The field of Carbon Fiber 3D Printing is expanding within the Additive Manufacturing industry, and carbon fiber is popularly used in 3d printing service. As this material gains in popularity, it has become evident that Carbon Fiber 3D Printing possesses better features and expanded versatility that make it preferable in certain manufacturing situations.

Benefits Of Carbon Fiber 3D Printing

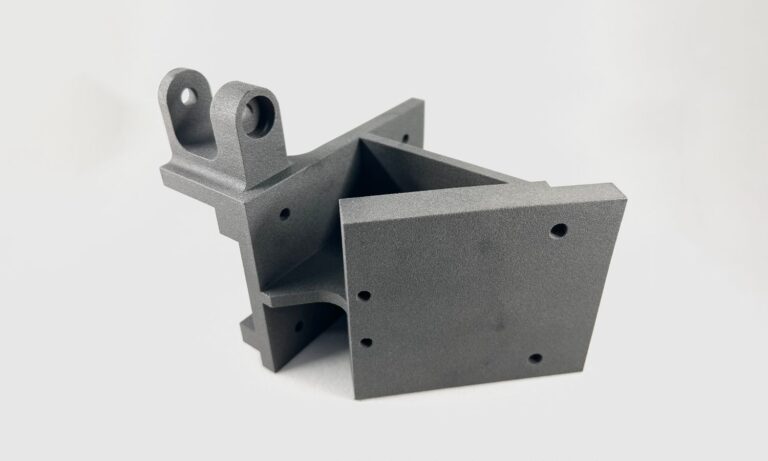

- carbon fiber 3d printing services utilize a composite material comprised of chopped carbon fiber and polymer. In some applications, the mixture of these two materials produces a printing medium that approaches traditionally made aluminum components.

- Carbon Fiber-printed components are lightweight and strong, making them more suitable for prototyping because they meet customer requirements for strength while exceeding heavier materials in weight.

- Carbon Fiber 3D-printed parts have the possibility of replacing aluminum parts in specific manufacturing circumstances without sacrificing strength due to their high stiffness-to-weight ratio. Here is the top usage for which we observe consumers use this content

Tooling Efficiency

In addition to the performance advantages of lighter carbon fiber printing service parts, the unique features of additive manufacturing allow designers to have fewer design constraints.

It enables designers to enhance parts for operator quality and protection by increasing their ergonomic effectiveness. By making components lighter and comfier, designers can reduce the strain on manufacturers and suppliers, and other manufacturing personnel. You must ensure to use the best carbon fiber 3d printer.

Carbon Fiber 3D printing enables lighter items and more organic shapes than conventional manufacturing, which is particularly advantageous for 3D printed tooling requiring operator interaction. Utilizing the advantages of Carbon Fiber printing without losing strength allows for the creation of optimally ergonomic layouts for operator use.

Functional Modeling

Carbon Fiber 3D printing can be used to generate prototypes that not only establish the designer's idea but also enable the designer to test the part's functionality under real-world strain and mobility.Carbon Fiber's exceptional strength and endurance provide this material with the structural rigidity required to endure real-world testing.

This property of Carbon Fiber printing contributes to the adaptability of this manufacturing method, as several iterations of a product's design are frequently necessary before its completion. Further demonstrating the time-saving advantages of Carbon Fiber printing, the prototype may begin as soon as the print is finished.

End-Use Components

Taking the usefulness of Carbon Fiber printing one stage further, some businesses have been able to adapt end-use products using the performance advantages of Carbon Fiber. Carbon Fiber's contribution to the progress of materials through 3D Printing is quite fascinating. Carbon Fiber 3D printing services greatly expand what clients and users can do with this fantastic technology.