eliminates the need for hiring labor to manage and transfer goods between each step of the rollstock process.

Robustness and Extended Product Life

Rollstock Thermoformers create sturdy, long-lasting packaging that extends the shelf life of the goods. Their packaging provides the best possible protection for the contents and is perfect for storing a variety of goods.

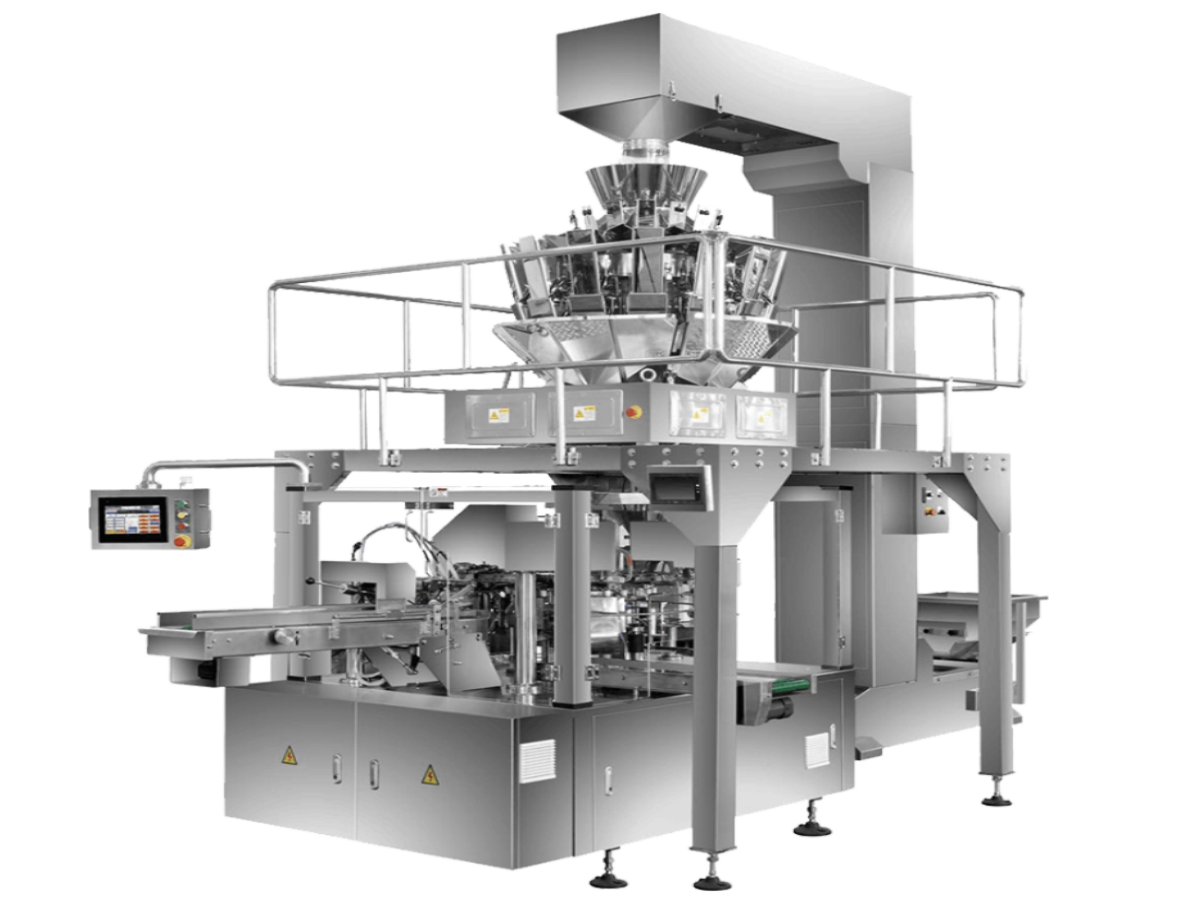

Rollstock machines are designed to package commodities in an efficient and cost-effective way, including food and medical supplies. Experience our state-of-the-art, highly effective rollstock machines, which are customised to your unique needs and made with the fast growing food sector in mind. These simple diagrams were created to aid in the recognition and understanding of the fundamental function and naming convention of these rollstock key parts. Knowing the major components of your thermoformer can help you maintain and operate it more efficiently. You must identify yourself appropriately if you want to keep your unit maintained.